Hood

Member

- Messages

- 17,984

- Location

- Carnoustie, Scotland

The POS getting a bit more love today

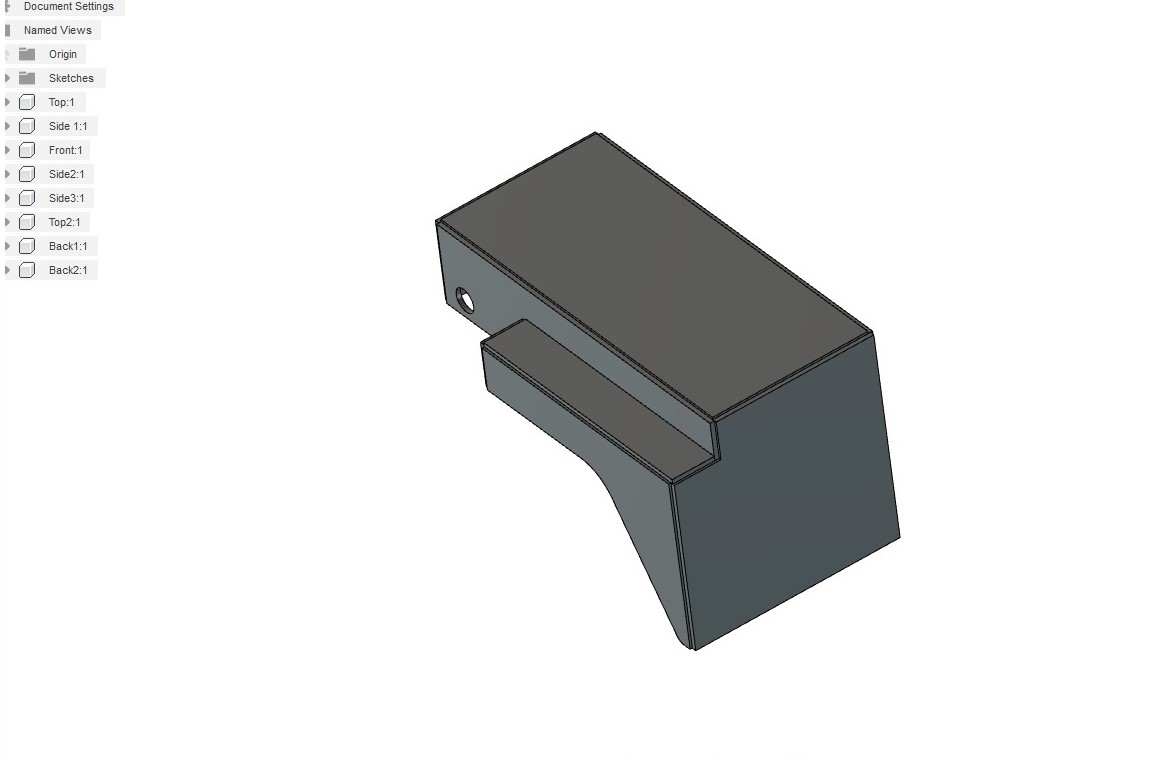

Chuck guard was broken when I got the lathe 10+ years ago.

So last night I measured it and did a model.

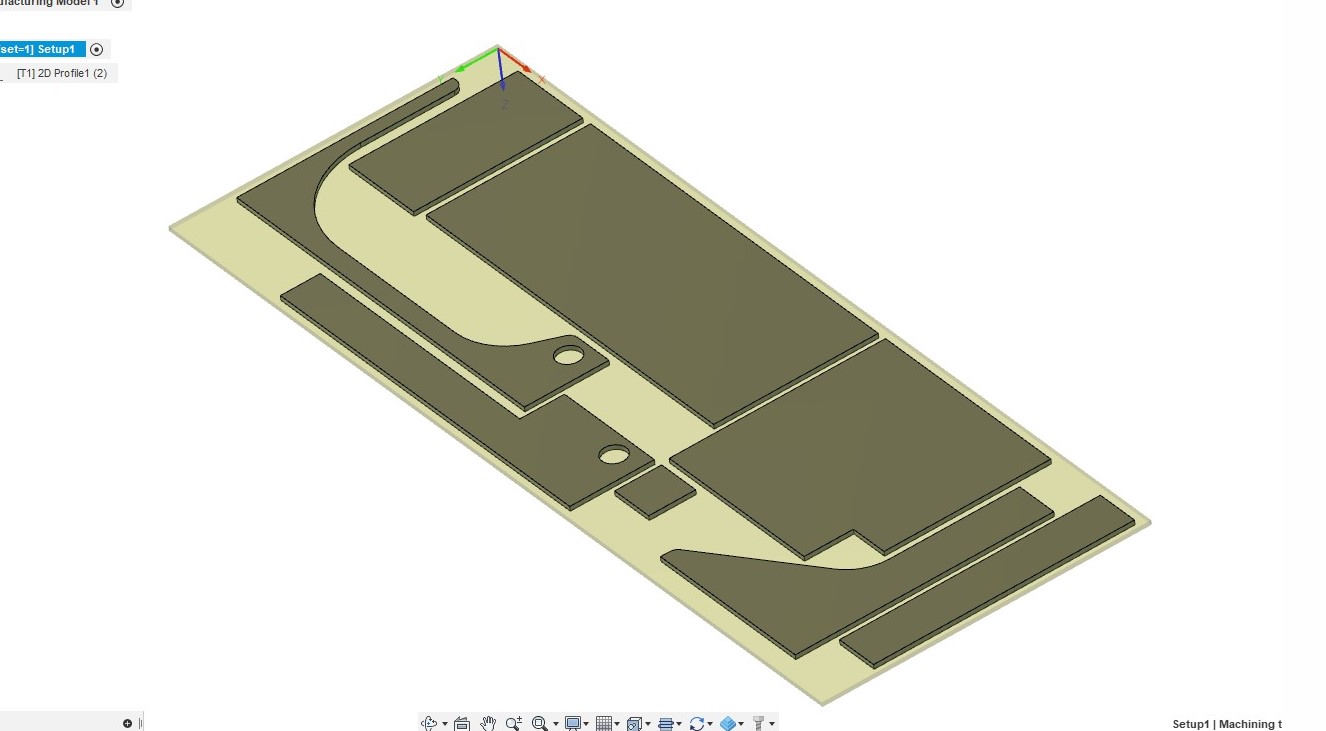

Arranged for getting the code and cutting on the plasma.

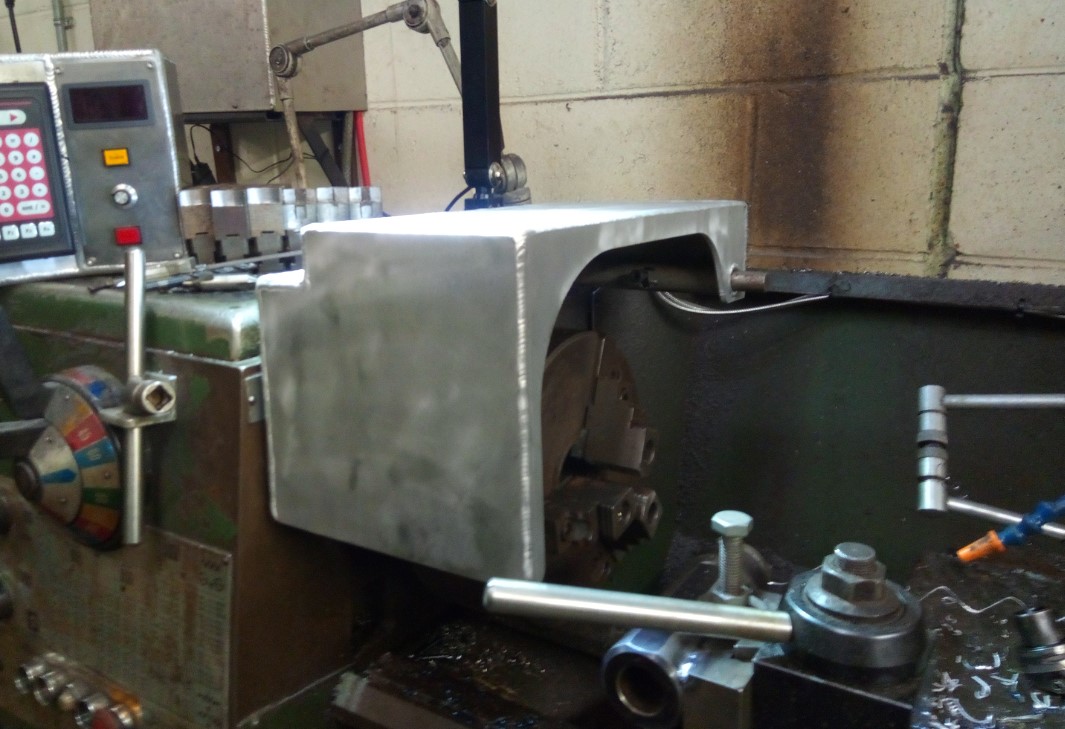

This afternoon I had a bit of spare time so cut the parts and stuck them together.

Fitted to the POS.

Also made up a rack for the Capto tooling.

Only problem is some dopey B forgot about the tailstock handle, it fits under fine for sliding but when trying to lock it hits the rack. I have a few options but will have a better look when I get a chance and see which would be best/easiest.

Chuck guard was broken when I got the lathe 10+ years ago.

So last night I measured it and did a model.

Arranged for getting the code and cutting on the plasma.

This afternoon I had a bit of spare time so cut the parts and stuck them together.

Fitted to the POS.

Also made up a rack for the Capto tooling.

Only problem is some dopey B forgot about the tailstock handle, it fits under fine for sliding but when trying to lock it hits the rack. I have a few options but will have a better look when I get a chance and see which would be best/easiest.

Is it because you use flood coolant?

Is it because you use flood coolant?