- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Horizontal mill?

- Thread starter Maker

- Start date

roofman

Purveyor of fine English buckets and mops

- Messages

- 12,964

- Location

- North West with water on 3 sides

Iff your keeping the mill then its going to be the best 35 notes you,ll ever spendI have seen the manual on lathes.co.uk and I l know I really should buy it but £35 seems like a lot for just an instruction manual.

DanielW

Member

- Messages

- 2,250

- Location

- Merseyside Straightjacket user

You can get it direct via PDF format after paying.

http://www.machinemanuals.co.uk/default.asp?cat=Milling Machine Manuals&delivered=348deliver1

http://www.machinemanuals.co.uk/default.asp?cat=Milling Machine Manuals&delivered=348deliver1

DanielW

Member

- Messages

- 2,250

- Location

- Merseyside Straightjacket user

Was this the nan who you were going to lend the money off??It was actually quite nice (as funerals go), my aunt read "She is gone" by David Harkins which was very fitting and moving. Thanks for asking.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

I got a cover off the back of the motor and inside there was a piece of thin, see through, oily paper with information about the motor including connection instructions but it's on the back and it's really faded, I can just make out 2 diagrams showing the points and the words "for low voltage connection, connect..." and "to reverse direction, swap 2 connections". Albeit it's very difficult to see inside but I can only see 3 connections.

. On the bright side, she is with her husband now and isn't in pain any more

. On the bright side, she is with her husband now and isn't in pain any more .

.

No, it was her mum, she got lymphatic cancer a few years ago and it was treated but I think it came back and spread quite badlyWas this the nan who you were going to lend the money off??

. On the bright side, she is with her husband now and isn't in pain any more

. On the bright side, she is with her husband now and isn't in pain any more .

.But make sure he does not get confused with 3 phase 240 volts and single phase 240 volts.You need to take the terminal covers off the motors to check how many wires from the motor are brought to the connection point. Just because it says 440v doesn't mean it won't run on 240v 3 phase. Both my lathe and mill motors stated 440v but had 6 terminals under the covers so I could reconfigure them to run on 230v.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

Yeah, I know, I need an inverter too.But make sure he does not get confused with 3 phase 240 volts and single phase 240 volts.

oilyneil

Member

- Messages

- 170

- Location

- Wiltshire uk

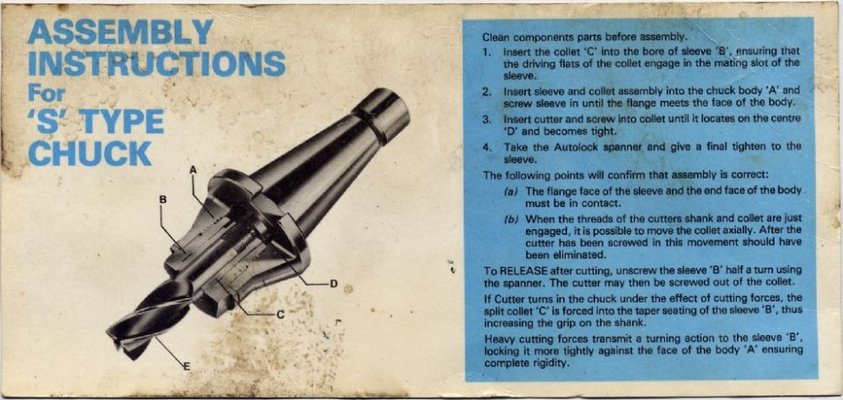

Its a Clarkson Autolock chuck,here are the instructions, you will need to get the correct spanner that fits over the collet holder, depending if you have back gear on the mill you can lock it in to hold the shaft still.View attachment 48271 View attachment 48272 View attachment 48273 View attachment 48274 View attachment 48275

Could someone please tell me how the cutter and collet are changed, i.e, what do I put the spanners on?

Rig Pig

Member

- Messages

- 3,727

- Location

- Narrwich! U.K.

View attachment 48277 View attachment 48276

If I take this cover off, is this where the change gears live?

View attachment 48278

This is the left hand side of the table, there's no handle and the shaft is slightly bent.

View attachment 48279

This is the wires coming out, I'm guessing it's earth and 3 lives (why doesn't 3 phase need neutral?)

View attachment 48280

Coolant pipe, there's a tap behind my thumb and the star knob I assume somehow mounts to a shaft near the head.View attachment 48281 Here's the horizontal spindle and the hanger that goes on the overarm, only problem is it doesn't fit because some knob has hit the overarm with a steel hammer and left a little mark.

I'll have a look inside then. I'd rather not replace the motor because the bearings seem really good and I'd imagine it runs quietly.

I've heard of people breaking the pallet away from underneath it, maybe that's the way forward.[/

You probably don't need to take the boss off, try to tap the broken stub out with a chisel, if that doesn't work drill a hole down the center and use an easy out or equivelent. Nice looking mill.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

That's great, thanks.Its a Clarkson Autolock chuck,here are the instructions, you will need to get the correct spanner that fits over the collet holder, depending if you have back gear on the mill you can lock it in to hold the shaft still.

How do I take the whole chuck out and what is the taper on this machine?

I am so so relieved it all went well.

Things like this are a nightmare if there are no forklifts present.

This is the very limit of what you can send!!!

You said it was wobbly. The ONLY safe way to send something like this is to line the pallet with thick plywood first - then through bolt it.

Things like this are a nightmare if there are no forklifts present.

This is the very limit of what you can send!!!

You said it was wobbly. The ONLY safe way to send something like this is to line the pallet with thick plywood first - then through bolt it.

oilyneil

Member

- Messages

- 170

- Location

- Wiltshire uk

At he opposite end of the chuck (at the top with the head vertical) there is a bolt, looks about 3/4" on yours, undo this a few turns and give it a tap on the top with a copper mallet or dead blow hammer and it should shock the taper out, once it has dropped undo the bolt all the way while holding the chuck to avoid it dropping on the floor or table! When removing or refitting it, give it a wipe with a lint free cloth, on the taper and up in the head to make sure it will seat properly and not damage the taper.That's great, thanks

. How do I take the whole chuck out and what is the taper on this machine?

Looking on here,,

http://www.lathes.co.uk/elliottmillers/page2.html

depending on year it could be 3 morse taper or 30 INT, that should help narrow down the year too.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

Well before the luton it was gonna be a trailerOh and do you think the Luton would have coped lol.....................

balls to that.

balls to that.Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

Hopefully next time I will drive to it and bolt it down properly but I'm still not bringing it home myself, you can do thatI am so so relieved it all went well.

Things like this are a nightmare if there are no forklifts present.

This is the very limit of what you can send!!!

You said it was wobbly. The ONLY safe way to send something like this is to line the pallet with thick plywood first - then through bolt it.

.

.