You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Final picked up my new project. 1993 1275i Mini Cooper

- Thread starter Exuptoy

- Start date

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

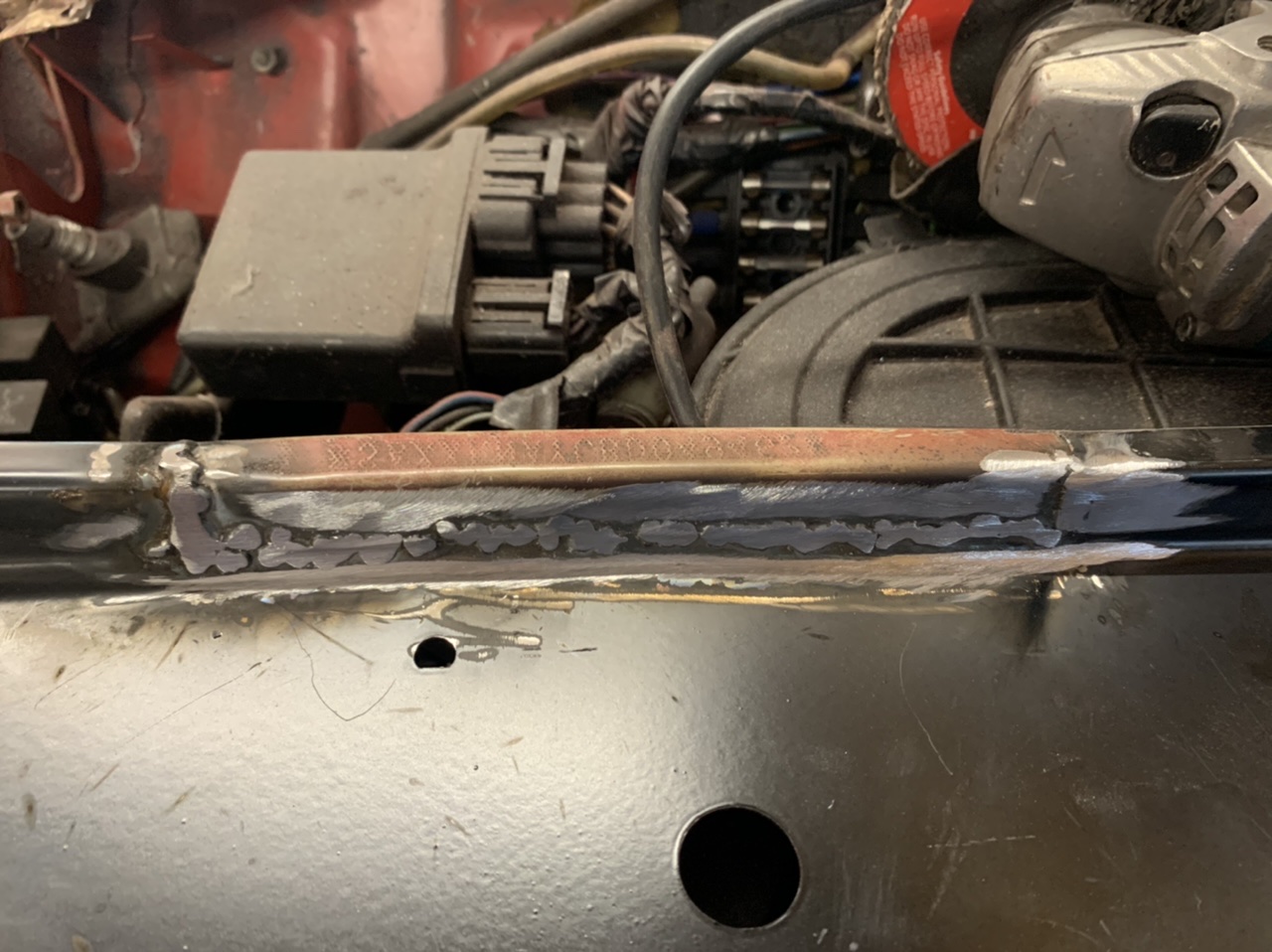

Cleaned up the corner cant tail and the inside of the inner A pillar before giving it a coat of Q Rust, etch primer then Rustoleum before concentrating on letting in hthe corner repair this morning.

Gonna leave the A pillar weld and windscreen seam until I repair the door frame/A pillar.

Not perfect as there’s a dip forward of the weld but a little body filler will put it right. Don’t have an issue with filler providing it’s not hiding holes and rust!

Gonna leave the A pillar weld and windscreen seam until I repair the door frame/A pillar.

Not perfect as there’s a dip forward of the weld but a little body filler will put it right. Don’t have an issue with filler providing it’s not hiding holes and rust!

RWD3M

Forum Supporter

- Messages

- 3,913

- Location

- Wiltshire, UK

Good man!They’re coming out before anything else is done, including the dash rail and carpet, it’s ok.

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

I’m offshore until 18th with a big Minispares delivery due around 19th so fingers crossed my two weeks home should see a big step forward.

Interior out first, unpick the remains of the front panel mounts and offside A panel, a few localised repairs to the flitches and door frame before repairs around the roof and scuttle area then scuttle replacement before getting the engine back together and repair the clutch then replace the front end.

I think that lot will take me two weeks so checking out the floors and rear subframe area will be a few weeks later after my following trip. I don’t want to get too much started or it could end up like my camper which is still lying on its side after 8 years!

Interior out first, unpick the remains of the front panel mounts and offside A panel, a few localised repairs to the flitches and door frame before repairs around the roof and scuttle area then scuttle replacement before getting the engine back together and repair the clutch then replace the front end.

I think that lot will take me two weeks so checking out the floors and rear subframe area will be a few weeks later after my following trip. I don’t want to get too much started or it could end up like my camper which is still lying on its side after 8 years!

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

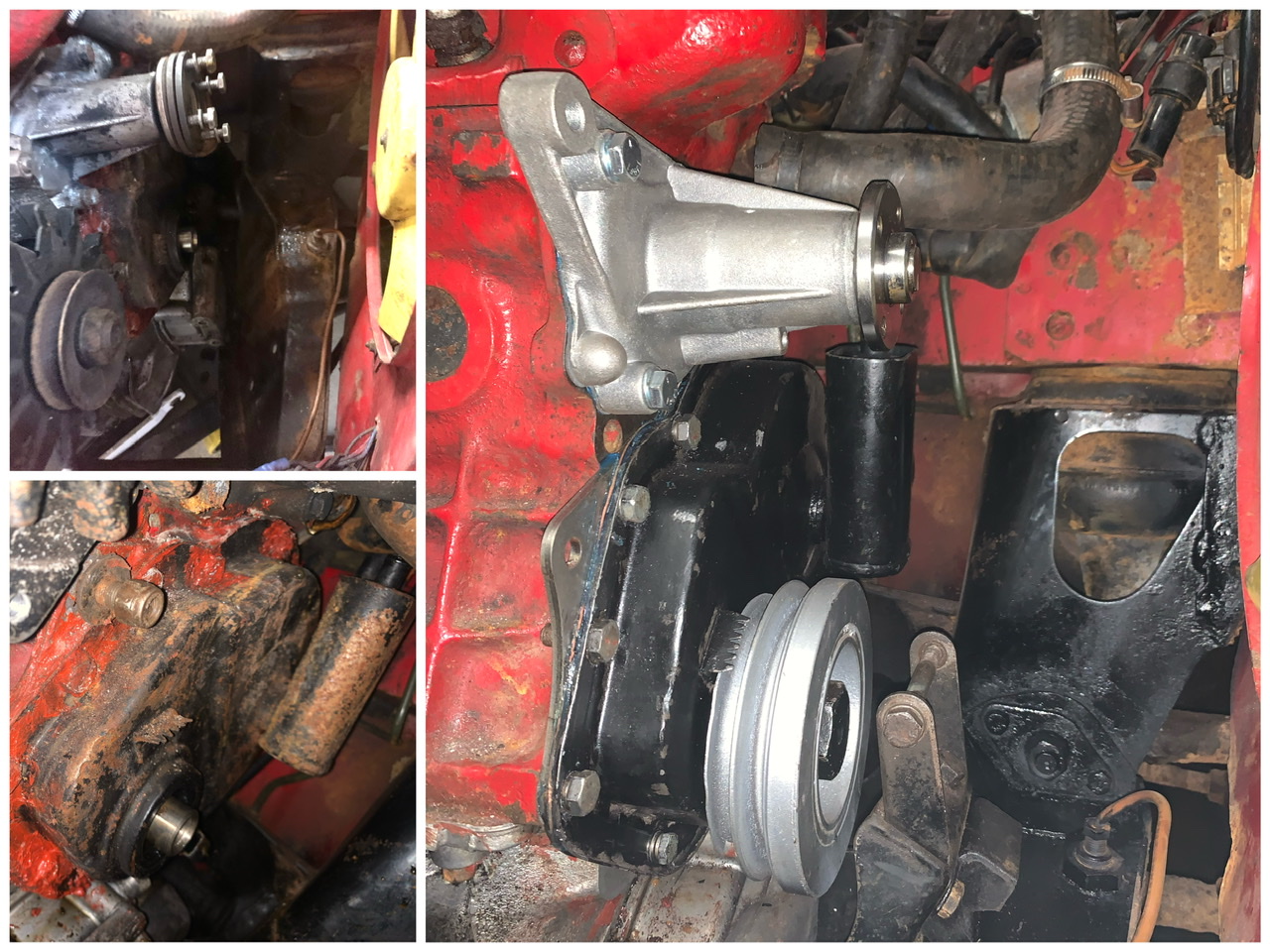

Got my parts yesterday from mini spares so made a start putting the engine back together. New front timing plate and gasket, new IWIS big pin timing chain from Keith Calver, new timing cover gasket, refurbished timing cover with new Viton lip seal and new water pump and gasket. I assembled it all then realised I’d forgotten to fit the splash washer so had to remove it all again!.

All back together with a quick change engine mount and fresh oil and filter and it starts on the button with no oil leak so far. Couldn’t run it too long as there was no water or radiator fitted. Fingers crossed that’s the oil leak taken care of.

Rad tomorrow and clutch slave and braided hose then once it drives I can continue with the bodywork.

Bit of a difference before and after!

All back together with a quick change engine mount and fresh oil and filter and it starts on the button with no oil leak so far. Couldn’t run it too long as there was no water or radiator fitted. Fingers crossed that’s the oil leak taken care of.

Rad tomorrow and clutch slave and braided hose then once it drives I can continue with the bodywork.

Bit of a difference before and after!

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

Today I decided to clean up a few components starting with the alternator which appears to be a Ford item (maybe an upgraded part?). I used a wire brush on the drill and then stuck it on the polishing mop on the bench grinder before masking the centre and end and giving it a light coat of etch primer then satin black.

Someone had sanded the top of the radiator header tank so I gave that a once over with the Solvol polish, before taking all the paint off the rad cowl, coating it with Kurust, then etch primed before satin blacking it. Then I stuck it all together and bolted it all back in. Following watching upbuildgarage videos I have purchased Fertan which seems to be similar stuff to Kurust so I’ll give it a shot once it arrives.

Already looking much better I think.

Someone had sanded the top of the radiator header tank so I gave that a once over with the Solvol polish, before taking all the paint off the rad cowl, coating it with Kurust, then etch primed before satin blacking it. Then I stuck it all together and bolted it all back in. Following watching upbuildgarage videos I have purchased Fertan which seems to be similar stuff to Kurust so I’ll give it a shot once it arrives.

Already looking much better I think.

angellonewolf

Member

- Messages

- 8,925

- Location

- bristol england

had a mini quite a few years ago loved driving it did not like the amount of work it needed on it new bearings ball joints welding seamed to be near every weekend it needed more work than ihad time in the day

but driving you seamed like you where doing 90 when if fact you where only doing the speed limit

but driving you seamed like you where doing 90 when if fact you where only doing the speed limit

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

Haha. In fairness being a fuel injected car things like points Ignition and carbs are taken care of with the ECU so some of the reliability issue of older minis are out of the equation. That’s my logic of changing things like the timing chain and water pump whilst I am in there, it’ll remove the silly usual failure issue. There’s a new clutch slave sitting here with a Goodridge braided hose and I’m waiting on silicone hoses so if I can remove a lot of the silly things which cause problems then it should be smooth ownership.

angellonewolf

Member

- Messages

- 8,925

- Location

- bristol england

Haha. In fairness being a fuel injected car things like points Ignition and carbs are taken care of with the ECU so some of the reliability issue of older minis are out of the equation. That’s my logic of changing things like the timing chain and water pump whilst I am in there, it’ll remove the silly usual failure issue. There’s a new clutch slave sitting here with a Goodridge braided hose and I’m waiting on silicone hoses so if I can remove a lot of the silly things which cause problems then it should be smooth ownership.

most of the problems i seen omn mine where not engine stuff its running gear bushes ball joints bearings

think mine had been in the wars before i got it mind

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

Following with interest. Minis are great fun, I confess to having [a van no less, but slightly breathed on  and latterly used in Club rallies, I did have an RAC comp licence back in the day i.e young and a bit foolish

and latterly used in Club rallies, I did have an RAC comp licence back in the day i.e young and a bit foolish  ] all four wheels in the air over a humpback bridge - not that I'd recommend that for a second.

] all four wheels in the air over a humpback bridge - not that I'd recommend that for a second.

A pal in the back complained that "things are jumping about back here" - that'd be the toolbox, then.....

A pal in the back complained that "things are jumping about back here" - that'd be the toolbox, then.....

I think that's what did for the front suspension which my Dad and I managed to strip down he having made the necessary bits for us to be able dismantle & fix at his work - I didn't confess....obviously!

A pal in the back complained that "things are jumping about back here" - that'd be the toolbox, then.....

A pal in the back complained that "things are jumping about back here" - that'd be the toolbox, then.....

I think that's what did for the front suspension which my Dad and I managed to strip down he having made the necessary bits for us to be able dismantle & fix at his work - I didn't confess....obviously!

- Messages

- 23,915

- Location

- Birmingham

Following with interest. Minis are great fun, I confess to having [a van no less, but slightly breathed onand latterly used in Club rallies, I did have an RAC comp licence back in the day i.e young and a bit foolish

] all four wheels in the air over a humpback bridge - not that I'd recommend that for a second.

A pal in the back complained that "things are jumping about back here" - that'd be the toolbox, then.....

I think that's what did for the front suspension which my Dad and I managed to strip down he having made the necessary bits for us to be able dismantle & fix at his work - I didn't confess....obviously!

I did that on a night rally, blew the seals on both front dampers, I worked at Longbridge at the time so a word to the right person and I had a new pair of dampers about 30 minutes later

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

Today I couldn’t be bothered to go up the man cave then decided I had an hour spare later so went up to at least do something. As I’m replacing the scuttle panel I thought I’d remove the vin number from the original scuttle and let it into the new one. Not technically ringing the vehicle  but something usually left out by most people. I just wanted it right when it’s complete. Took me a little while tweaking the power and wire feed but going forward it should be pretty close.

but something usually left out by most people. I just wanted it right when it’s complete. Took me a little while tweaking the power and wire feed but going forward it should be pretty close.

but something usually left out by most people. I just wanted it right when it’s complete. Took me a little while tweaking the power and wire feed but going forward it should be pretty close.

but something usually left out by most people. I just wanted it right when it’s complete. Took me a little while tweaking the power and wire feed but going forward it should be pretty close.

Last edited:

Oooo, now I wouldn't have done this. I may have welded the original,bit on somewhere, but it looks too much like a ringed job the way you've done it. Some thick copper might take that the wrong way, and you'd have to prove you had to replace the scuttle - keep the pics.

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

I don’t think so somehow!

Once I’ve finished you will not see it’s been welded in. The reason it wasn’t finished was we were leaving to go out. Once I’m back up the garage I’ll post pics. That said my phone has thousands of pics on it and is always with me. Either way I don’t think it’ll be an issue.

Once I’ve finished you will not see it’s been welded in. The reason it wasn’t finished was we were leaving to go out. Once I’m back up the garage I’ll post pics. That said my phone has thousands of pics on it and is always with me. Either way I don’t think it’ll be an issue.