prepman

Forum Supporter

- Messages

- 2,770

- Location

- Gwynedd UK

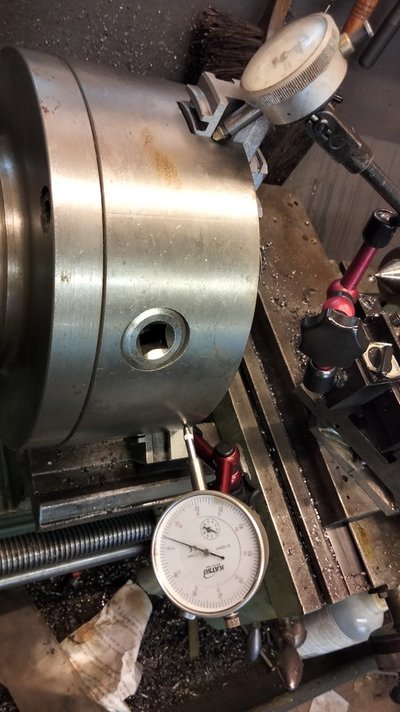

Because of a pretty nasty parting operation and an indication of tapering, I needed to check alignment. I also adjusted the ball bearing feed safety clutch on the feed shaft and changed all oils. Clamped the saddle to test it. OK.

Next was to check alignment.

Did a few tests on the lathe. Clock gauges on the chuck to see if any change.

Slackened the headstock bolts tapped and retightened. Changed on cross axis.

Machined the test bar gripped in chuck and got 0.025mm difference over 200mm. I can live with that.

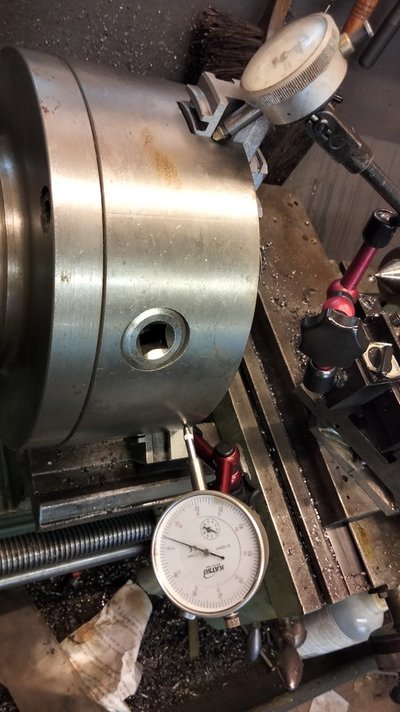

Then I used the test bar between centres.

Horrendous! The results gave a ridiculous taper, didn't even need to measure it.

The results gave a ridiculous taper, didn't even need to measure it.

Ran the centres together.... Yipes! Thought I'd try a different centre.

Yipes! Thought I'd try a different centre.

More respectable. So lesson learnt.... using a tailstock centre to check tailstock alignment can give false results. The 1st centre is from the ML7 and needed a MT adaptor. I suspect there lies the answer.

Still haven't concluded anything on pre-loading the headstock bearings. Nothing seems condusive. Perhap Gamet cus serv will help, or not?

Next was to check alignment.

Did a few tests on the lathe. Clock gauges on the chuck to see if any change.

Slackened the headstock bolts tapped and retightened. Changed on cross axis.

Machined the test bar gripped in chuck and got 0.025mm difference over 200mm. I can live with that.

Then I used the test bar between centres.

Horrendous!

The results gave a ridiculous taper, didn't even need to measure it.

The results gave a ridiculous taper, didn't even need to measure it.Ran the centres together....

Yipes! Thought I'd try a different centre.

Yipes! Thought I'd try a different centre.

More respectable. So lesson learnt.... using a tailstock centre to check tailstock alignment can give false results. The 1st centre is from the ML7 and needed a MT adaptor. I suspect there lies the answer.

Still haven't concluded anything on pre-loading the headstock bearings. Nothing seems condusive. Perhap Gamet cus serv will help, or not?

Last edited:

'Light the blue touch paper and retire to a safe distance'

'Light the blue touch paper and retire to a safe distance'