TwoThumbs

Member

- Messages

- 121

- Location

- Finland

Nice to hear about inspiration, we all need it from time to time and I'm happy if I provided some.Yeah, Im wondering, after post winter inspection of suspension bits, if I need new sway bar bushings....I may do it anyway!...youve inspired me.

lookin good....(I did the same thing on my e-36 trailer......smoothed out the sway bar....mounts painted!....all satin black)

JP

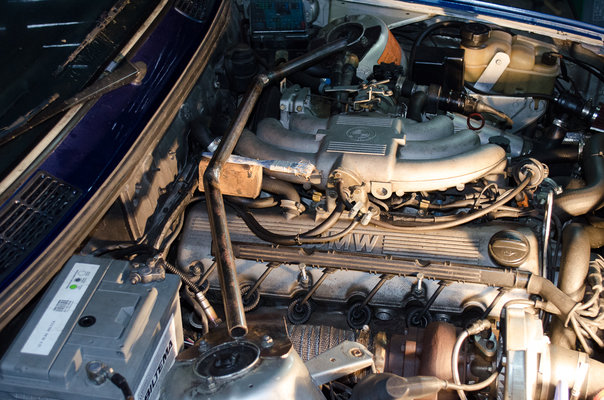

No real new updates this time only few things to report.

Car has been on the road for few days. Problems with binding front anti-roll bar seems to been resolved. Cornering has improved and is now consistent, before car was cornering one way or the other way and sometimes felt that it changed mind during the corner, it just felt wrong to me. Speaking of mounting bushes went in and ordered set of Powerflex bushings for anti-roll bars to replace tired rubber ones and will possibly report later how they feel.

Rear end LSD seems to hook well, one tire on pavement and one on gravel it will spin both tires leaving rubber stripe on pavement, can't really hope much more than that.

Biggest surprise for the driving season has been my ported turbocharger. It still boost same amount, no significant changes to air/fuel ratios of exhaust gasses but car feels different faster and more agressive. Only change that I found from data log compared to last summer was that maximum boost spike is now coming at least 200-300 RPM earlier than it did before exhaust porting. It feels that it made significant difference on how it delivers power and now it seems to be hitting boost like animal. Real impressed from small grinding job.

That's all this time and hope everyone is doing well there!