Agroshield

Member

- Messages

- 6,260

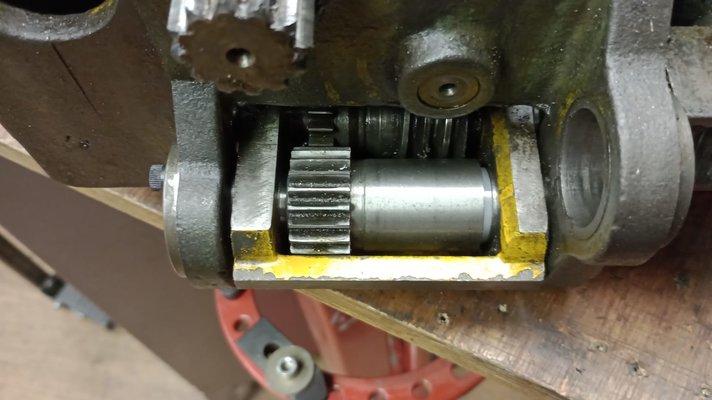

...a key that followed the spline, but I cannot see anything, and the inside is smooth so how do they lock together to rotate?

The apron on a Bantam is the same as on a Chipmaster, so that will provide another avenue where you might find a solution.

Have you dismantled the apron and removed part A? If not yet, be very careful dismantling the shaft behind it, the one with the worm on it. It is preloaded with springs and the tension on the springs sets the automatic feed knock off. If you make the springs too tight, the feed knock off will not work properly. It might push the bedstop along the bed resulting in a crash or spoiled part. It might shear the shear pin further up in the drive train. So when reassembling it, err on the side of making the preload too little. If the auto trip trips too early, you can always tighten it up a little.

Anyway, yes there should be something to transmit the drive. Clean the part very well and you might see how it is constructed*. The drive key or drive pin is unlikely to be made integral with the part as that makes it very difficult (and expensive) to manufacture. So, if it is a pin, you will see the hole through which it is inserted from the outside. If it is a key, you will see the keyway at one end or the other of the part.

If you cannot find it, drill a hole and loctite in a pin the correct diameter to go in the keyway in the leadscrew.

*Spray it with brake cleaner and sometimes a damp line will appear at the join - it is a poor man's version of a die penetrant test.