You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

my mk5 cortina estate

- Thread starter ian f

- Start date

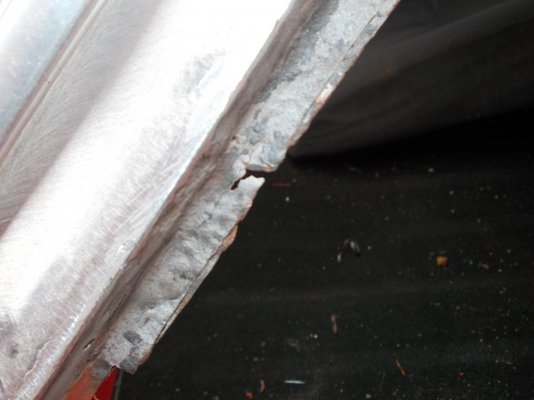

hi, done some more on the rear valance. used the remainig sheet to use as a straight edge to mark the first fold what a bitch! folder not deep enough

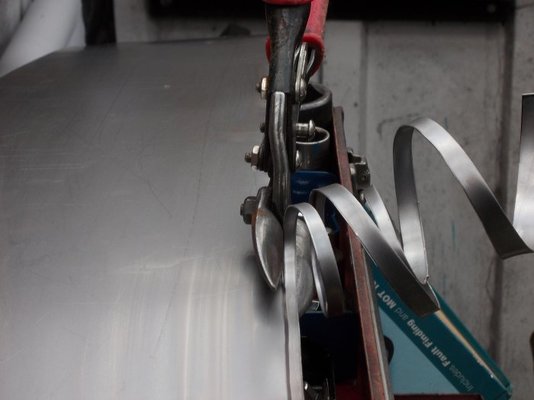

what a bitch! folder not deep enough  have to do it this way

have to do it this way clamed up for hammering in some "kinks" to rest the angle against

clamed up for hammering in some "kinks" to rest the angle against then clamped up and knocked over with a flipper

then clamped up and knocked over with a flipper and test fit

and test fit bent by hand then started tapping lower edge into shape

bent by hand then started tapping lower edge into shape made a template for shaping the ends as original

made a template for shaping the ends as original like so!

like so! and that'll do for today still needs more work on the lower edge and holes drilling for wiring but that can wait for another day

and that'll do for today still needs more work on the lower edge and holes drilling for wiring but that can wait for another day

what a bitch! folder not deep enough

what a bitch! folder not deep enough  have to do it this way

have to do it this way clamed up for hammering in some "kinks" to rest the angle against

clamed up for hammering in some "kinks" to rest the angle against then clamped up and knocked over with a flipper

then clamped up and knocked over with a flipper and test fit

and test fit bent by hand then started tapping lower edge into shape

bent by hand then started tapping lower edge into shape made a template for shaping the ends as original

made a template for shaping the ends as original like so!

like so! and that'll do for today still needs more work on the lower edge and holes drilling for wiring but that can wait for another day

and that'll do for today still needs more work on the lower edge and holes drilling for wiring but that can wait for another day

jpmillermatic

Member

- Messages

- 1,094

thanks for showing us the process you used to get that panel to start to fit into place...As I work more with metal....the beginning stages are key to getting the panel to fit ultimately....

JP

JP

This thread is inspiring me to try to fabricate a piece to weld into my Cortina Estate instead of buying a new panel and doing a lot more work, taking it apart and welding in a whole front panel as opposed to a small section.

I only need this bit replaced …

And the front valance straightened.

CheeRS,

Aaron.

I only need this bit replaced …

And the front valance straightened.

CheeRS,

Aaron.

if the rest of the panel is solid then a small repair piece is going to be the way to go but if theres holes in several places then your best cutting the lot out. the valance i reckon will straighten if you put a piece of wood behind where the upper and lower panels are welded together and hit it with a large plastic hammer, best of luck with it

Nice work. I recognise that folder, I have one just like it

Dave

good design aint it? although the next one i build will be longer and a bit deeper

good design aint it? although the next one i build will be longer and a bit deeper

done some more today, trimmed the lower edge looks a bit more even

looks a bit more even and got the holes cut for the wiring

and got the holes cut for the wiring clamped up and a bit of minor tweaking done

clamped up and a bit of minor tweaking done

now concerned that the neighbours might think they'd gone deaf and supposing that the panel above the valance might be worse than it looks......

now concerned that the neighbours might think they'd gone deaf and supposing that the panel above the valance might be worse than it looks...... i thought i'd have a go at making one of these as well! if i dont need it i'll put it in the loft 'til i do!

i thought i'd have a go at making one of these as well! if i dont need it i'll put it in the loft 'til i do!

looks a bit more even

looks a bit more even and got the holes cut for the wiring

and got the holes cut for the wiring clamped up and a bit of minor tweaking done

clamped up and a bit of minor tweaking done

now concerned that the neighbours might think they'd gone deaf and supposing that the panel above the valance might be worse than it looks......

now concerned that the neighbours might think they'd gone deaf and supposing that the panel above the valance might be worse than it looks...... i thought i'd have a go at making one of these as well! if i dont need it i'll put it in the loft 'til i do!

i thought i'd have a go at making one of these as well! if i dont need it i'll put it in the loft 'til i do!

Springerdinger

memoirs of the mediocre diy mechanic

- Messages

- 435

- Location

- UK nr Southam

Hi Ian

just read through the thread and wanted to say how amazing your work is

it goes to show everything can be repaired by the right minded person.

inspiring workmenship

cheers

Chris

just read through the thread and wanted to say how amazing your work is

it goes to show everything can be repaired by the right minded person.

inspiring workmenship

cheers

Chris

hi quick update, not too much done due to welder finally giving up. bought a clarke 151en from mm on the last vat free day so back onto the car ,got the upper valance removed and as suspected it was quite heavily rusted on the inside and had taken most of the bumper mounts with it!

so back onto the car ,got the upper valance removed and as suspected it was quite heavily rusted on the inside and had taken most of the bumper mounts with it! [/ATTACH] just needed to make repair sections for the boot slam panel.

[/ATTACH] just needed to make repair sections for the boot slam panel.  so tap tap tap...

so tap tap tap... [/ATTACH]

[/ATTACH]

will need some tweaking but hoping to get them welded in this week sometime

will need some tweaking but hoping to get them welded in this week sometime

so back onto the car ,got the upper valance removed and as suspected it was quite heavily rusted on the inside and had taken most of the bumper mounts with it!

so back onto the car ,got the upper valance removed and as suspected it was quite heavily rusted on the inside and had taken most of the bumper mounts with it! [/ATTACH] just needed to make repair sections for the boot slam panel.

[/ATTACH] just needed to make repair sections for the boot slam panel.  so tap tap tap...

so tap tap tap... [/ATTACH]

[/ATTACH]

will need some tweaking but hoping to get them welded in this week sometime

will need some tweaking but hoping to get them welded in this week sometime

jpmillermatic

Member

- Messages

- 1,094

great progress on this one!.....

looks like you have worked your way around the whole car?...whats left?

JP

looks like you have worked your way around the whole car?...whats left?

JP

great progress on this one!.....

looks like you have worked your way around the whole car?...whats left?

JP

not much actually

i need to get these parts welded in then it's a little work on the doors nothing major, check in case i've missed anything then prep for the respray

i need to get these parts welded in then it's a little work on the doors nothing major, check in case i've missed anything then prep for the respray

drivers side inner valance repaired and passenger side

and passenger side  just need to make a piece about five feet long to join the two! so in the mean time i got on with the drivers lower rear wing which needs to be done before the the valances go on as they go over it if you see what i mean, so onto the inner repair good job i REALLY like welding upside down

just need to make a piece about five feet long to join the two! so in the mean time i got on with the drivers lower rear wing which needs to be done before the the valances go on as they go over it if you see what i mean, so onto the inner repair good job i REALLY like welding upside down

then today the second half going in

then today the second half going in  just needs painting inside then i can fit fit the outer repair panel i made seen here being test fitted

just needs painting inside then i can fit fit the outer repair panel i made seen here being test fitted

and passenger side

and passenger side  just need to make a piece about five feet long to join the two! so in the mean time i got on with the drivers lower rear wing which needs to be done before the the valances go on as they go over it if you see what i mean, so onto the inner repair good job i REALLY like welding upside down

just need to make a piece about five feet long to join the two! so in the mean time i got on with the drivers lower rear wing which needs to be done before the the valances go on as they go over it if you see what i mean, so onto the inner repair good job i REALLY like welding upside down

then today the second half going in

then today the second half going in  just needs painting inside then i can fit fit the outer repair panel i made seen here being test fitted

just needs painting inside then i can fit fit the outer repair panel i made seen here being test fitted

glad you said "THE right minded person" not "A right minded person"

glad you said "THE right minded person" not "A right minded person"