Hi,

My TIG welder is a Parweld XTT 202P. I'm completely new to TIG but have been arc welding for the last 55 years. I finally gathered all the kit and materials so this afternoon I was keen to finally have a go.

I was trying to weld 1mm thick aluminium as a lap joint and tried various amps; I don't have a foot pedal but after a few attempts started to make progress at 40A then suddenly a loud bang followed by a dense cloud of smoke.

The welder is brand new but sold to me by the buyer who had stored it under his bench for about a year; the warranty isn't transferrable. I came up to the bungalow to allow the smoke cloud to disperse whilst I enjoyed a mug of tea.

Having now checked and found it wasn't covered by warranty I had nothing to lose; I've stripped the welder pulling out a circuit board containing a bank of 6 capacitors; Jianghai CD294 200V 1200uF two of these had expired big style; I'm now trying to locate capacitors of the same physical dimensions; I can easily buy the 200V 1200uF via eBay. I restored vintage valve radios for ten years so changing a couple of caps isn't going to upsert me; normally I'd just upgrade the voltage but given the many electronics on this machine I'll stick to original spec.

I'm just posting this for interest because I'm used to such problems; I wondered if any other member had suffered such a problem; as I say I'm new to TIG welding but I expected the machine to be idiot proof which it obviously isn't.

Yesterday I bought a new Optrel Crystal 2.0 helmet and at least this is absolutely brilliant as the Americans would say it's awesome.

Kind regards, Colin.

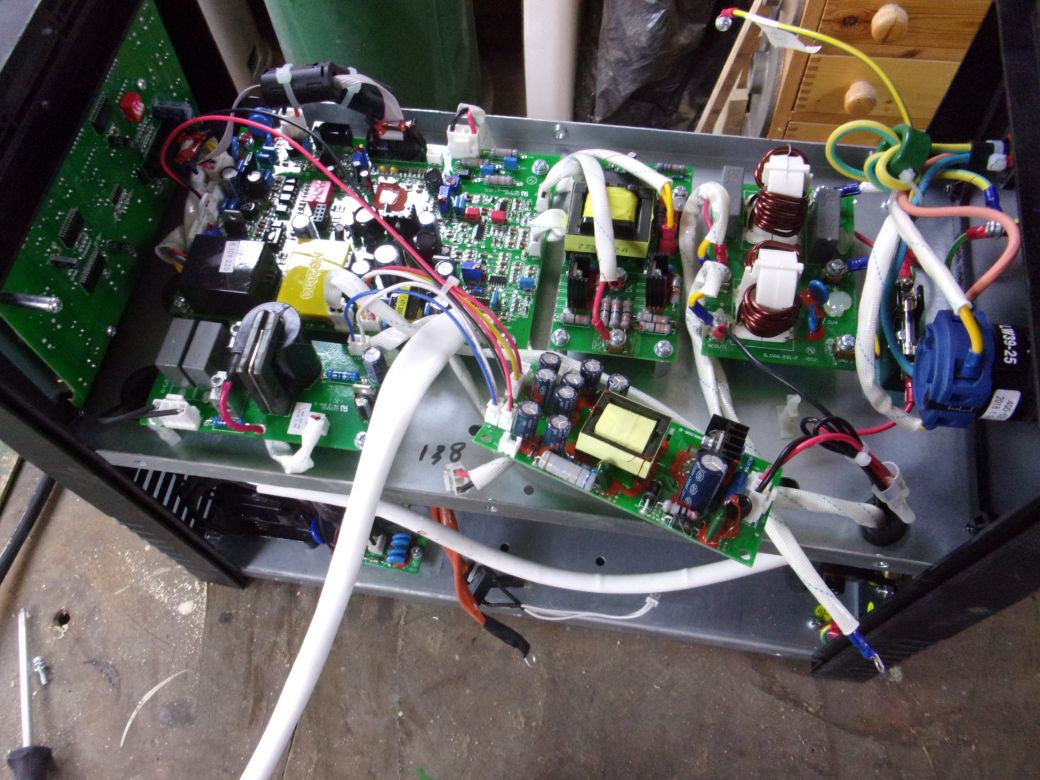

Two blown caps; easy job to replace them but more difficult to remove the circuit board.

A smaller circuit board had to be removed to gain access to one of the mounting screws. I took a lot of care not to touch any of the component connections because I'm well aware of static problems.

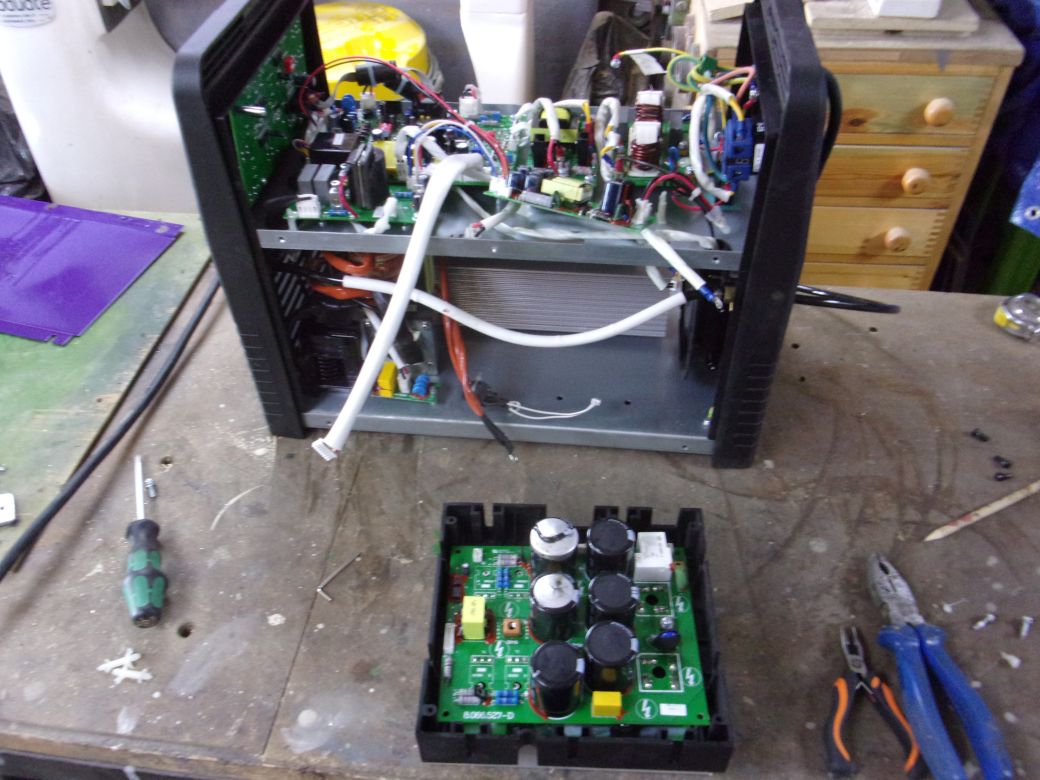

The circuit board out ready for the caps to be replaced. This is most unexpected.

My TIG welder is a Parweld XTT 202P. I'm completely new to TIG but have been arc welding for the last 55 years. I finally gathered all the kit and materials so this afternoon I was keen to finally have a go.

I was trying to weld 1mm thick aluminium as a lap joint and tried various amps; I don't have a foot pedal but after a few attempts started to make progress at 40A then suddenly a loud bang followed by a dense cloud of smoke.

The welder is brand new but sold to me by the buyer who had stored it under his bench for about a year; the warranty isn't transferrable. I came up to the bungalow to allow the smoke cloud to disperse whilst I enjoyed a mug of tea.

Having now checked and found it wasn't covered by warranty I had nothing to lose; I've stripped the welder pulling out a circuit board containing a bank of 6 capacitors; Jianghai CD294 200V 1200uF two of these had expired big style; I'm now trying to locate capacitors of the same physical dimensions; I can easily buy the 200V 1200uF via eBay. I restored vintage valve radios for ten years so changing a couple of caps isn't going to upsert me; normally I'd just upgrade the voltage but given the many electronics on this machine I'll stick to original spec.

I'm just posting this for interest because I'm used to such problems; I wondered if any other member had suffered such a problem; as I say I'm new to TIG welding but I expected the machine to be idiot proof which it obviously isn't.

Yesterday I bought a new Optrel Crystal 2.0 helmet and at least this is absolutely brilliant as the Americans would say it's awesome.

Kind regards, Colin.

Two blown caps; easy job to replace them but more difficult to remove the circuit board.

A smaller circuit board had to be removed to gain access to one of the mounting screws. I took a lot of care not to touch any of the component connections because I'm well aware of static problems.

The circuit board out ready for the caps to be replaced. This is most unexpected.