TwoThumbs

Member

- Messages

- 121

- Location

- Finland

Back on E30!

After being few months in shed for winter storage you can always expect some minor technical issues.

Clutch had stopped working and pedal went to the floor. Brake fluid seemed to be on a low side, didn't found any obvious leaks but I made assumption that clutch slave cylinder might have been leaking.

Instead of replacing complete clutch slave cylinder I opted for more hobbyist solution and went for cheap rebuild kit.

Original slave cylinder and what came in a rebuild kit:

Disassembled clutch slave cylinder was in rebuildable condition. Honed insides of cylinder with scotch brite pad and put it back together with new seals.

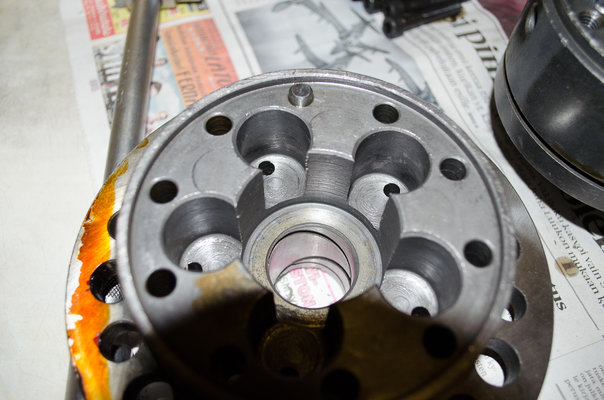

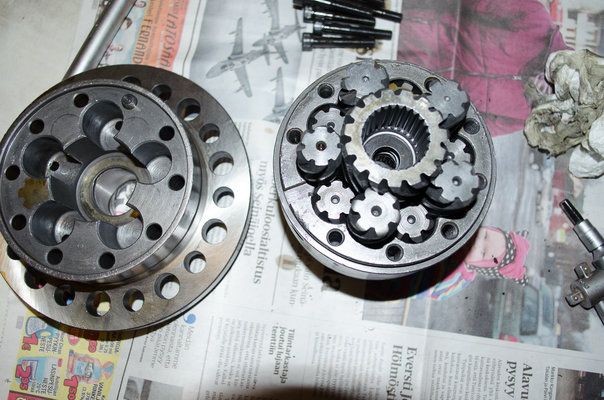

Power steering has been leaky and making some puddles. Got power steering pump seal kit from BMW dealer and followed some Youtube guide for Porsche ZF power steering pump seal installation for instructions.

Old shaft seal was like hard plastic and was difficult to get it out, no wonder why the pump was leaking.

Power steering pump and new seals:

Went shopping for new anti-roll bar links, even when old ones were still in decent condition new ones might provide marginally improved stability and cornering capabilities.

Went for Meyle HD front links, they seemed really sturdy but never know how they will last:

While doing front anti-roll bar links spotted another problem. Roll bar should be movable by hand after disconnecting the end links but mine was fused solid with chassis bushings and needed pry bar to move it, not good.

Removed roll bar bushes from the chassis, cleaned them and bar with brake cleaner.

Rubber bush was dirty and probably sticky from all kind of chemicals. Minor pitting was found from the bar as well so I may need to return to this issue with more serious bar restoration activity, but for now just cleaning everything seemed to help and got the bar moving much more easily.

Sticky anti-roll bar bushing:

Then on the rear end. Rear anti-roll bar mounting tabs are weak on E30 and can fracture off from the trailing arm. Mines were still fine but found that i could flex these tabs fairly easily. I wanted to fabricate and weld something so made some DIY reinforcements and welded them in to the car.

Original mounting tabs:

Fabricated reinforcement plate from 3 mm flat steel to something like this:

Attacked welding job with 0.8 mm wire on a mig and this is how it turned out:

Reinforced non flexing anti-roll bar mounting tab after painting and ready to be finished with brushing some stonechip for extra corrosion protection:

This was all for now!

Thanks for viewing!

After being few months in shed for winter storage you can always expect some minor technical issues.

Clutch had stopped working and pedal went to the floor. Brake fluid seemed to be on a low side, didn't found any obvious leaks but I made assumption that clutch slave cylinder might have been leaking.

Instead of replacing complete clutch slave cylinder I opted for more hobbyist solution and went for cheap rebuild kit.

Original slave cylinder and what came in a rebuild kit:

Disassembled clutch slave cylinder was in rebuildable condition. Honed insides of cylinder with scotch brite pad and put it back together with new seals.

Power steering has been leaky and making some puddles. Got power steering pump seal kit from BMW dealer and followed some Youtube guide for Porsche ZF power steering pump seal installation for instructions.

Old shaft seal was like hard plastic and was difficult to get it out, no wonder why the pump was leaking.

Power steering pump and new seals:

Went shopping for new anti-roll bar links, even when old ones were still in decent condition new ones might provide marginally improved stability and cornering capabilities.

Went for Meyle HD front links, they seemed really sturdy but never know how they will last:

While doing front anti-roll bar links spotted another problem. Roll bar should be movable by hand after disconnecting the end links but mine was fused solid with chassis bushings and needed pry bar to move it, not good.

Removed roll bar bushes from the chassis, cleaned them and bar with brake cleaner.

Rubber bush was dirty and probably sticky from all kind of chemicals. Minor pitting was found from the bar as well so I may need to return to this issue with more serious bar restoration activity, but for now just cleaning everything seemed to help and got the bar moving much more easily.

Sticky anti-roll bar bushing:

Then on the rear end. Rear anti-roll bar mounting tabs are weak on E30 and can fracture off from the trailing arm. Mines were still fine but found that i could flex these tabs fairly easily. I wanted to fabricate and weld something so made some DIY reinforcements and welded them in to the car.

Original mounting tabs:

Fabricated reinforcement plate from 3 mm flat steel to something like this:

Attacked welding job with 0.8 mm wire on a mig and this is how it turned out:

Reinforced non flexing anti-roll bar mounting tab after painting and ready to be finished with brushing some stonechip for extra corrosion protection:

This was all for now!

Thanks for viewing!