You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Inside a Handytig 200

- Thread starter Jetex

- Start date

HughF

Member

- Messages

- 6,460

- Location

- Work: Dorchester, Workshop: Corfe Castle, Wife's place: Frome

I spy a Ti tms320dsp doing the heavy lifting and a lattice cpld/fpga doing some extra lifting or interfacing. Clock frequency is 100MHz, probably running faster than that via a pll though.

I wonder how they do the pfc, I don’t see a large bank of D.C. storage capacitors after the primary rectifier, which is nice.

I wonder how they do the pfc, I don’t see a large bank of D.C. storage capacitors after the primary rectifier, which is nice.

One thing that really puzzles me is why tig welders are so expensive. Especially the high end inverter types. I can understand the old transformer types costing so much but how can they justify say £8,000 for some of the millers?

That Lorch sells for £2,000 but I bet it costs about £200 to £300 to manufacture! Probably even less!

That Lorch sells for £2,000 but I bet it costs about £200 to £300 to manufacture! Probably even less!

HughF

Member

- Messages

- 6,460

- Location

- Work: Dorchester, Workshop: Corfe Castle, Wife's place: Frome

It’s because-they-can...One thing that really puzzles me is why tig welders are so expensive. Especially the high end inverter types. I can understand the old transformer types costing so much but how can they justify say £8,000 for some of the millers?

Jetex

Member

- Messages

- 163

- Location

- Luton, England

Yes, there is defiantly a big profit from just the bill of materials but it would seem that a lot of time and work goes in the development of these inverter welders. It is still a small scale business in comparison to manufacturing TV's or mobile phones etc.

Jetex

Member

- Messages

- 163

- Location

- Luton, England

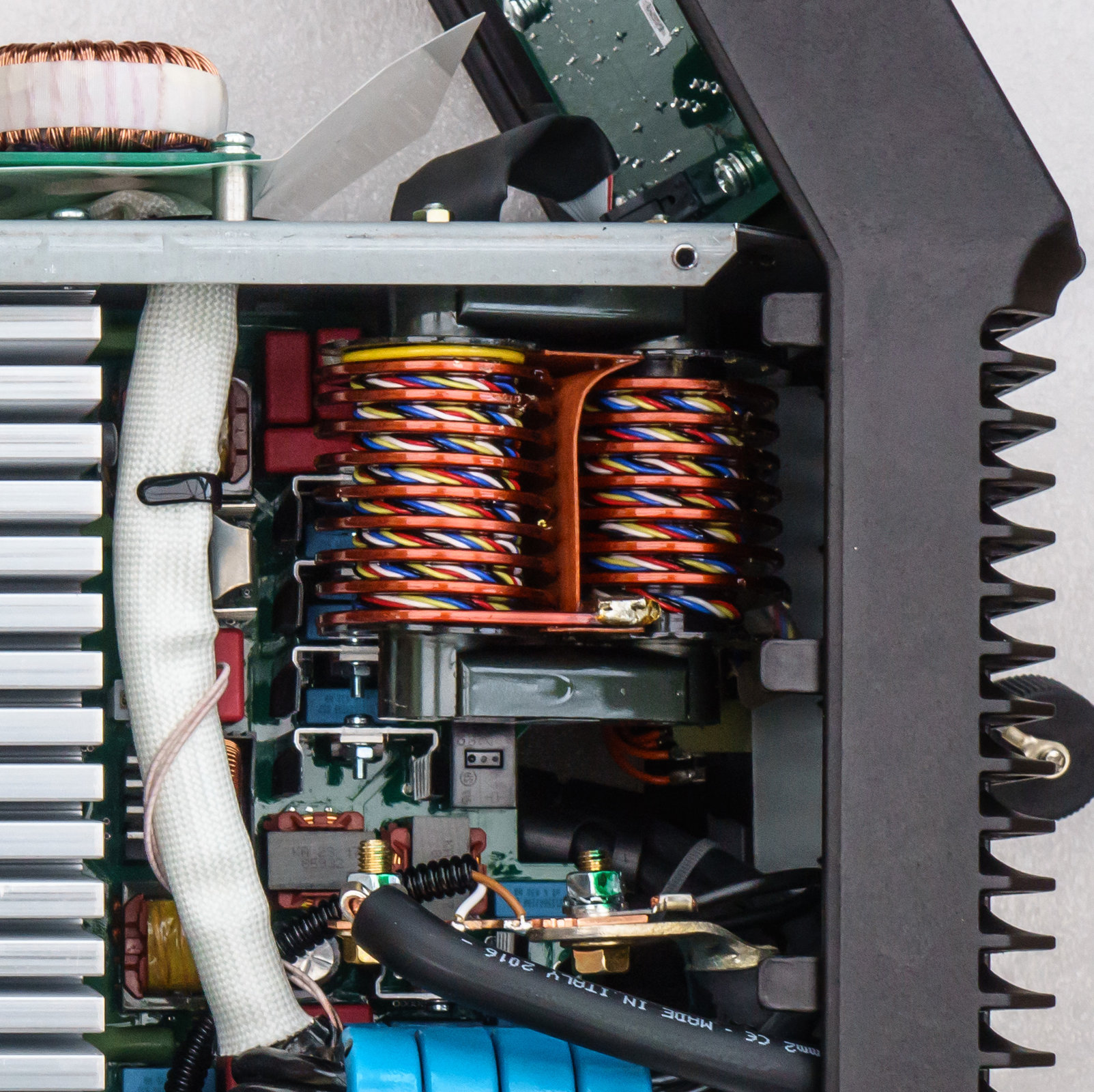

One thing I found interesting is that the torch switch wires from the front connector are all are wrapped around the HF coil, does anyone know the purpose of this? This front connector has connections for a smart tig torch or twin button tig torch. Those are the red, white, yellow, blue and black wires in between the copper coils. I had a plan to change the front 5 pin connector and rear 14 pin connector to something better and more freely available.

- Messages

- 14,356

- Location

- UK

One thing that really puzzles me is why tig welders are so expensive. Especially the high end inverter types. I can understand the old transformer types costing so much but how can they justify say £8,000 for some of the millers?

That Lorch sells for £2,000 but I bet it costs about £200 to £300 to manufacture! Probably even less!

Research, development, testing, marketing, insurances, etc etc there is an endless list, not just the prices of the parts and putting them together

slim_boy_fat

Forum Supporter

- Messages

- 29,501

- Location

- Scottish Highlands

Research, development, testing,

The same as pharmaceuticals

frank horton

V twins are great but 4"s rule.........

- Messages

- 3,848

- Location

- Crete, Greece

what happened to economy of scale......????? love a TIG but just can't justify the price let alone the time to master it........

will wait for a price drop.........hahaha..........Frank

will wait for a price drop.........hahaha..........Frank

Richard.

Member

- Messages

- 18,347

- Location

- Cambridgeshire

They are certainly not overpriced

An average price for a high end single phase inverter is around 2800-3000. Used to it’s potential it’s gonna buy itself back in no time. Looked after it’s gonna last 10-15 years and of bought itself back many many many times over. People who say millers are over priced clearly haven’t owned one. The miller tig sets are one of the best in the world. I’ve used both a syncrowave and a dynasty and although they are very different machines they both share beautiful arc characteristics.

My machine is a tweco arcmaster 220 also built by lorch. It holds a price tag of over £3000 and once you’ve owned such a machine you can really see why they cost what they do.

An average price for a high end single phase inverter is around 2800-3000. Used to it’s potential it’s gonna buy itself back in no time. Looked after it’s gonna last 10-15 years and of bought itself back many many many times over. People who say millers are over priced clearly haven’t owned one. The miller tig sets are one of the best in the world. I’ve used both a syncrowave and a dynasty and although they are very different machines they both share beautiful arc characteristics.

My machine is a tweco arcmaster 220 also built by lorch. It holds a price tag of over £3000 and once you’ve owned such a machine you can really see why they cost what they do.

Richard.

Member

- Messages

- 18,347

- Location

- Cambridgeshire

It looks a very clean machine almost brand new. If it’s still under warranty the last thing you want to be doing is changing connections over with ones you prefer. If you have a problem whether it’s related or not the likelihood is your warranty will be void because you’ve had your fingers in there and modified it. Those plugs and sockets will be high quality ones like the rest of the machine and they are easy enough to get hold of. Why would you want to change them for cheaper ones.One thing I found interesting is that the torch switch wires from the front connector are all are wrapped around the HF coil, does anyone know the purpose of this? This front connector has connections for a smart tig torch or twin button tig torch. Those are the red, white, yellow, blue and black wires in between the copper coils. I had a plan to change the front 5 pin connector and rear 14 pin connector to something better and more freely available.

View attachment 126970

HughF

Member

- Messages

- 6,460

- Location

- Work: Dorchester, Workshop: Corfe Castle, Wife's place: Frome

The tms320lf2406 main dsp chip they are using is an interesting design, it has a surprisingly high number of general purpose peripherals and is optimised for motor inverter and power inverter applications, which an inverter Welder obviously is. This is quite different to the older analogue design inverters (my hitachi, the older everlast /r-tech units, the generic 200a Chinese units) which often use an analogue inverter control chip from iirc Freescale semiconductor.

Dayjob is embedded electronics so I find this type of thing interesting.

Dayjob is embedded electronics so I find this type of thing interesting.

Jetex

Member

- Messages

- 163

- Location

- Luton, England

Those plugs and sockets will be high quality ones like the rest of the machine and they are easy enough to get hold of. Why would you want to change them for cheaper ones.

I am not finding them that easy to get hold of, at least at a reasonable price. The front connector is the 5 pin Tuchel type copy. The quality also does not seem that good, there are better quality connectors at a lower price than these. The rear 14 pin one is a TE Amp connector. This one is quite cheap but you buy all the connector parts separate, housing, contact pins, cable grip etc. again there are better choices for this and only 8 contacts are required for a foot pedal.

Your point about warranty is valid but I would swap the whole internal cable so if there was a problem I could easily just swap it back to factory standard.

It is a great welder and welds beautifully but the connectors are the only thing I don't really like about it.

Jetex

Member

- Messages

- 163

- Location

- Luton, England

People who say millers are over priced clearly haven’t owned one.

That's fair enough and its true I have never owned one.

Richard.

Member

- Messages

- 18,347

- Location

- Cambridgeshire

Your not wrong there. I’ve used brads ht200 and it’s simply stunning to use. Lovely on ac.It is a great welder and welds beautifully but the connectors are the only thing I don't really like about it.

Technology usually drives prices down. I still fail to see how a high end TIG welder can cost as much as a car or a motorbike. The actual manufacturing costs are far far lower - and the other manufactures have to invest in R+D as well.

As someone said - it is because they can. I suspect the likes of miller sell most of their stuff to government/military institutions who don't care how much they cost.

I am NOT saying they don't make the best products - just the profit margins are eye watering!

As someone said - it is because they can. I suspect the likes of miller sell most of their stuff to government/military institutions who don't care how much they cost.

I am NOT saying they don't make the best products - just the profit margins are eye watering!

daleyd

Member

- Messages

- 9,832

- Location

- Wrexham, North Wales

Technology usually drives prices down. I still fail to see how a high end TIG welder can cost as much as a car or a motorbike. The actual manufacturing costs are far far lower - and the other manufactures have to invest in R+D as well.

As someone said - it is because they can. I suspect the likes of miller sell most of their stuff to government/military institutions who don't care how much they cost.

I am NOT saying they don't make the best products - just the profit margins are eye watering!

But it’s not just the manufacturing costs - what about research and development, producing nice manuals with proper pictures etc, quality testing, satisfying iso standards, having a manned Helpdesk to answer customer queries - the list is (almost) endless.

The company I work for is in the same boat - you can buy a generic Chinese temperature controller that will do 75% of what our equivalent will do for about £15, whereas ours would cost you nearer £200. Ours would cost marginally more to build simply because of the better manufacturing process but the majority of that extra money that your paying for would be in the stuff that you can’t see.