You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drilling out broken diesel injector from Cylinder head BMW M57

- Thread starter Franknstein

- Start date

yes ,,, and that speaks volumes , lolAm I the only one which would be ballsy with a blow torch to try and get some heat into it?

May even go rude and tap a thread where the injector nozzle goes to get a bolt in there and then fill with proper carbon cleaner.

yes ,,, and that speaks volumes , lol

Ruffian by name

Ruffian by nature.

But then again do remember a partner 1.6hdi which had a new glow plug for cylinder 1 slid inside a piece of pipe until the original snapped bit fired out. That was 2 weeks later along the a30.

And the amount of vivaro injectors snapped.

Got to love modern engines.

There’s a guy down our way has the kit to bolt the boring machine to Renault /vivaro engines to drill these out in situ. I would guess the beemer is similar, but would need it’s own jigs..Ruffian by name

Ruffian by nature.

But then again do remember a partner 1.6hdi which had a new glow plug for cylinder 1 slid inside a piece of pipe until the original snapped bit fired out. That was 2 weeks later along the a30.

And the amount of vivaro injectors snapped.

Got to love modern engines.

theres a guy over here does glow plugs ,,, cant remember the price but hes dear , and expects paid whether they come out or not ,,,, ive not yet got to watch him ,,, but I will at some point.There’s a guy down our way has the kit to bolt the boring machine to Renault /vivaro engines to drill these out in situ. I would guess the beemer is similar, but would need it’s own jigs..

For me, it'd be buying the right tool (injector extractor) or tapping the sleeve out, suitable bolt fitted and slide hammering the rest out.

Trying to get heat into the head is hard work on Aluminium.

In hindsight you should have got the car stinking hot first before pulling the injectors.

I've seen cars lifted off the floor by the injectors they were that seized in!.

Bear in mind any tool that expands will likely push the injector end tighter into the head, tap and bolt will not add any increased interference fit.

Good luck!.

Trying to get heat into the head is hard work on Aluminium.

In hindsight you should have got the car stinking hot first before pulling the injectors.

I've seen cars lifted off the floor by the injectors they were that seized in!.

Bear in mind any tool that expands will likely push the injector end tighter into the head, tap and bolt will not add any increased interference fit.

Good luck!.

zeppelin builder

Member

- Messages

- 2,133

- Location

- peoples republic of scotland

how about stick welding a length of all thread to the remains then put a big washer over the hole and pull it out with the nut .

you can bend the rutile electrode 6013 a bit

you can bend the rutile electrode 6013 a bit

Franknstein

New Member

- Messages

- 29

- Location

- Milton Keynes, UK

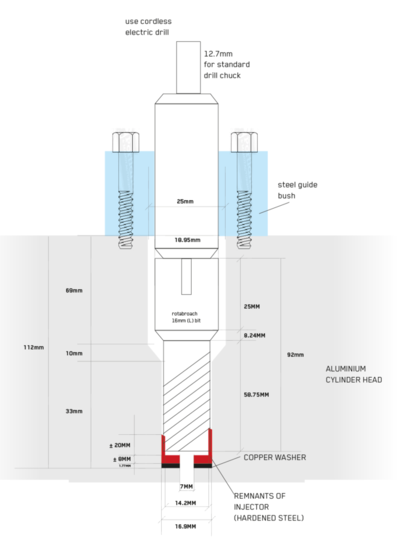

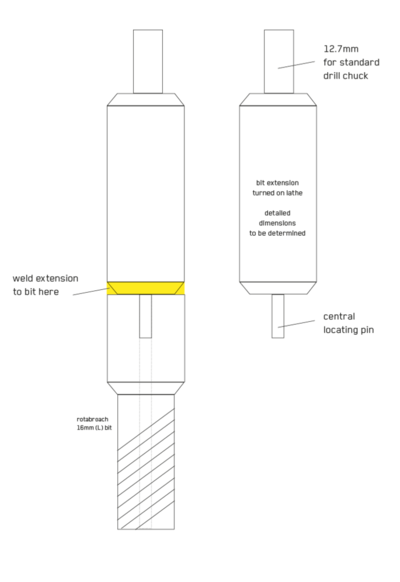

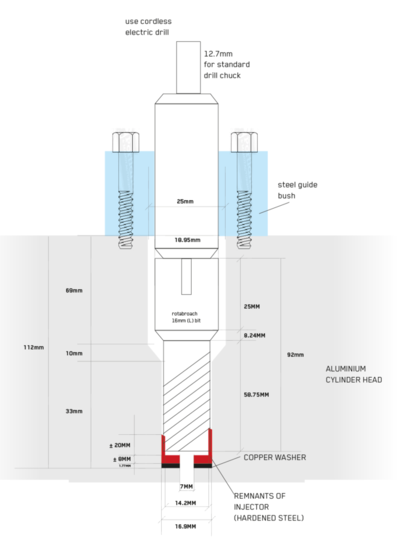

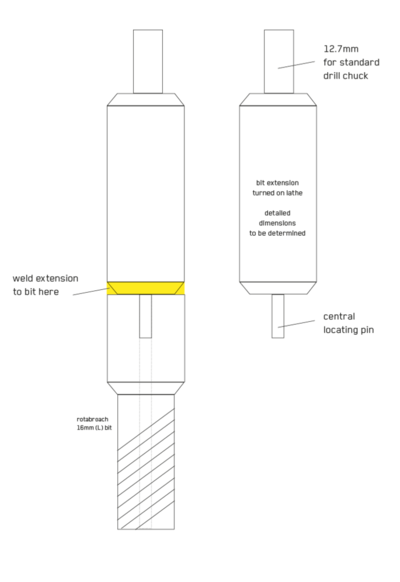

Thanks everyone for your valued input. Some great ideas here. I've updated some drawings which I'll attach below. My thoughts from some of the input here from @Kram and @James1979.

See what you think. Mag drill may be better but then would have to make the top end of the extension compatible with the ?Weldon? chuck? If I had a larger guide bush I don't see why a hand drill would not work...

See what you think. Mag drill may be better but then would have to make the top end of the extension compatible with the ?Weldon? chuck? If I had a larger guide bush I don't see why a hand drill would not work...

Haven't you got it out yet?Thanks everyone for your valued input. Some great ideas here. I've updated some drawings which I'll attach below. My thoughts from some of the input here from @Kram and @James1979.

See what you think. Mag drill may be better but then would have to make the top end of the extension compatible with the ?Weldon? chuck? If I had a larger guide bush I don't see why a hand drill would not work...

View attachment 367655 View attachment 367656

Tap an M8 thread into that hole (close enough). long bolt pull against a washer (as zepplin said). but beware that will leave debris in the chamber.

i would be using a use a drill as a last resort.

Kram

Member

- Messages

- 8,527

- Location

- Sussex

HSS is not going to like being welded to extension. It can be brazed with no issue, Silverflo 55 would keep the temperature well below softening the edge.

With either joining it will bend, needing to be finish turned true to the drill after heating - you'd have to send me the cutter.

If the smaller mini cutters have enough cutting depth (6.4mm is listed for the rotabroach ones) that would be simpler, depending what thread they use, probably an obscure UNF/UNC size.

With either joining it will bend, needing to be finish turned true to the drill after heating - you'd have to send me the cutter.

If the smaller mini cutters have enough cutting depth (6.4mm is listed for the rotabroach ones) that would be simpler, depending what thread they use, probably an obscure UNF/UNC size.

Just an idle thought but what's to stop you trying to cut a M15 thread in the bit of injector that's stuck in there?

According to your Drg the stuck bits got an internal diameter of 14.2 mm which is about the tapping size. If you can get a tap started and cut a thread all the way down you might still be able to pull it out without drilling?

Got to be less risky than the drilling lark, and you never know, if you can get the tap started the twisting force might even break it free?

According to your Drg the stuck bits got an internal diameter of 14.2 mm which is about the tapping size. If you can get a tap started and cut a thread all the way down you might still be able to pull it out without drilling?

Got to be less risky than the drilling lark, and you never know, if you can get the tap started the twisting force might even break it free?

even better if it had been soaking in injectorex ,,,Just an idle thought but what's to stop you trying to cut a M15 thread in the bit of injector that's stuck in there?

According to your Drg the stuck bits got an internal diameter of 14.2 mm which is about the tapping size. If you can get a tap started and cut a thread all the way down you might still be able to pull it out without drilling?

Got to be less risky than the drilling lark, and you never know, if you can get the tap started the twisting force might even break it free?

arther dailey

Member

- Messages

- 7,006

- Location

- England

more details please how you went about this ,thanksI took a broken injector out of a head.

The injector was well stuck and the thread snapped off it.

It was taken to an "expert", who snapped a milling cutter in it.

I set about it with battery acid and a battery charger.

It removed the cutter and injector leaving the hole clean and lightly anodised.

graffian

Seer unto the end of his beard

- Messages

- 3,829

- Location

- gatwick

It's basically anodising?more details please how you went about this ,thanks

Bit of ali tube clamped to the head to form an acid reservoir.

Head is cathode.

Bit of ali welding rod as anode. Bulb in series so shorts don't matter. Wire movable so you can set it close to the injector.

Battery acid and battery charger.

Acid becomes manky and needs cleaning out and replacing every few hours.

My acid reservoir is ~30cc and that is an OK amount for the few hours I have it on in the afternoons.

I mentioned tapping it further up the thread as well.Just an idle thought but what's to stop you trying to cut a M15 thread in the bit of injector that's stuck in there?

According to your Drg the stuck bits got an internal diameter of 14.2 mm which is about the tapping size. If you can get a tap started and cut a thread all the way down you might still be able to pull it out without drilling?

Got to be less risky than the drilling lark, and you never know, if you can get the tap started the twisting force might even break it free?

Kram

Member

- Messages

- 8,527

- Location

- Sussex

The problem with electrolysis, its not a sealed container and you cant easily seal it up while allowing the part to be eaten.

Wrong way around, the anode/positive is eaten, cathode/negative grows with whatever metal is in solution. If the part to be eaten is stuck in the head that will be the anode and the cathode is the submerged wire. Use 12-20v, the steel should be eaten first. Using a bulb in series will make it very slow, a cheap buck/boost converter will give lots of control over itHead is cathode.

Bit of ali welding rod as anode.

If the head gasket, bolts, new injector etc had been ordered Friday from local factors . . . head off saturday morning . . . abuse with punched, chisels, hammers, blowtorches, extractors etc saturday afternoon, into sunday . . . pick up gaskets monday lunchtime . . . drop head off for skim . . . if lucky like my local, hang around while done . . . head back on by Monday evening . . . celebratory blast around block this morning . . . ?

Or am I lucky to drive a Lancia, or a Dodge, where parts arrive within 24hrs?

(well, okay, 72 hrs from Arizona in the case of the Dodge)

I learnt a long time ago, the chances of a bigger cock-up (and therefore more unnecessary expense and wasted time - something I'm allergic to) when trying short cuts, bodge jobs etc tend to get quite high . . .

Or am I lucky to drive a Lancia, or a Dodge, where parts arrive within 24hrs?

(well, okay, 72 hrs from Arizona in the case of the Dodge)

I learnt a long time ago, the chances of a bigger cock-up (and therefore more unnecessary expense and wasted time - something I'm allergic to) when trying short cuts, bodge jobs etc tend to get quite high . . .