You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have fixed today

- Thread starter qwakers

- Start date

Blue Chips

Forum Supporter

- Messages

- 756

- Location

- Maine, USA

Just finished repairing the rest of the plaster and cornice damage in the 'north parlor' of our project house. Wherever possible, I used lime putty plaster (lime putty, sand, and hemp or animal hair) in three coats: scratch coat, brown coat, and finish coat. I mix it quite stiff/dry to reduce shrinkage cracking, which makes it quite a bit of work to apply and smooth out, but I like the fact that lime putty plaster gives me a lot of working time, which is good since I'm not particularly fast at plastering. The main challenge in this room was to repair the fancy plaster cornice moulding, which was damaged in multiple places. Ideally, one would start from scratch and set up a track tor a 'horse' (sliding template) and 'run' the cornice in multiple passes, but this was a repair job, not a start-from-scratch job. Still, I applied some of the same techniques to the repair job.

Here are some 'before' photos:

Note the damage to the cornice moulding against the ceiling. There were probably a dozen places that needed repair.

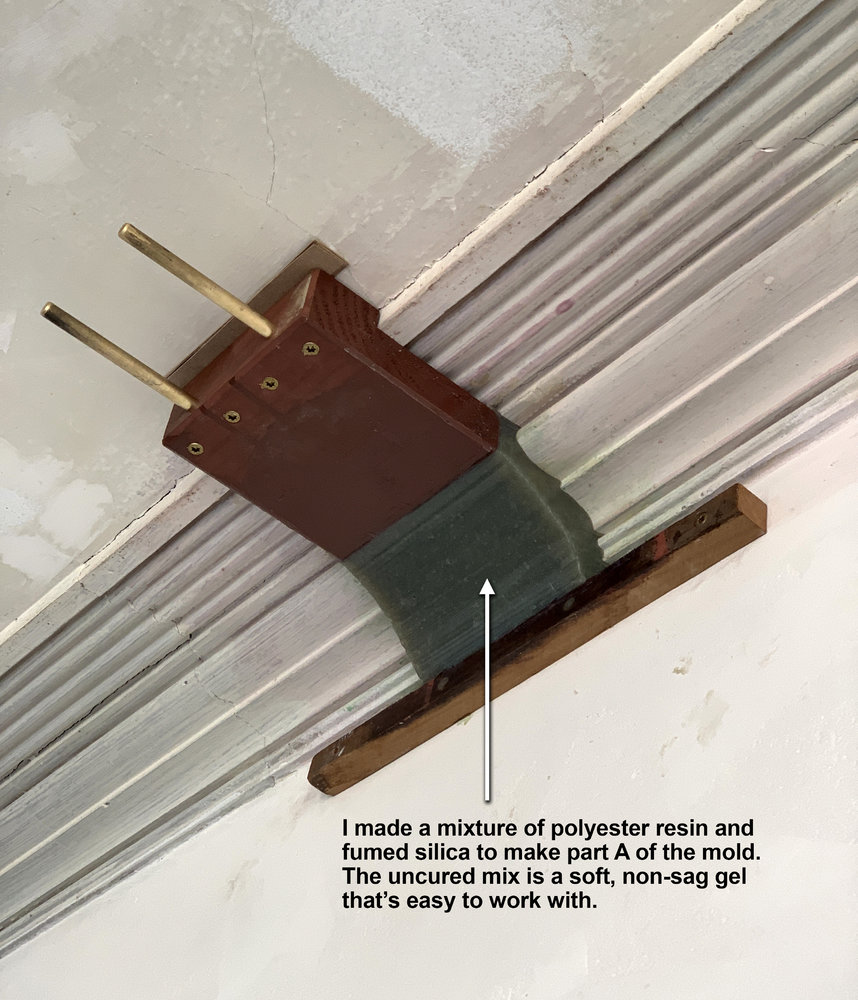

To make a template tool for repairing the cornice, I started by making a two-part mold from an undamaged section of the cornice. I had to do this in two parts because of the undercuts. This is the jig I made to make the first section of the mold:

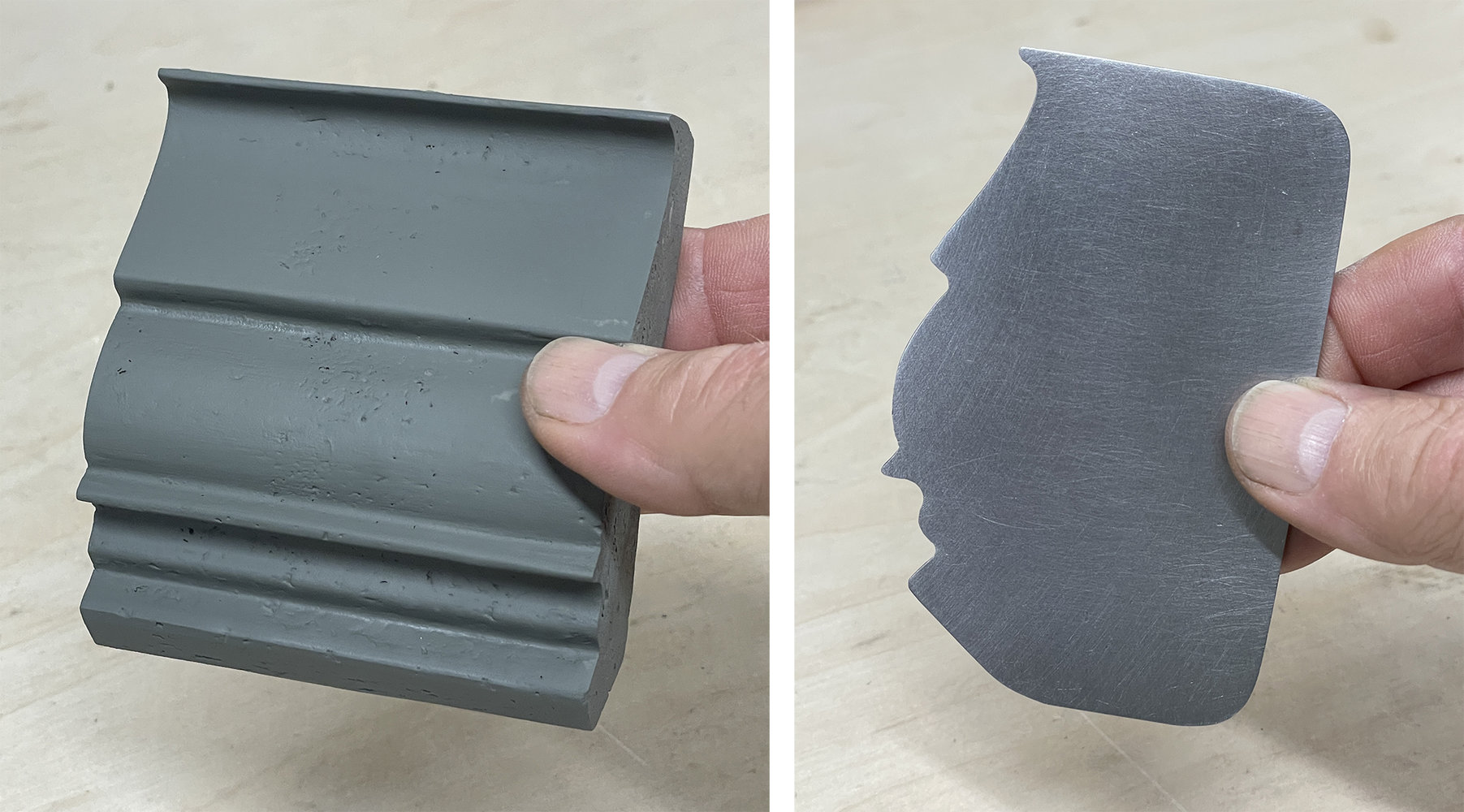

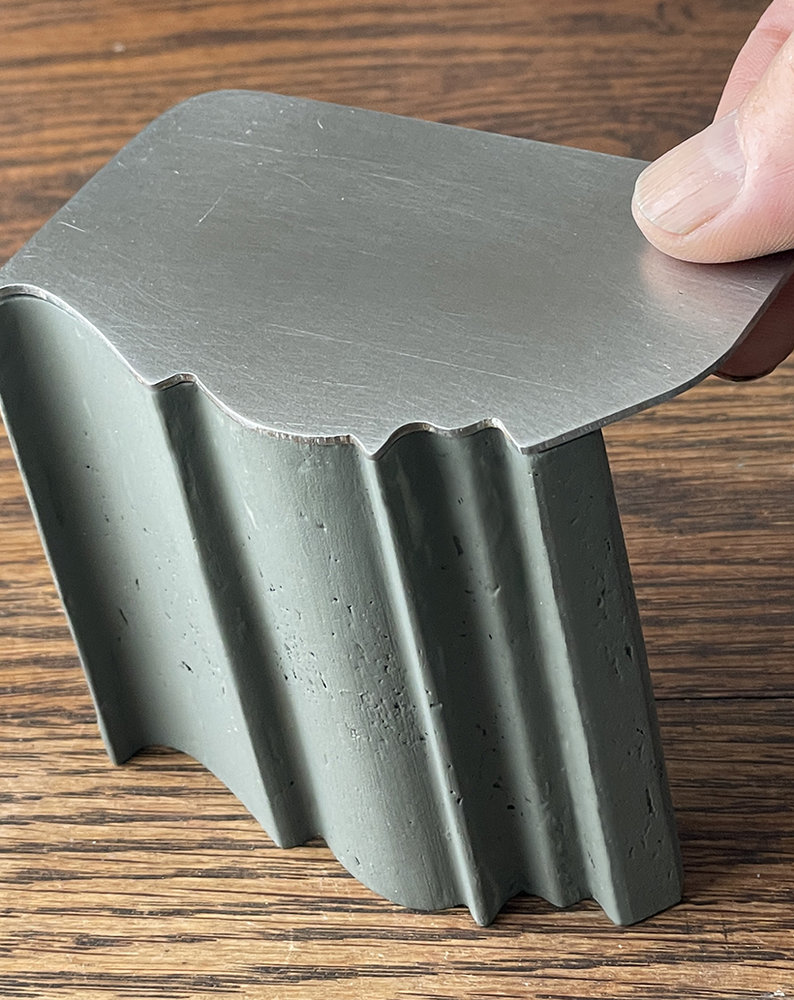

I had experimented earlier with using the polyester resin mold itself as a sliding template for shaping the cornice repair plaster, but it didn't work very well, so this time I used the polyester resin mold as a guide for making a steel template like a traditional cornice expert would use, except that I slid it along the cornice by hand instead of attaching it to a 'horse' that slides along a track.

Anyway, after messing about with it for a while and trying different plaster mixes, I finally got the hang of things and managed to drag new plaster across the cornice fairly smoothly to fill in missing areas. The fluted part of the cornice was easier.

Here's an 'after' photo of the same damaged cornice shown above. It ain't absolutely perfect, but I'm happy with it. It still needs another coat of primer, which will help hide some of the minor glitches.

The north parlor is now pretty much done. It's primed and ready to paint with any color scheme. The floor boards are original. We stripped the paint off of them, but we didn't try to sand out more than 200 years of old stains, scuffs, and wear (character ). I used penetrating polyurethane rather than oil, and the old wood soaked up about four applications, so it's well protected. The floor boards were re-nailed with wrought-head nails like the originals. The new light fixtures for the parlors should be arriving tomorrow.

). I used penetrating polyurethane rather than oil, and the old wood soaked up about four applications, so it's well protected. The floor boards were re-nailed with wrought-head nails like the originals. The new light fixtures for the parlors should be arriving tomorrow.

Here are some 'before' photos:

Note the damage to the cornice moulding against the ceiling. There were probably a dozen places that needed repair.

To make a template tool for repairing the cornice, I started by making a two-part mold from an undamaged section of the cornice. I had to do this in two parts because of the undercuts. This is the jig I made to make the first section of the mold:

I had experimented earlier with using the polyester resin mold itself as a sliding template for shaping the cornice repair plaster, but it didn't work very well, so this time I used the polyester resin mold as a guide for making a steel template like a traditional cornice expert would use, except that I slid it along the cornice by hand instead of attaching it to a 'horse' that slides along a track.

Anyway, after messing about with it for a while and trying different plaster mixes, I finally got the hang of things and managed to drag new plaster across the cornice fairly smoothly to fill in missing areas. The fluted part of the cornice was easier.

Here's an 'after' photo of the same damaged cornice shown above. It ain't absolutely perfect, but I'm happy with it. It still needs another coat of primer, which will help hide some of the minor glitches.

The north parlor is now pretty much done. It's primed and ready to paint with any color scheme. The floor boards are original. We stripped the paint off of them, but we didn't try to sand out more than 200 years of old stains, scuffs, and wear (character

). I used penetrating polyurethane rather than oil, and the old wood soaked up about four applications, so it's well protected. The floor boards were re-nailed with wrought-head nails like the originals. The new light fixtures for the parlors should be arriving tomorrow.

). I used penetrating polyurethane rather than oil, and the old wood soaked up about four applications, so it's well protected. The floor boards were re-nailed with wrought-head nails like the originals. The new light fixtures for the parlors should be arriving tomorrow.

Last edited:

Not personally, but on my behalf - this massive leak on a 3" water main on the farm that we had no idea was there - not on SE Waters plans. Seems to be a branch off a 10" main that we did know about.

Fixed with a bolt on band aid !

Fixed with a bolt on band aid !

dan.taylor.1

General Tinkererer

- Messages

- 2,750

- Location

- Kendal, Cumbria

That's nothing, Manchester aqua duct from thirlmere runs right through our farm, had a lot more surface water about than we'd had rain one year, called them up, "yes we'd noticed a bit of pressure loss"..!Not personally, but on my behalf - this massive leak on a 3" water main on the farm that we had no idea was there - not on SE Waters plans. Seems to be a branch off a 10" main that we did know about.

Fixed with a bolt on band aid !

No visible surface leak, so they traced it and found the culprit, their man was happily digging away with a 13t machine till woosh, bucket and boom damn near get blasted to the side, and a 100+ft spout of water appears, they had shut the pipe section in question (apparently about 5 or 6ft diameter!) but because of the sheer pressure and volume still in it it took several days to stop leaking.

They had to import some special repair section from Germany I think... Apparently was losing 1000000 litres of water a day or something daft!

You know the rules Dan, No photos and it didn't happenThat's nothing, Manchester aqua duct from thirlmere runs right through our farm, had a lot more surface water about than we'd had rain one year, called them up, "yes we'd noticed a bit of pressure loss"..!

No visible surface leak, so they traced it and found the culprit, their man was happily digging away with a 13t machine till woosh, bucket and boom damn near get blasted to the side, and a 100+ft spout of water appears, they had shut the pipe section in question (apparently about 5 or 6ft diameter!) but because of the sheer pressure and volume still in it it took several days to stop leaking.

They had to import some special repair section from Germany I think... Apparently was losing 1000000 litres of water a day or something daft!

dan.taylor.1

General Tinkererer

- Messages

- 2,750

- Location

- Kendal, Cumbria

This was pre camera phones and not sure we took any, they were pretty high on security.You know the rules Dan, No photos and it didn't happen

They went round a few years back and there was mention of adding anti terrorism alarms to all the access hatches...

Sergei Slovenija

Member

- Messages

- 1,256

- Location

- Slovenija Ljubljana

Do not do that.View attachment 414522

think I need to hone the cilinderwall or get a stronger spring. View attachment 414524

What, stronger spring or honing?Do not do that.

I say honing but wat I mean is fine emery cloth to smoothen the surface a little.

Spring seems a little weak but to find a fitting one that has the correct strength is going to be a challenge.

Cilinder is depressed (on-off) by a big air actuator so I don't think it is really critical.

Fintray

Member

- Messages

- 846

- Location

- Aberdeenshire (UK)

This company might be able to help:What, stronger spring or honing?

I say honing but wat I mean is fine emery cloth to smoothen the surface a little.

Spring seems a little weak but to find a fitting one that has the correct strength is going to be a challenge.

https://www.ashfield-springs.com/compression-springs

Sergei Slovenija

Member

- Messages

- 1,256

- Location

- Slovenija Ljubljana

from what I can see the rubber seals are worn out. Honing the cylinder with sandpaper is definitely not worth it. Flex-hone for manual work will give the necessary surface cleanliness. What is an amplifier, a pneumatic actuator or a vacuum amplifier, is not so important. If the main brake booster fails, either buy a new one or buy a complete repair kit. There may be wear and tear further down the hydraulic component chain. You need to audit the entire system.What, stronger spring or honing?

I say honing but wat I mean is fine emery cloth to smoothen the surface a little.

Spring seems a little weak but to find a fitting one that has the correct strength is going to be a challenge.

Cilinder is depressed (on-off) by a big air actuator so I don't think it is really critical.View attachment 414541

This can cause pain in the wallet.

This is an ultra slow hobby machine never going on public roads.from what I can see the rubber seals are worn out. Honing the cylinder with sandpaper is definitely not worth it. Flex-hone for manual work will give the necessary surface cleanliness. What is an amplifier, a pneumatic actuator or a vacuum amplifier, is not so important. If the main brake booster fails, either buy a new one or buy a complete repair kit. There may be wear and tear further down the hydraulic component chain. You need to audit the entire system.

This can cause pain in the wallet.

The reason I would like brakes is for stability while digging. Buying a new one if possible, is out of the picture at the moment. If it leaks I will consider new seals if I can find them.

The corrosion pitting is relatively small so I hope I can still fix this.

I don't have a Flex-hone for manual work, do you think it is so much better then emery cloth wound on a suitable piece of wood?

I find the returnspring is very weak and don't see a problem in a little stronger one helping the piston to return, giving the full stroke for the next brake action. The booster can easily overcome this spring I think.

The rest of this brake system is defenately going be inspected, I am scaling up on tools at the moment, to be able to change the wheels

MattF

Forum Supporter

- Messages

- 18,537

- Location

- South Yorkshire

Drilled & tapped a fixing point which had been missed during manufacture.

It's for a screw to secure the bottom rear of a cover in position.

As you can tell, the brass rod was in the lathe, so...

.

The other screws were replaced with brass thumbscrews too.

The rear of that cover is now as it ought be, rather than flapping out.

It's for a screw to secure the bottom rear of a cover in position.

As you can tell, the brass rod was in the lathe, so...

.

The other screws were replaced with brass thumbscrews too.

The rear of that cover is now as it ought be, rather than flapping out.

Thumbscrews abound in yourThe other screws were replaced with brass thumbscrews too.

I've got one of those little linishers, just checked and that fixing point on mine is also missing, shame the belt case door is plastic, as apart from that they are solid little things. Think I'll copy that and replace with thumbscrews - which means I need to buy a knurling tool...

Arc Tourist

Member

- Messages

- 5,054

- Location

- Wales

Consider using socket head cap screw's with a press on knurled cap. Easily squeezed on with a vice, and a good solution for many applications.Thumbscrews abound in yourdungeonworkshop

I've got one of those little linishers, just checked and that fixing point on mine is also missing, shame the belt case door is plastic, as apart from that they are solid little things. Think I'll copy that and replace with thumbscrews - which means I need to buy a knurling tool...

MattF

Forum Supporter

- Messages

- 18,537

- Location

- South Yorkshire

Thumbscrews abound in yourdungeonworkshop

I've got one of those little linishers, just checked and that fixing point on mine is also missing, shame the belt case door is plastic, as apart from that they are solid little things. Think I'll copy that and replace with thumbscrews - which means I need to buy a knurling tool...

Any reason to buy another tool is a good one.

Adding a screw near that dust port firms that cover up nicely. Should help improve extraction too. They're M4 thread.

Adding a screw near that dust port firms that cover up nicely. Should help improve extraction too. They're M4 thread.MattF

Forum Supporter

- Messages

- 18,537

- Location

- South Yorkshire

Consider using socket head cap screw's with a press on knurled cap. Easily squeezed on with a vice, and a good solution for many applications.View attachment 414894

Are they brass?

- Messages

- 13,490

- Location

- England

Ensuite toilet flush was constantly dripping into the pan. Removed, scraped the scale off the sealing washer seat, added a little silicone grease. Sounds like it's sorted. 10 minute job to fix something annoying. Always forget about it until bed time usually.

Arc Tourist

Member

- Messages

- 5,054

- Location

- Wales

I've only seen them in red & black, but I suppose you could touch them up with brass paint.Are they brass?