Dieselman 63

Forklift Certified

- Messages

- 5,850

- Location

- Wellington, New Zealand

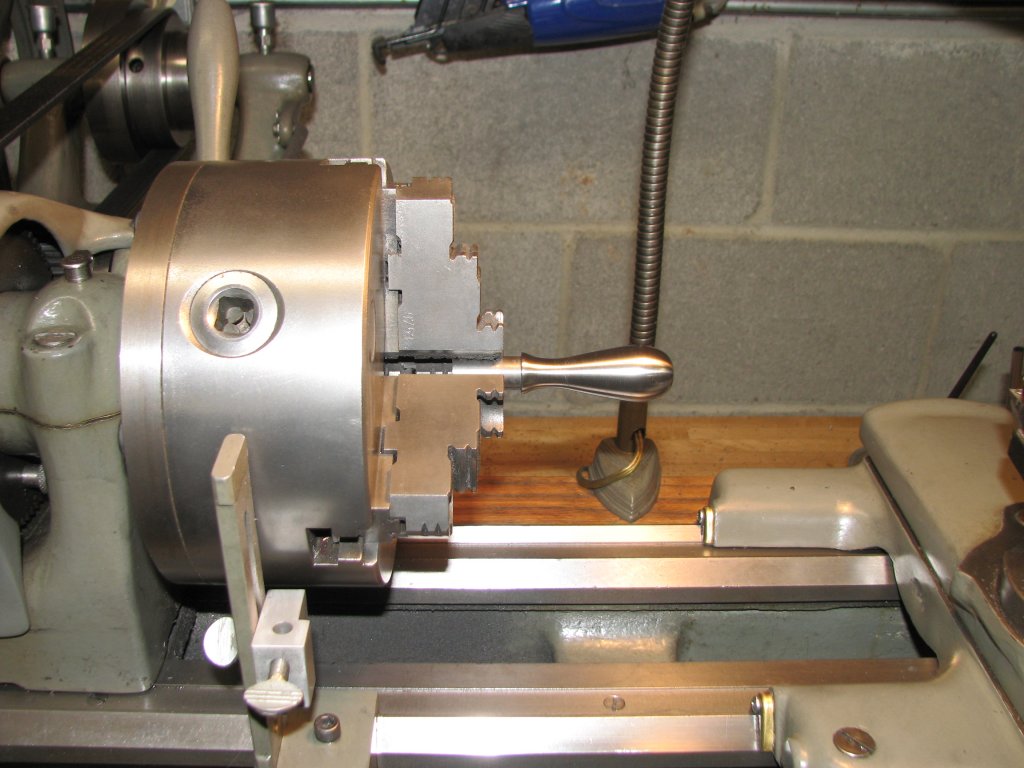

IMO a ball feels wrong (!) it would feel nicer if, when you get your lathe running, to make a teardrop shape like some other toolposts.

Got any pictures?

Edit: of teardrop handles (I don't want any miscommunication here

![IMG_0207[1].JPG IMG_0207[1].JPG](https://www.mig-welding.co.uk/forum/data/attachments/104/104193-553b65791977f06681786693030ac6e2.jpg?hash=VTtleRl38G)

Everything seems to be so damn expensive here though. One sold the other day on Trademe for $595... that's $95 more than I paid for the entire machine

Everything seems to be so damn expensive here though. One sold the other day on Trademe for $595... that's $95 more than I paid for the entire machine  Got some tool holders but they've turned out to be a bit rubbish, maybe even home cast/built up weld.

Got some tool holders but they've turned out to be a bit rubbish, maybe even home cast/built up weld.