Dcal

Member

- Messages

- 4,094

- Location

- Antrim Northern Ireland

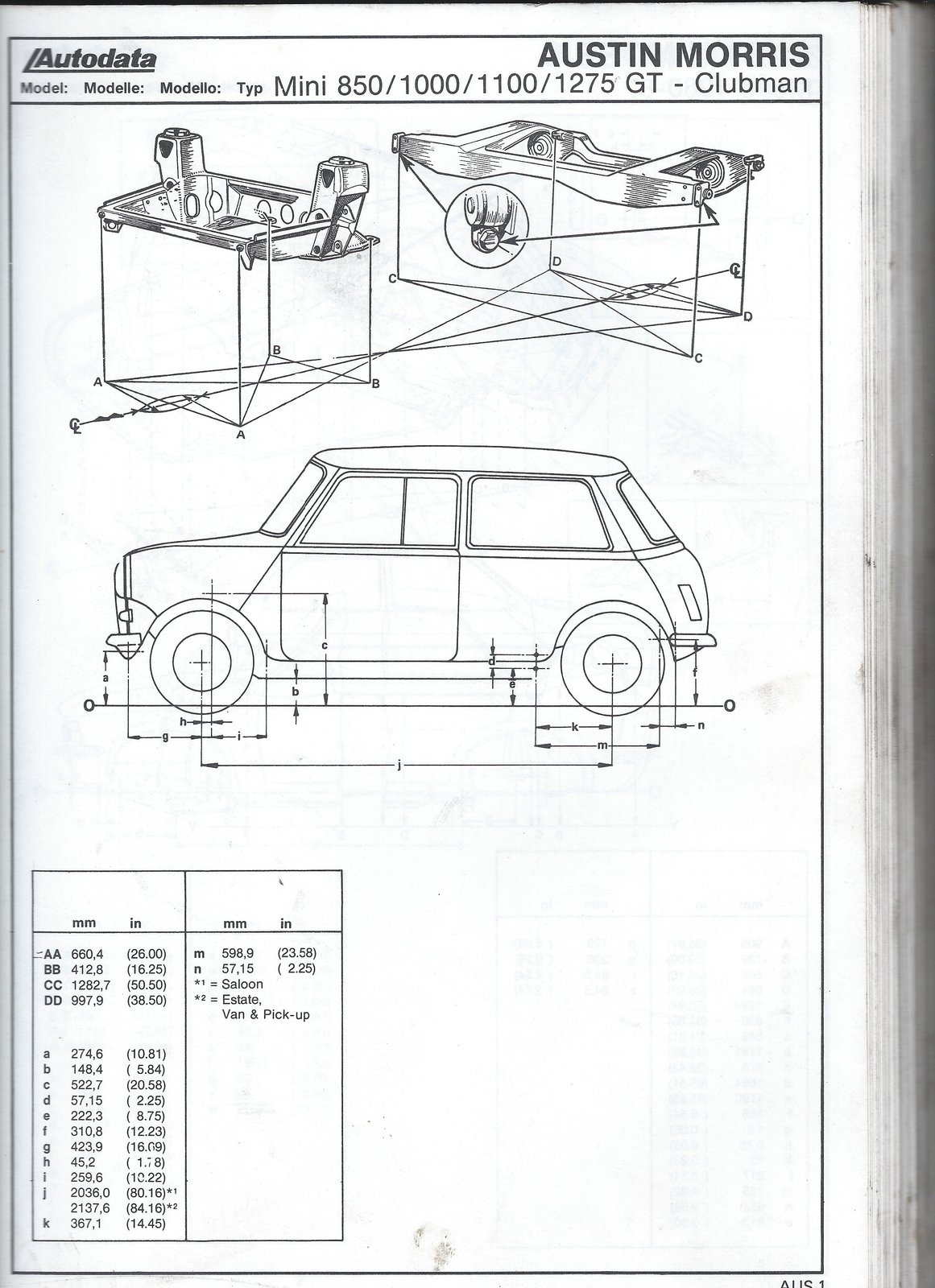

Not sure if this is any use to you but this scan shows the main suspension measurements.

I know it's not much use for body measurements, but you can be a bit more approximate with the bodywork dimensions as the cars from that ere were all pretty much hand built, not by choice but because that was where the technology had got to.

These are the measurements that matter to get the car handling and tracking properly.

I know it's not much use for body measurements, but you can be a bit more approximate with the bodywork dimensions as the cars from that ere were all pretty much hand built, not by choice but because that was where the technology had got to.

These are the measurements that matter to get the car handling and tracking properly.