You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pagid brake pads

- Thread starter Bobupndown

- Start date

My global employer tell me to do things too and they're not always necessarily based on sound Engineering judgement either.The difference is, mine is not an opinion, it's hard fact from vehicle manufacturers whose products I have been trained to, and paid to work on - including Mercedes-Benz, many to Master Tech, some to Regional tech level.

Workshop instructions contain the details, procedures, tools and measurements required to perform a task correctly. There is no 'I'll do it the way I think best', the devil is in the detail, if it's not done to the work instructions, it's not done correctly. Fact.

Service procedures are written unambiguously because you have to stipulate a procedure that even the lowest common denominator can follow without having to think. Engineers often disagree with service procedures and sometimes the account managers win.

Ubique

Member

- Messages

- 2,385

- Location

- East Midlands

That looks very much like the grease for the pan. roof runners - yep, just checked the part number on webparts - synthetic grease, WIS lists it for pan roof service.

The only other references are to 'wheel bearing grease (brake paste)' but again, no reference in WIS to applying to braking components.

There are references to caliper slide grease A 000 989 98 00 'lubricating paste' and storage greases.

I'd suggest you don't use any more of that pan. roof grease on brake pads, it has a very low melting point.

The only other references are to 'wheel bearing grease (brake paste)' but again, no reference in WIS to applying to braking components.

There are references to caliper slide grease A 000 989 98 00 'lubricating paste' and storage greases.

I'd suggest you don't use any more of that pan. roof grease on brake pads, it has a very low melting point.

JOEPRO

Member

- Messages

- 5,190

- Location

- UK

My global employer tell me to do things too and they're not always necessarily based on sound Engineering judgement either.

Service procedures are written unambiguously because you have to stipulate a procedure that even the lowest common denominator can follow without having to think. Engineers often disagree with service procedures and sometimes the account managers win.

Car manufacturers have also told us transmissions are sealed for life and don't require oil changes

Just because something isn't in a manual doesn't mean you can't make improvements. As I said before the only brake pad issues I have ever encountered has been the work of others slapping pads in bone dry and is it any wonder in our climate that sometimes only a few weeks later the pads can be seized in the calipers! Or you get brake squeal and / or uneven brake wear. It's a tiny cost and small extra step to add a small smear of grease to critical contact points in a moving assembly and improve things.

You can take a horse to water but you can't make him drink.

Do what you will gentlemen

I service my own cars and for sure I will continue to grease the contact points where I see fit.

I service my own cars and for sure I will continue to grease the contact points where I see fit.keithski122

Member

- Messages

- 2,064

JOEPRO

Member

- Messages

- 5,190

- Location

- UK

That looks very much like the grease for the pan. roof runners - yep, just checked the part number on webparts - synthetic grease, WIS lists it for pan roof service.

The only other references are to 'wheel bearing grease (brake paste)' but again, no reference in WIS to applying to braking components.

There are references to caliper slide grease A 000 989 98 00 'lubricating paste' and storage greases.

I'd suggest you don't use any more of that pan. roof grease on brake pads, it has a very low melting point.

View attachment 484974

You are making assumptions that was my photo. It was a snip from a MB forum guy who does very detailed tutorials and is a MB Tec. It was simply to show that an MB tec is saying to apply grease to contact points of the pads.

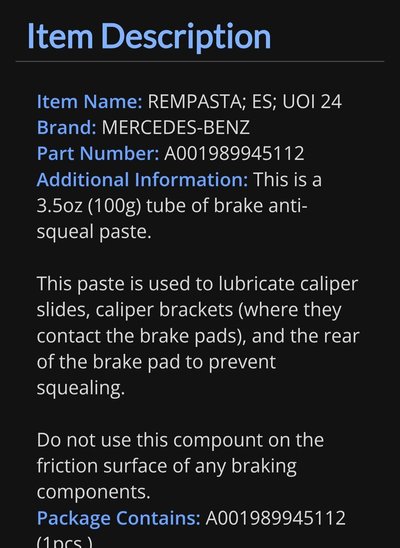

This is what I use among other proprietary brake grease like the ceramic one I posted before:

I have a larger tub of this genuine MB brake grease which includes a brush in the lid for direct application which is handy.

Ubique

Member

- Messages

- 2,385

- Location

- East Midlands

They may well sell it, it is not, however, mandated for use as the fleabay seller seems to imply, in any WIS document relating to brake pads, guides or backings. the specific lubricant for caliper slides have different part numbers, chassis dependent.

I would still question why this 'M-B tech.' is using a pan roof lubricant on brake pads...

I would still question why this 'M-B tech.' is using a pan roof lubricant on brake pads...

JOEPRO

Member

- Messages

- 5,190

- Location

- UK

Here is one recent example of a dry pad slap. My new to me 2017 Mercedes. Private garage had fitted new genuine MB pads and discs about 6 months prior.

See the rust belt on the disc? I had to pry and lever the dry pads out of the calipers. I cleaned all thoroughly and made sure the pads could move freely. I sanded off the rust and sanded the pad flat. It's nearly a new pad just that the rust wears brake pad material instead of cleaning it off.

Small dabs of ceramic grease and with a few k miles since the disc has cleaned up perfect and pads nice and free.

Me and several mechanics I know call this a "pad slap" by your typical garage. No care taken, fit new parts and onto the next.

I am convinced that correct lubrication of the pads on the original installation would have prevented the pads binding and the subsequent rust issue.

I have been meaning to go ahead and remove, clean and grease all pads which I typically do annually on my daily driver car. I am certain the other pads will be binding too going by how this one was. (Car had new genuine brakes all around not long ago)

See the rust belt on the disc? I had to pry and lever the dry pads out of the calipers. I cleaned all thoroughly and made sure the pads could move freely. I sanded off the rust and sanded the pad flat. It's nearly a new pad just that the rust wears brake pad material instead of cleaning it off.

Small dabs of ceramic grease and with a few k miles since the disc has cleaned up perfect and pads nice and free.

Me and several mechanics I know call this a "pad slap" by your typical garage. No care taken, fit new parts and onto the next.

I am convinced that correct lubrication of the pads on the original installation would have prevented the pads binding and the subsequent rust issue.

I have been meaning to go ahead and remove, clean and grease all pads which I typically do annually on my daily driver car. I am certain the other pads will be binding too going by how this one was. (Car had new genuine brakes all around not long ago)

Ubique

Member

- Messages

- 2,385

- Location

- East Midlands

Those discs are well lipped and don't look to be six months old to me, likely the pads have been riding on the edges allowing the discs to corrode - possibly the calipers were not cleaned properly either but i'd be checking those discs for min. thickness as they look too worn to me - unless it's another of your 'gotcha' photos?

But yer, whatever you want to do on your own cars, I have an employer and customers insurers that require the job to be done to manufacturers specifications.

But yer, whatever you want to do on your own cars, I have an employer and customers insurers that require the job to be done to manufacturers specifications.

JOEPRO

Member

- Messages

- 5,190

- Location

- UK

Those discs are well lipped and don't look to be six months old to me, likely the pads have been riding on the edges allowing the discs to corrode - possibly the calipers were not cleaned properly either but i'd be checking those discs for min. thickness as they look too worn to me - unless it's another of your 'gotcha' photos?

But yer, whatever you want to do on your own cars, I have an employer and customers insurers that require the job to be done to manufacturers specifications.

The guy did high miles so there is probably 5 or 10k miles on them in that time yes. Pads have about 10 mm material on em still. Anyways good to hear your opinion on the matter too as a garage employee. At the end of the day it's up to the individual to decide what's works best for them in their circumstances.

premmington

Member

- Messages

- 6,563

- Location

- Norfolk

Those discs are well lipped and don't look to be six months old to me, likely the pads have been riding on the edges allowing the discs to corrode - possibly the calipers were not cleaned properly either but i'd be checking those discs for min. thickness as they look too worn to me - unless it's another of your 'gotcha' photos?

But yer, whatever you want to do on your own cars, I have an employer and customers insurers that require the job to be done to manufacturers specifications.

We will get back to the - should we be fitting discs and pads at the same time debate.

Because this is where all the noise issues come for me - when I put just pads in...

This from the man who just put a set of front pads in only on one of the little Citigos I use for a loaner/courtesy car - I been running round in myself!

Ubique

Member

- Messages

- 2,385

- Location

- East Midlands

True, at least you only have your own insurers (and any third parties) to explain your actions to if it all goes Pete Tong.The guy did high miles so there is probably 5 or 10k miles on them in that time yes. Pads have about 10 mm material on em still. Anyways good to hear your opinion on the matter too as a garage employee. At the end of the day it's up to the individual to decide what's works best for them in their circumstances.

JOEPRO

Member

- Messages

- 5,190

- Location

- UK

JOEPRO

Member

- Messages

- 5,190

- Location

- UK

There are of course other environmental factors which could impact brakes.

The use of caustic / acidic wheel cleaners can of course accelerate corrosion. This could also wash out any pad lubricant.

Whilst most people won't bother, I do think it's important to remove brake pads every year or 2 regardless of mileage and make sure they are moving correctly. Brake fluid also has a service interval so this is a good time to check the pads too.

The use of caustic / acidic wheel cleaners can of course accelerate corrosion. This could also wash out any pad lubricant.

Whilst most people won't bother, I do think it's important to remove brake pads every year or 2 regardless of mileage and make sure they are moving correctly. Brake fluid also has a service interval so this is a good time to check the pads too.

premmington

Member

- Messages

- 6,563

- Location

- Norfolk

There are of course other environmental factors which could impact brakes.

The use of caustic / acidic wheel cleaners can of course accelerate corrosion. This could also wash out any pad lubricant.

Whilst most people won't bother, I do think it's important to remove brake pads every year or 2 regardless of mileage and make sure they are moving correctly. Brake fluid also has a service interval so this is a good time to check the pads too.

Acid wheel cleaners and pressure washers at drive thru car washes.

Funds my workshop income of changing brake calipers I am 100% sure of.

----------

As for stuck pads in hangers - supprises me how many pass the brake loads on MOT rollers and they get advised for thickness - when I go to remove them - they have to chiseled out......

willie.macleod

Member

- Messages

- 909

- Location

- Western Isles, Scotland

And that was my point, they don't come fitted out of the factory with anything but dry mounting shims and (sometimes) sticky pads and / or dense insulating pads, so why do people 'know better' and start adding grease etc., loaded or not. The only parts that are greased are the caliper slide pins and that is a specified grease, not 'whatever grandad used'.

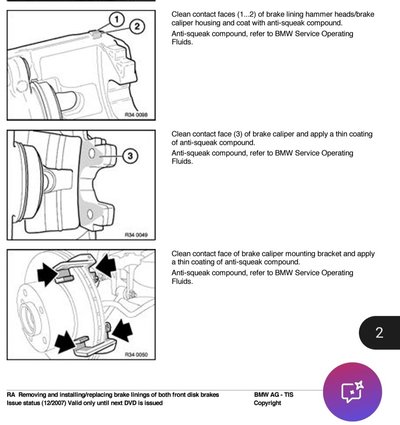

Show me any manufacturers workshop manual where it states 'The contact points of the pad VS caliper should have a small amount of brake grease applied. Lube between pistons and back of pad' and I'll buy the lube for you myself.

Old Defender workshop manual:

keithski122

Member

- Messages

- 2,064

Here's another one for you, when I worked at the mazda dealership in the late nineties we had issues with brake disc corrosion, mazda uk decided this was due to mazda ownership being a higher age group who had been taught to drive using there brakes less than the cars had been designed for. We had to on car brake skim the discs as long as they were in spec, replace the pads for a new harder compound and to advise the customer to use the brakes more often so the harder compound would clean corrosion from discs.

Ubique

Member

- Messages

- 2,385

- Location

- East Midlands

Thanks, that illustrates the point nicely "Old Defender workshop manual" I'm presuming 1980's or 1990's? - that's before modern materials and designs of braking components were used for most vehicles, so it really does reinforce the 'because that's the way we always used to do it' mindset.

Even current replacements for older braking systems incorporate progression in materials, so even with old vehicles, it's not always necessary or a good idea to lubricate the moving parts.

willie.macleod

Member

- Messages

- 909

- Location

- Western Isles, Scotland

Yes, the defender manual I quoted from is from the 1990s. The next vehicle sitting beside it on the drive is my Leaf which is very clear about what should be greased and exactly what grease to use;

willie.macleod

Member

- Messages

- 909

- Location

- Western Isles, Scotland

And just out of interest I double checked the next car up, the xc90. Volvo say to lubricate the pad ends with silicone grease;