Seadog

Save the planet. It's the only one with rum!

- Messages

- 13,005

- Location

- NE London - UK

Some jobs just seem to go on and on.

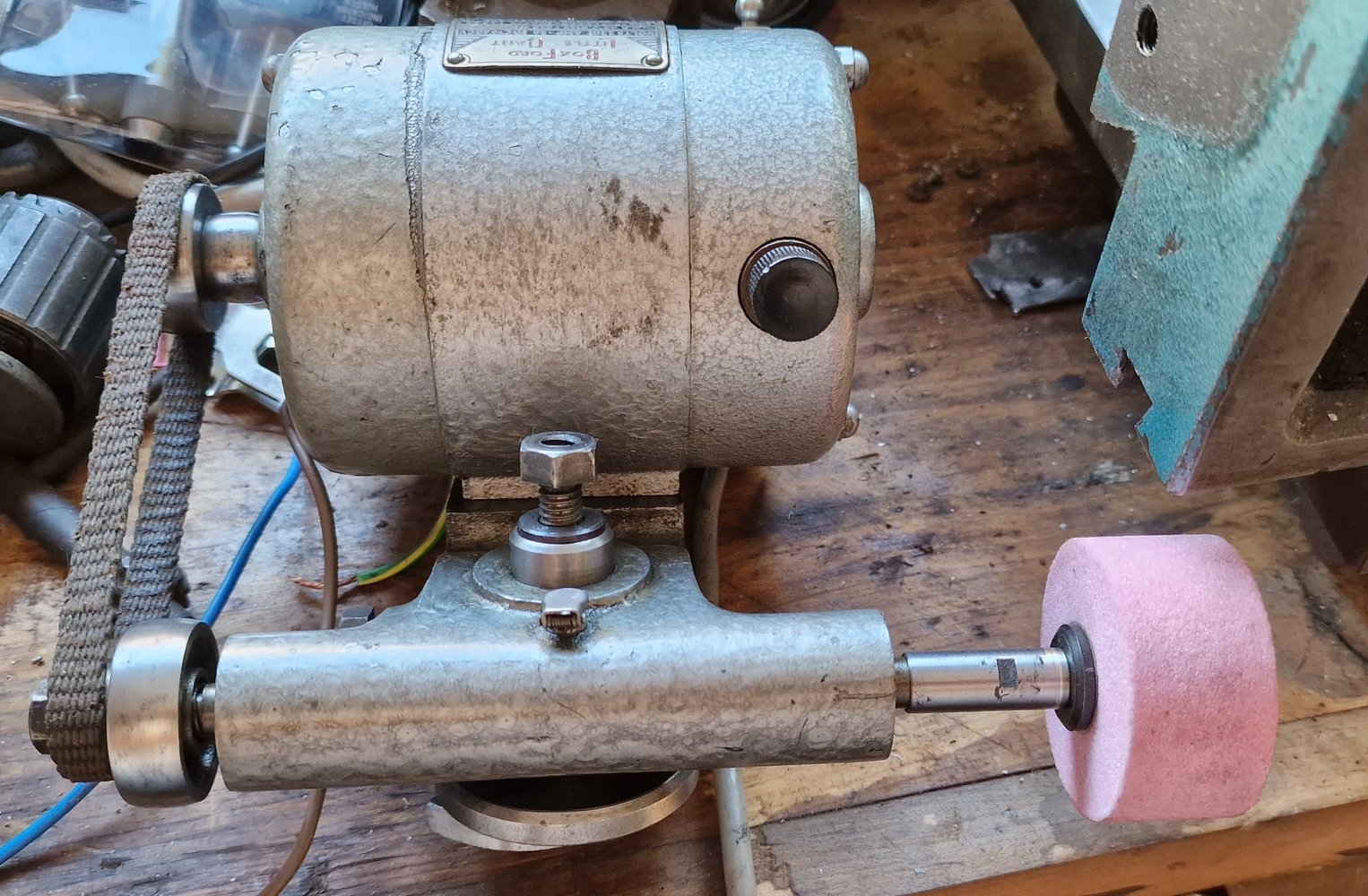

I attempted to use my as-yet untried tool post grinder. That ended up with a complete rebuild

Today I gave it another go, only to find that the stone arbour was bent. It had been badly repaired (no image) so I had to put it right.

Cue some lathe work and silver soldering. I tuned the threaded part off, then drilled the body ready to tap it to screw another piece in. Only to discover that that had already been done and a poor bit of silver soldering had been resulted in the thread being slightly off-centre. The shaft had then been skimmed, but was still out of true and undersize.

I just bored the end with a 1/4" slot drill, turned a stub to go in, and then silver soldered it, before turning to size and threading the end. I took the opportunity to lengthen it by a few millimetres as well. The main spindle is either 1/4" x 32 ME or 1/4" x 32 UNEF. I thought it prudent to have a tap just in case the silver solder went where it shouldn't have done. It didn't, but I've still got a taper and plug, plus a die coming from Tracey Tools. Only £12 all-in.

Hopefully tomorrow I can get on with grinding the ends of the ball screws to diameter

I attempted to use my as-yet untried tool post grinder. That ended up with a complete rebuild

Today I gave it another go, only to find that the stone arbour was bent. It had been badly repaired (no image) so I had to put it right.

Cue some lathe work and silver soldering. I tuned the threaded part off, then drilled the body ready to tap it to screw another piece in. Only to discover that that had already been done and a poor bit of silver soldering had been resulted in the thread being slightly off-centre. The shaft had then been skimmed, but was still out of true and undersize.

I just bored the end with a 1/4" slot drill, turned a stub to go in, and then silver soldered it, before turning to size and threading the end. I took the opportunity to lengthen it by a few millimetres as well. The main spindle is either 1/4" x 32 ME or 1/4" x 32 UNEF. I thought it prudent to have a tap just in case the silver solder went where it shouldn't have done. It didn't, but I've still got a taper and plug, plus a die coming from Tracey Tools. Only £12 all-in.

Hopefully tomorrow I can get on with grinding the ends of the ball screws to diameter

That is assuming, of course, that they're fit for purpose.

That is assuming, of course, that they're fit for purpose.