as some of you may be aware Im building a tiny steam engine and steam plant for a small model boat.

https://www.mig-welding.co.uk/forum/threads/small-steam-engine-for-a-model-boat.98238/

so rather than make a mess of making the model and fitting the engine and then seeing if it needs modifying I decided that it would be better to make a simple model boat to try the engine and steam plant out on. I then decided that I'd see if I could make it out of thin sheet metal (0.9mm zintec). last weekend someone lent me a plan of HMS Instant which as simple as you can get. I jsut hope its not too heavy and doesn't sink, but its the first sheet metal work I've done this year so I could do with the practice. I'll only be making the hull though as I think a metal superstructure might give me issues with getting a signal to the radio control receiver.

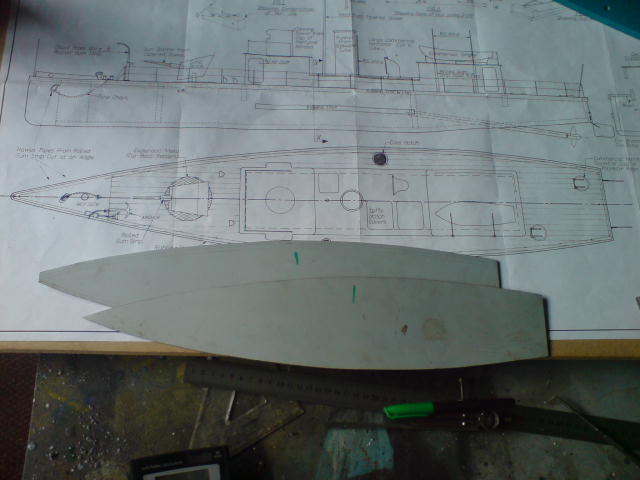

so here is the plan I've started off with and it was reduced to 3/4 of the size to be of similar size to the boat Im making.

as the hull has a flat bottom, flat sides and a flat too, it is simple as it gets. I thought I'd have rounded edges to the bottom of the hull, so the hull bottom is slightly wider than the deck to allow the metal to be formed

so the edges of the hull floor was tipped over using a bead roller

which creates plenty of distortion as the metal has to go somewhere, so to get it roughly flat some of the excess metal in the lip was removed using a shrinker. most of the reshaping was done using hammers and dollies while clamping it to large chunk of metal

and not so far off.

https://www.mig-welding.co.uk/forum/threads/small-steam-engine-for-a-model-boat.98238/

so rather than make a mess of making the model and fitting the engine and then seeing if it needs modifying I decided that it would be better to make a simple model boat to try the engine and steam plant out on. I then decided that I'd see if I could make it out of thin sheet metal (0.9mm zintec). last weekend someone lent me a plan of HMS Instant which as simple as you can get. I jsut hope its not too heavy and doesn't sink, but its the first sheet metal work I've done this year so I could do with the practice. I'll only be making the hull though as I think a metal superstructure might give me issues with getting a signal to the radio control receiver.

so here is the plan I've started off with and it was reduced to 3/4 of the size to be of similar size to the boat Im making.

as the hull has a flat bottom, flat sides and a flat too, it is simple as it gets. I thought I'd have rounded edges to the bottom of the hull, so the hull bottom is slightly wider than the deck to allow the metal to be formed

so the edges of the hull floor was tipped over using a bead roller

which creates plenty of distortion as the metal has to go somewhere, so to get it roughly flat some of the excess metal in the lip was removed using a shrinker. most of the reshaping was done using hammers and dollies while clamping it to large chunk of metal

and not so far off.

please .

please .