Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,866

- Location

- East Yorkshire

Apron reassembled and installed with no problems nor leaks.

After soaking the screw cutting gearbox in kerosene for several days it emerged in pretty much same state so stripped the selector fork, drum and 8 position indexed knob, thoroughly cleaned and reassembled with new o rings. After spending a good hour tweaking the change is very smooth...

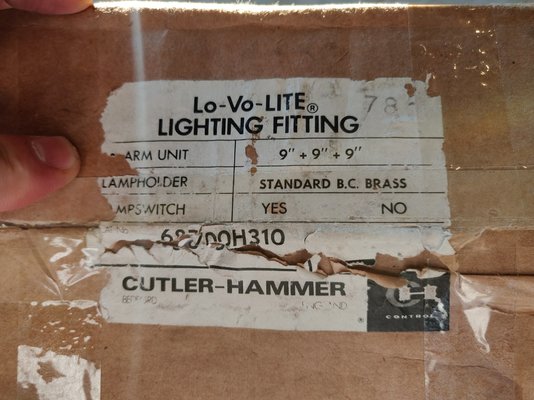

View attachment 226537

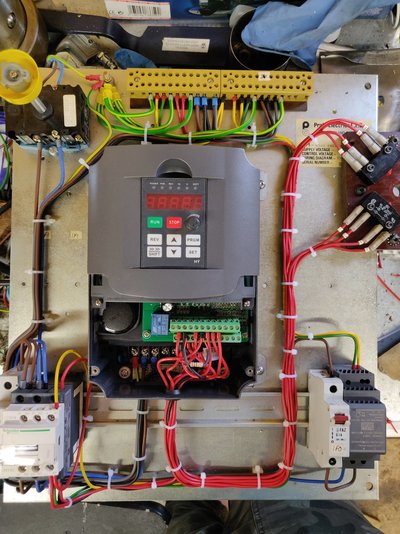

With the screw cutting gearbox reinstalled it was time to wire up the VFD. It's now I'm wishing I hadn't upgraded to a 4kW model - it's massive.

View attachment 226538

I don't want to mount it external to the lathe so I'm going to have to cut a hole in the pedestal wall inside the electrical compartment....a job for tomorrow.

Isthat 4hp per channel. My alen bradley vfd is, takes an age to wind up max rpm. I’ve got a 7.5hp to cure that