You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

@slim_boy_fat ,I’m just being personal,wouldn’t tell the customer that,unless they asked for my suggestion or opinions,she didn’t and appeared confident when sh ordered it.

Scalarocco

Smile, or I'll bite your leg...

- Messages

- 485

- Location

- Rossendale

The customer is always right...unless they're wrong, obviously.How so? Extra work = Extra £££££, surely?(Actually, I quite like it, it's.....different from all the other gates.

)

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

I fired up my birthday present Park side plasma cutter with internal compressor ( 21 Dec ) for the first time .

RTFM'ing the manual at least half a dozen times in the last month or so to get familiar with what I was about to do .

RTFM'ing the manual at least half a dozen times in the last month or so to get familiar with what I was about to do .

All set, workmate bench outside , no chance of hot metal getting sprayed around or on me ..especially on me . Welding helmet on, Soft leather TIG welding gloves on . I clamped a 19 x 19 inch plate of ( scrap ) 5 mm thick aluminium tread plate to the work bench, used a clamped down 1/4 inch thick strip of wood as a guide & set it up for cutting at setting 20 .

Nothing zilch.. OMG the earths not connected to the plate , it's still on the end of the wooden strip That sorted all I got was a big fat egg yolk yellow pea of glow at the cutting tip .

OMG the earths not connected to the plate , it's still on the end of the wooden strip That sorted all I got was a big fat egg yolk yellow pea of glow at the cutting tip .

Hmmm... that doesn't seem right . looked carefully at the tip and it's melted into a black pea sized copper ball . Stripped down the gun and pondered , WTF have I done wrong ? Ran through the destructions again .... twice..

Ah haaa ( I love these Ah haaa moments when they solve things ) I'd set the compressed air in valve to closed ..... correctly and had tested it by putting on the air in feed tube and trying to blow through it .

What I hadn't done was put the rocker switch at the front RH top of the machine from EXT, to INT so it could set the internal compressor to work .. I'd only tried high voltage plasma cutting with no air

I'd only tried high voltage plasma cutting with no air .

.

Suitably " embrassed "

Suitably " embrassed "  I set it to INT , set up the wooden guide rail again & away I went . What an amazing bit of kit, I should have got one years ago.

I set it to INT , set up the wooden guide rail again & away I went . What an amazing bit of kit, I should have got one years ago.

I needed to up the current to 40 to get a really thin cutting line but as it was my first session and having no previous experience with plasma I think I did well.

I needed to up the current to 40 to get a really thin cutting line but as it was my first session and having no previous experience with plasma I think I did well.

The first 19 inch cut length was a bit ragged, second was better the next five 19 inch strips cut were even better .

No 15 yr old scrap boiler, washing machine , dish washer, cooker, fridge or freezer etc is now safe from me.

No 15 yr old scrap boiler, washing machine , dish washer, cooker, fridge or freezer etc is now safe from me.

Found a couple of times when I changed standing position that a melt of aluminium particles had solidified in a couple of places , so I need a gripper to hold things whilst I broke the formation up . Understanding that one continuous even speed draw is the best way not to get problems .

They cleaned up well with a flap wheel on my 4 inch grinder , better than when on previous occasions I cut them on my bandsaw or after using the jigsaw to cut some .

RTFM'ing the manual at least half a dozen times in the last month or so to get familiar with what I was about to do .

RTFM'ing the manual at least half a dozen times in the last month or so to get familiar with what I was about to do .All set, workmate bench outside , no chance of hot metal getting sprayed around or on me ..especially on me . Welding helmet on, Soft leather TIG welding gloves on . I clamped a 19 x 19 inch plate of ( scrap ) 5 mm thick aluminium tread plate to the work bench, used a clamped down 1/4 inch thick strip of wood as a guide & set it up for cutting at setting 20 .

Nothing zilch..

OMG the earths not connected to the plate , it's still on the end of the wooden strip That sorted all I got was a big fat egg yolk yellow pea of glow at the cutting tip .

OMG the earths not connected to the plate , it's still on the end of the wooden strip That sorted all I got was a big fat egg yolk yellow pea of glow at the cutting tip .Hmmm... that doesn't seem right . looked carefully at the tip and it's melted into a black pea sized copper ball . Stripped down the gun and pondered , WTF have I done wrong ? Ran through the destructions again .... twice..

Ah haaa ( I love these Ah haaa moments when they solve things ) I'd set the compressed air in valve to closed ..... correctly and had tested it by putting on the air in feed tube and trying to blow through it .

What I hadn't done was put the rocker switch at the front RH top of the machine from EXT, to INT so it could set the internal compressor to work ..

I'd only tried high voltage plasma cutting with no air

I'd only tried high voltage plasma cutting with no air .

. Suitably " embrassed "

Suitably " embrassed "  I set it to INT , set up the wooden guide rail again & away I went . What an amazing bit of kit, I should have got one years ago.

I set it to INT , set up the wooden guide rail again & away I went . What an amazing bit of kit, I should have got one years ago. I needed to up the current to 40 to get a really thin cutting line but as it was my first session and having no previous experience with plasma I think I did well.

I needed to up the current to 40 to get a really thin cutting line but as it was my first session and having no previous experience with plasma I think I did well.The first 19 inch cut length was a bit ragged, second was better the next five 19 inch strips cut were even better .

No 15 yr old scrap boiler, washing machine , dish washer, cooker, fridge or freezer etc is now safe from me.

No 15 yr old scrap boiler, washing machine , dish washer, cooker, fridge or freezer etc is now safe from me.Found a couple of times when I changed standing position that a melt of aluminium particles had solidified in a couple of places , so I need a gripper to hold things whilst I broke the formation up . Understanding that one continuous even speed draw is the best way not to get problems .

They cleaned up well with a flap wheel on my 4 inch grinder , better than when on previous occasions I cut them on my bandsaw or after using the jigsaw to cut some .

Last edited:

slim_boy_fat

Member

- Messages

- 29,187

- Location

- Scottish Highlands

What an amazing bit of kit, I should have got one years ago.

Good fun, aren't they?

Erie Fred

Member

- Messages

- 6,556

- Location

- Erie, Pa USofA

My renter dropped this off, and asked me to drive it, as he was busy.Yeah 8 furrow, have a NH 7.270 on the front, we'll weighted up. In light sticky soil the slats don't trail soil as bad as a solid board, in the autumn on stiffer land like the photo the slats generally break it up a bit more so making it easier for the drill. We only have disks on the back furrow, ive never saw a plough with full disks round here.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

T'would be amusingly nice to take that down town shopping and see if they can put a wheel clamp on the motor because you are a few inches over the line into the next parking bayMy renter dropped this off, and asked me to drive it, as he was busy.View attachment 383430

Fraserb

Member

- Messages

- 1,525

- Location

- Scottish Borders

My renter dropped this off, and asked me to drive it, as he was busy.View attachment 383430

It's a strange experience driving one of those.

Erie Fred

Member

- Messages

- 6,556

- Location

- Erie, Pa USofA

Yes, unlike a regular dozer. It has a steering wheel, and a single brake pedal.It's a strange experience driving one of those.

Renter dropped it off sat night when I wasn't there.

I called him on sunday, all his instructions were this:

"1800 rpm, 8th gear, drop the disc's down, and raise them up slightly on the wheels when plowing, run the xport wheels

all the way down when turning...bye."

First thing, check oil & water, figure out how to "Turn it off, before you learn how to turn it on"

(that one has saved my bacon a few times)

Open all winders & doors to dissapate mouse pee vapors (didn't work all too well).

Crank it over, figure out powershift xmission.

Driving one with one foot out of the cab, to get most of your nose outside (for breathable air) is "different".

Last edited:

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,360

- Location

- Sevenoaks, UK

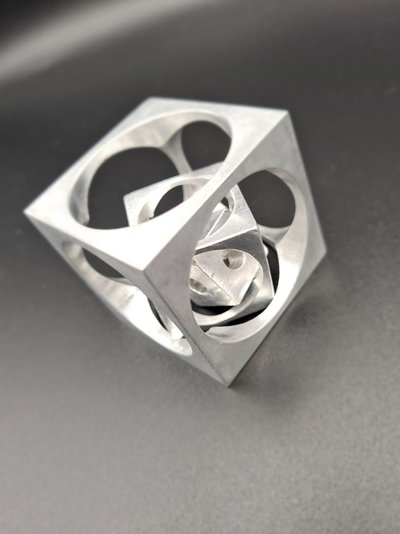

Made mostly last night, finished off deburring/cleanup today.

No reason, just fancied making one.

View attachment 383399

I'd love a dual extruder.

????I'd love a dual extruder.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

I've bee busy today inbetweeen rest breaks

First up was to chop the aluminium strips I plasma cut yesterday & bend them into right angle brackets ( after annealing them ) . They are to support the diesel heaters hot air out pipe work, when it's attached to the garage wall about 1/3 of the way in . Having drilled and countersunk the mounting holes I realised that having a slot in the longest leg of each bracket would be welcome , to slide the pipe back to the wall and tighten up a diddy coach bolt to secure it there.

Got another excuse to play with eplasma cutter .

Starting on the left , the first slot cut to Mk 1 eyeball precision ... a blind man would be pleased to se it is about all I can say about the aesthetics and uniformity of the slot

Second on the left was cut free hand to fine Sharpie lines and drilled start holes . Least said about that one the better . it has a useable elongated hole

Then I had a brain storm, why not cut out between odd leg calliper scribed lines in 1/4 " scrap strip wood allow a few mm for the nozzle diameter and give it a go with it securely clamped to the bracket .... in the right position .

I chickened out , did a trial burn out on a bit of the same metal scrap. Wow worked better than I'd hoped .

Third bracket is a lot better hardly any filing to get it rectangular

Forth bracket was even better , next time I'll run some 2" x 1/4 inch thick oak strips up on the bench saw make a strip for the spacer gap in the slot as wide as the slot I want then glue them up , leave to set over night in the airing cupboard and then use the mask of wood for plasma hole cutting the next day . I reckon with a few experiments and making the cutting slot just a tad bigger than the diameter of the nozzle I might be looking at 2.5 mm wide straight slots in 5 mm alu.

I dare say I could have purchased the brackets and clamping parts from somewhere after doing a few hours online searching but where is the fun in doing that and paying for them at the same time ?

First up was to chop the aluminium strips I plasma cut yesterday & bend them into right angle brackets ( after annealing them ) . They are to support the diesel heaters hot air out pipe work, when it's attached to the garage wall about 1/3 of the way in . Having drilled and countersunk the mounting holes I realised that having a slot in the longest leg of each bracket would be welcome , to slide the pipe back to the wall and tighten up a diddy coach bolt to secure it there.

Got another excuse to play with eplasma cutter .

Starting on the left , the first slot cut to Mk 1 eyeball precision ... a blind man would be pleased to se it is about all I can say about the aesthetics and uniformity of the slot

Second on the left was cut free hand to fine Sharpie lines and drilled start holes . Least said about that one the better . it has a useable elongated hole

Then I had a brain storm, why not cut out between odd leg calliper scribed lines in 1/4 " scrap strip wood allow a few mm for the nozzle diameter and give it a go with it securely clamped to the bracket .... in the right position .

I chickened out , did a trial burn out on a bit of the same metal scrap. Wow worked better than I'd hoped .

Third bracket is a lot better hardly any filing to get it rectangular

Forth bracket was even better , next time I'll run some 2" x 1/4 inch thick oak strips up on the bench saw make a strip for the spacer gap in the slot as wide as the slot I want then glue them up , leave to set over night in the airing cupboard and then use the mask of wood for plasma hole cutting the next day . I reckon with a few experiments and making the cutting slot just a tad bigger than the diameter of the nozzle I might be looking at 2.5 mm wide straight slots in 5 mm alu.

I dare say I could have purchased the brackets and clamping parts from somewhere after doing a few hours online searching but where is the fun in doing that and paying for them at the same time ?

Last edited:

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Second success of the day but not yet fitted is a big black lightly knurled Delrin knob to carry the plasma cutter's trigger lead plug .

The lead is terminated in a fiddly plug that has the 20 mm dia retaining ring sat in a 30 mm high x 40 mm wide recess , sat back 14,5 mm from the casings front edges.

Being diabetic & having had frostbite in my hands & feet years ago has left my with desensitized pinky tips ,.

Putting the plug in the socket and tightening the retainer nut was difficult and as I don't have space to leave it assembled I take the leads off it when I put it away .

A quick measure up witha cheapie vernier caliper gove the nut diameter as 20 mm and the 14.5 deep socket hole .

I found one of half a dozen scrapped experimental self-leveling floor adhesive rollers made in 1.5 inch thick Delrin . Made up a quick bodgers mandrel with a sort of cone on the end and , then using a proper lathe chuck mandrel put the Delrin roller in the middle and turned it down to 40 mm external then re chucked everything and turned a 9'16 Dai through hole up to 20 mm dia , rechucked again put a 30 mm step on one ends , re-chucked it again and knurled the major diameter . Did a couple of test fits to ensure nothing was untoward ,

Chopped the plug off the lead leaving a tiny bit of coloured sleeving as an ID device and pushed the plug body with retaining ring in place into the knob taking care it went in on the right side , did another test fit just to be 100 % sure it works.

Offending recessed plug socket in the midgle bottom of the picture

Simple top hat , knurled , bigger knob with a few mm clearance when full home after fitting & tightening .

Knurled knob in place less the cable and cable retaining nut it's a massive improvement on the original fiddly bit .

Tomorrow morning I'll solder the wires on & refit the cable retention / stress relief device nut .

The lead is terminated in a fiddly plug that has the 20 mm dia retaining ring sat in a 30 mm high x 40 mm wide recess , sat back 14,5 mm from the casings front edges.

Being diabetic & having had frostbite in my hands & feet years ago has left my with desensitized pinky tips ,.

Putting the plug in the socket and tightening the retainer nut was difficult and as I don't have space to leave it assembled I take the leads off it when I put it away .

A quick measure up witha cheapie vernier caliper gove the nut diameter as 20 mm and the 14.5 deep socket hole .

I found one of half a dozen scrapped experimental self-leveling floor adhesive rollers made in 1.5 inch thick Delrin . Made up a quick bodgers mandrel with a sort of cone on the end and , then using a proper lathe chuck mandrel put the Delrin roller in the middle and turned it down to 40 mm external then re chucked everything and turned a 9'16 Dai through hole up to 20 mm dia , rechucked again put a 30 mm step on one ends , re-chucked it again and knurled the major diameter . Did a couple of test fits to ensure nothing was untoward ,

Chopped the plug off the lead leaving a tiny bit of coloured sleeving as an ID device and pushed the plug body with retaining ring in place into the knob taking care it went in on the right side , did another test fit just to be 100 % sure it works.

Offending recessed plug socket in the midgle bottom of the picture

Simple top hat , knurled , bigger knob with a few mm clearance when full home after fitting & tightening .

Knurled knob in place less the cable and cable retaining nut it's a massive improvement on the original fiddly bit .

Tomorrow morning I'll solder the wires on & refit the cable retention / stress relief device nut .

I've use wood templates with great success with a plasma - for a quick and easy template for limited use they work well. Admittedly after a few uses, they do seem to smell a bit singedThen I had a brain storm, why not cut out between odd leg calliper scribed lines in 1/4 " scrap strip wood allow a few mm for the nozzle diameter and give it a go with it securely clamped to the bracket .... in the right position .

I chicken'd out did a tria;l burn out on a bit of the same metal scrap. Wow worked better than I'd hoped .

Third bracket is a lot better hardly any filing to get it rectangular

Forth bracket was even better , next time I'll run some 2" x 1/4 inch thick oak strips up on the bench saw make a strip for the spacer gap in the slot as wide as the slot I want then glue them up , leave to set over night in the airing cupboard and then use the mask of wood for plasma hole cutting the next day . I reckon with a few experiments and making the cutting slot just a tad bigger than the diameter of the nozzle I might be looking at 2.5 mm wide straight slots in 5 mm alu.

I dare say I could have purchased the brackets and clamping parts from somewhere after doing a few hours online searching but where is the fun in doing that and paying for them at the same time ?

View attachment 383503View attachment 383504

I use hardboard templates. I have various sized circles, squares and even long straight lengths. Seem to last ok.I wonder if thick hard board is any better or some of one of the thinner heat resisting soft files , such as go behind boilers etc. in stud walled internals