Richard.

Member

- Messages

- 18,344

- Location

- Cambridgeshire

As has been requested by a small number of members I'm happy to start a small guide as a starting point for newcomers into welding aluminium. The idea is to simply give you a starting point so your new toy can be taken from the box and dialed in without the grief of guess work or diving through countless threads with lots of compromising opinions and info.

There are literally thousands of combinations as to what can be done to weld it I'm just going to talk about the meer basics and after that it's up to you.

I'll do it over time and generate a few posts and get some pics in it to help illustrate.

Alu tig is welded in AC and

You require an AC DC tig machine to do this.

AC is a fluctuation on polarity which can confuse because the output is always DC but the fluctuation is between DC+ and DC- . This is the noise you here when you strike it up. Now all tig welding requires the torch lead to be connected into the negative terminal so that the heat concentration is in the work piece and AC is no different except the current also passes into the positive side too.

The reason. Alu has a thin oxide layer that will self regenerate and is never completely removed. The spike from the current passing into the positive polarity allows this oxide layer to be moved out of the way so that the bear Alu under is exposed for welding. This is the reason why it is known as "cleaning(DC+)" and "penitration(DC-)"

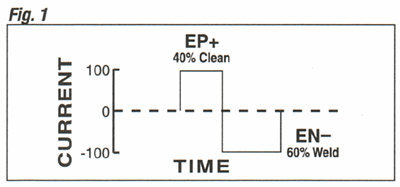

Now this information is best understood in the form of a wave. It has nothing to do with pulse welding despite a wave used to illustrate that too as it isn't a variation on current but a variation on time spent in a polarity.

What can we do to that wave?

Well modern machines allow us to do just about anything to it including even changing its shape but from a beginning point of view there is usually 2 key things we can do to it.

1) balance. Can be also known as cleaning on some machines.

This allows you to set where you want the polarity biased.

2) frequency (again no link to pulse) it's AC frequency and this allows you to set the amount of times that fluctuation happens over a period of time and is usually set in Hz/second. So 1 full hz is a cycle of up in the positive and down in the negative.

This is all for now. Lots of info here so far which is an introduction to what it is and why we use it. I'll update further on it soon.

There are literally thousands of combinations as to what can be done to weld it I'm just going to talk about the meer basics and after that it's up to you.

I'll do it over time and generate a few posts and get some pics in it to help illustrate.

Alu tig is welded in AC and

You require an AC DC tig machine to do this.

AC is a fluctuation on polarity which can confuse because the output is always DC but the fluctuation is between DC+ and DC- . This is the noise you here when you strike it up. Now all tig welding requires the torch lead to be connected into the negative terminal so that the heat concentration is in the work piece and AC is no different except the current also passes into the positive side too.

The reason. Alu has a thin oxide layer that will self regenerate and is never completely removed. The spike from the current passing into the positive polarity allows this oxide layer to be moved out of the way so that the bear Alu under is exposed for welding. This is the reason why it is known as "cleaning(DC+)" and "penitration(DC-)"

Now this information is best understood in the form of a wave. It has nothing to do with pulse welding despite a wave used to illustrate that too as it isn't a variation on current but a variation on time spent in a polarity.

What can we do to that wave?

Well modern machines allow us to do just about anything to it including even changing its shape but from a beginning point of view there is usually 2 key things we can do to it.

1) balance. Can be also known as cleaning on some machines.

This allows you to set where you want the polarity biased.

2) frequency (again no link to pulse) it's AC frequency and this allows you to set the amount of times that fluctuation happens over a period of time and is usually set in Hz/second. So 1 full hz is a cycle of up in the positive and down in the negative.

This is all for now. Lots of info here so far which is an introduction to what it is and why we use it. I'll update further on it soon.