- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I have just purchased a Boxford Lathe

- Thread starter 123hotchef

- Start date

123hotchef

Member

- Messages

- 14,347

- Location

- Kent

Thanks guys I shall fit a simple tap then and see what happens first. I do have 3 if those flexi spouts with taps on the base

But I can't find them

But I can't find them

Laurie Tedcastle

Forum Supporter

- Messages

- 145

- Location

- NW Northants (UK)

@123hotchef

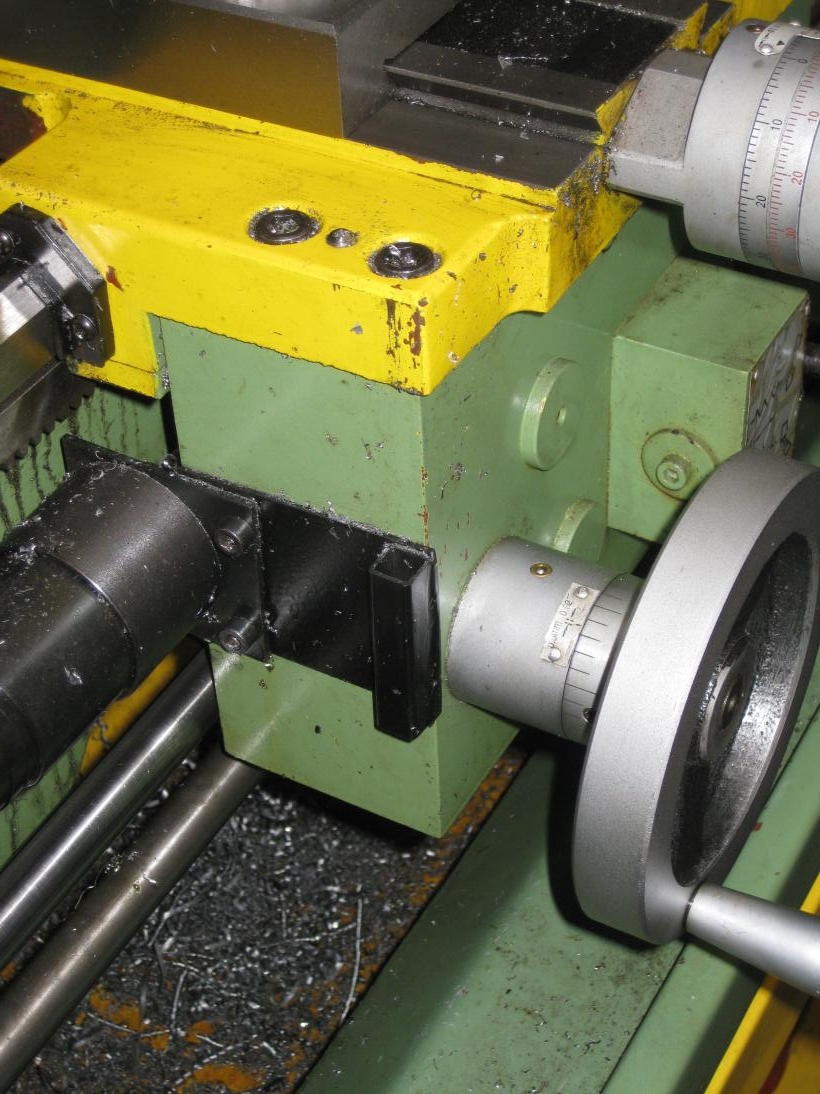

pair of quick & dirty guards I fitted to my lathe to avoid coolant splashing. Left fixed to the headstock, right to the apron.

When working closer to the headstock, the RH one slides inside the LH:

The guards are easily removed when not needed. Bracket on the apron:

Reverse side of the apron guard:

Also have a and adjustable extension of the chuck guard:

Laurie

pair of quick & dirty guards I fitted to my lathe to avoid coolant splashing. Left fixed to the headstock, right to the apron.

When working closer to the headstock, the RH one slides inside the LH:

The guards are easily removed when not needed. Bracket on the apron:

Reverse side of the apron guard:

Also have a and adjustable extension of the chuck guard:

Laurie

123hotchef

Member

- Messages

- 14,347

- Location

- Kent

Thanks @Laurie Tedcastle I like that idea especially the sliding extension too. So the guard has a piece on the rear that slots into the box section attached to the apron does it.@123hotchef

pair of quick & dirty guards I fitted to my lathe to avoid coolant splashing. Left fixed to the headstock, right to the apron.

When working closer to the headstock, the RH one slides inside the LH:

View attachment 197664

The guards are easily removed when not needed. Bracket on the apron:

View attachment 197668

Reverse side of the apron guard:

View attachment 197669

Also have a and adjustable extension of the chuck guard:

View attachment 197670

Laurie

123hotchef

Member

- Messages

- 14,347

- Location

- Kent

Sorry just saw the next pic looks like a piece of Ali rivited on. I might have to borrow that idea if I keep getting coolant running over the handle and onto the floor

Laurie Tedcastle

Forum Supporter

- Messages

- 145

- Location

- NW Northants (UK)

They are domed head hex drive screws (not rivets) fixing the steel sheet to the peg which slots into the socket. Same for the headstock one, just didn't bother to photo it. The guards mostly stay in place, but are lifted off when tapping, changing chucks, etc.

Design was the quickest/easiest I could come up with at the time. Would really have liked a big sliding guard like we had on the Herbert turret lathes, but it would have been mega amount of work. If your not familiar with the Herbert lathes have a look at the sliding guard on Hood's Computurn thread.

I also had to extend the rear splash guard vertically to prevent cutting oil getting sprayed over the back of the lathe.

Laurie

Design was the quickest/easiest I could come up with at the time. Would really have liked a big sliding guard like we had on the Herbert turret lathes, but it would have been mega amount of work. If your not familiar with the Herbert lathes have a look at the sliding guard on Hood's Computurn thread.

I also had to extend the rear splash guard vertically to prevent cutting oil getting sprayed over the back of the lathe.

Laurie

123hotchef

Member

- Messages

- 14,347

- Location

- Kent

How did u fit the box section that the guard slides into on to the apronThey are domed head hex drive screws (not rivets) fixing the steel sheet to the peg which slots into the socket. Same for the headstock one, just didn't bother to photo it. The guards mostly stay in place, but are lifted off when tapping, changing chucks, etc.

Design was the quickest/easiest I could come up with at the time. Would really have liked a big sliding guard like we had on the Herbert turret lathes, but it would have been mega amount of work. If your not familiar with the Herbert lathes have a look at the sliding guard on Hood's Computurn thread.

I also had to extend the rear splash guard vertically to prevent cutting oil getting sprayed over the back of the lathe.

Laurie

Laurie Tedcastle

Forum Supporter

- Messages

- 145

- Location

- NW Northants (UK)

@123hotchef

Look at the 2nd pic I posted. The square tube is plug welded (I think - it's been a long time now) to a piece of 3mm plate, which in turn slides between the telescopic leadscrew guard end plate and the apron using the original telescopic guard mounting screws. You may have drill & tap some holes in the apron wall if your lathe doesn't have a suitable mounting point. I did have to drill & tap for the headstock guard mounting. Each lathe is different, of course, so you just have to exercise the old grey cells to sort something that works for you. Some are reluctant to modify their equipment. If I think

of an improvement, I'll do it.

Laurie

Look at the 2nd pic I posted. The square tube is plug welded (I think - it's been a long time now) to a piece of 3mm plate, which in turn slides between the telescopic leadscrew guard end plate and the apron using the original telescopic guard mounting screws. You may have drill & tap some holes in the apron wall if your lathe doesn't have a suitable mounting point. I did have to drill & tap for the headstock guard mounting. Each lathe is different, of course, so you just have to exercise the old grey cells to sort something that works for you. Some are reluctant to modify their equipment. If I think

of an improvement, I'll do it.

Laurie

Laurie Tedcastle

Forum Supporter

- Messages

- 145

- Location

- NW Northants (UK)

Pic from the rear of the extended splashback:

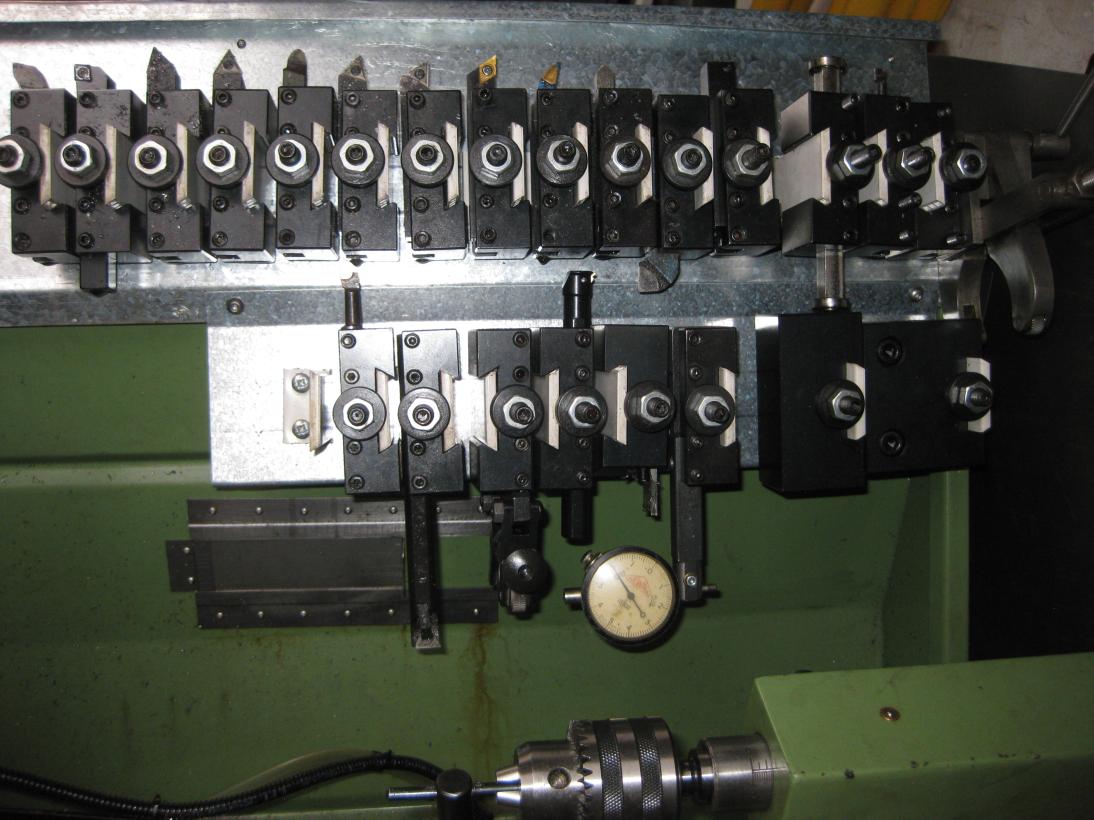

and from the front, the extra space gets used for toolholder storage:

Laurie

and from the front, the extra space gets used for toolholder storage:

Laurie

123hotchef

Member

- Messages

- 14,347

- Location

- Kent

123hotchef

Member

- Messages

- 14,347

- Location

- Kent

its never enough though is it!That's a whole lot of tools!

I gave the lathe some love tonight andnipped up the screws on the top slide and cross slide now I have no play!

I reakon it will be even better to use now especially with the new parting tool

123hotchef

Member

- Messages

- 14,347

- Location

- Kent

Question, how often should I be greasing

1 the head stock bearings

2 the motor bearings

1 the head stock bearings

2 the motor bearings

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

I've not regressed my motor since I replaced the bearings 9 years ago. I must remember to give the headstock a squirt

123hotchef

Member

- Messages

- 14,347

- Location

- Kent

I do the head stock once a month or so but it don't get used a lot but then it gets a hammering. So probably equates to a squirt every 5 or 6 hours use.

As for the motor it has been ages I mean 2 years perhaps

As for the motor it has been ages I mean 2 years perhaps

RWD3M

Forum Supporter

- Messages

- 3,965

- Location

- Wiltshire, UK

You'll not likely know if you're greasing up too often but you'll sure as hell know when you're not greasing it enough!I do the head stock once a month or so but it don't get used a lot but then it gets a hammering. So probably equates to a squirt every 5 or 6 hours use.

As for the motor it has been ages I mean 2 years perhaps

123hotchef

Member

- Messages

- 14,347

- Location

- Kent

always the way that aint itYou'll not likely know if you're greasing up too often but you'll sure as hell know when you're not greasing it enough!

123hotchef

Member

- Messages

- 14,347

- Location

- Kent

Right people thread resarection!

I want to get into cutting threads on this boxford as I have a few projects.

First one calls for metric threads.

I have the change wheels they are much bigger than the ones on the gearbox.

Well I presume that is the gears I swap.

I will upload a few pics.

I want to get into cutting threads on this boxford as I have a few projects.

First one calls for metric threads.

I have the change wheels they are much bigger than the ones on the gearbox.

Well I presume that is the gears I swap.

I will upload a few pics.