jpmillermatic

Member

- Messages

- 1,094

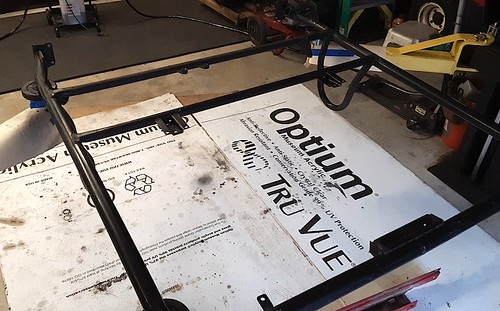

With the new battery all charged and ready to go, it was time to get the battery tray area ready. It had deteriorated pretty badly over the years from battery acid spills and being exposed to the elements, ect.

Here is the area in question: There was no battery tray left at all.....

The new battery got a custom made tray from galvanized sheet. I gave the end walls double thickness as I wanted a mounting flange built in along the bottom. (no welding or fasteners challenge)

Even the thick steel from the leading edge piece along the door opening was pretty compromised on one end and a section had to be replaced.

First, cut out the affected area. If I have learned anything, its to cut back to clean metal.

Then find some donor metal to let in. I knew I had some thicker stuff down in the shed...

I cut it out with a grinder, then cleaned it up and clamped it in place

I welded up both sides

and dressed it back

then I cut a piece for the floor area. Getting the bolts out from the cab unit proved difficult, and I ran out of time and energy.....so until tomorrow.....

thanks for lookin!

JP

Here is the area in question: There was no battery tray left at all.....

The new battery got a custom made tray from galvanized sheet. I gave the end walls double thickness as I wanted a mounting flange built in along the bottom. (no welding or fasteners challenge)

Even the thick steel from the leading edge piece along the door opening was pretty compromised on one end and a section had to be replaced.

First, cut out the affected area. If I have learned anything, its to cut back to clean metal.

Then find some donor metal to let in. I knew I had some thicker stuff down in the shed...

I cut it out with a grinder, then cleaned it up and clamped it in place

I welded up both sides

and dressed it back

then I cut a piece for the floor area. Getting the bolts out from the cab unit proved difficult, and I ran out of time and energy.....so until tomorrow.....

thanks for lookin!

JP