You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Today I acquired...........

- Thread starter monkeymark

- Start date

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Aye, but from her post Mrs b will be working at one stage in a very small space.

I offer to Mrs b …

Weld up a 50mm equal angle iron dolly trolley and put it on 100 mm hard nylon locking castors . add some 150 mm U channels to take the legs of the stand & once the stand is correctly sited weld the channels in place you can then build the stand ( with shelves ?) , mount the bed on it and move it about with ease as you sort out the other bits of the lathe . Having it on a dolly has the advantage of being able to clean behind under or around it easily or find tiny bits that fall behind it when you're parting things off. It's also less problematic when repainting the workshop wall behind it matt white . As I'm 80 % disabled ...having my lathe on a dolly & stand has also allowed me to use a 2 ton chain hoist to lift the heavier bits on and off it when the dolly is put under the strongest beam in the garage . It also allows me to pull the lathe out to reset set the gibs on the carriage and slide easily as they are at the back of the lathe .

Cuthy246

Member

- Messages

- 924

- Location

- Scotland, Highlands

Thanks Seadog, pulley size is pretty much identical so think it is original. Started cleaning it up today, table came up quite nice. Will start a separate thread for its restoration. Thinking of getting a treadmill motor to power it, variable speed so can do metal and wood without changing pulleys.I couldn't get to the motor last night. It's under a ton of stuff, but here's some pictures of the belt cover. Let me know if you need more detailed measurements.

The pulley on the drive wheel is approximately 6 1/4" diameter. when I can get to the motor I'll measure that too, I think it may be the same.

View attachment 168690 View attachment 168691 View attachment 168692

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,696

- Location

- North Kent, UK

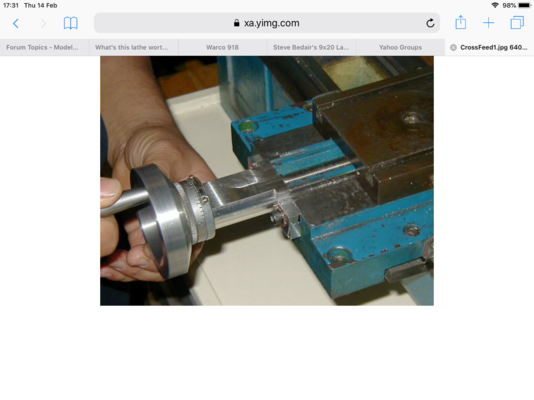

I have a picture from the interweb.

Is that a pic of the bit that’s missing?

mrsbruce

Member

- Messages

- 1,960

- Location

- Livingston, Scotland

I offer to Mrs b …

Weld up a 50mm equal angle iron dolly trolley and put it on 100 mm hard nylon locking castors . add some 150 mm U channels to take the legs of the stand & once the stand is correctly sited weld the channels in place you can then build the stand ( with shelves ?) , mount the bed on it and move it about with ease as you sort out the other bits of the lathe . Having it on a dolly has the advantage of being able to clean behind under or around it easily or find tiny bits that fall behind it when you're parting things off. It's also less problematic when repainting the workshop wall behind it matt white . As I'm 80 % disabled ...having my lathe on a dolly & stand has also allowed me to use a 2 ton chain hoist to lift the heavier bits on and off it when the dolly is put under the strongest beam in the garage . It also allows me to pull the lathe out to reset set the gibs on the carriage and slide easily as they are at the back of the lathe .

That sounds an even better plan, but for the space I have, I might have to adapt it a bit, because once the table is in place, there is no room to move it about.

But...... If I make the table lower, then make dolly tray (with low profile locking wheels) to fit the lathe onto, that would allow the lathe to be moved about the table when stuff needs done, and the wheels can be locked or moved up(?) when it’s in use.

Mmmm..........

mrsbruce

Member

- Messages

- 1,960

- Location

- Livingston, Scotland

Is that a pic of the bit that’s missing?

Yes, although it might be someone’s home made replacement/upgrade in the picture, but yes, that’s the missing bracket.

Another view of the bracket (shiny T shape between handwheel and cross slide).

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,696

- Location

- North Kent, UK

Yes, although it might be someone’s home made replacement/upgrade in the picture, but yes, that’s the missing bracket.

Another view of the bracket (shiny T shape between handwheel and cross slide).

That’s almost identical to the repair that my lathe has. I got it from @Pete. a few years ago. He got it as a fixer upper and it too had very similar damage. He made a brilliant job of the repair, and I’m still chuffed to bits with it 2 or 3 years down the line!

I’ll get some pics done later and post them up. I MAY have the original damaged part so we can have a measure up and get some sizes for you.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Because of having a bust up spine in two places & a wrecked left shoulder I've raised my cutting tip up another four inches by putting the lathe on the dolly .. now it's at a good height for me . I hope to be able to use the lathe well into old age 80yrs or so as it means I don't have to lean over or put my head downwards to work the lathe & I can bum sit on the edge of a tall stool & can get my toes under the lathe so I can stand just that bit nearer . Adding a times six back lit angle poise magnifying arm so the glass & light comes over the chuck area is also very advantageous , having an LED lit times 10 magnifying glass attached to the carriage to cover the tool tip might be even better ..That sounds an even better plan, but for the space I have, I might have to adapt it a bit, because once the table is in place, there is no room to move it about.

But...... If I make the table lower, then make dolly tray (with low profile locking wheels) to fit the lathe onto, that would allow the lathe to be moved about the table when stuff needs done, and the wheels can be locked or moved up(?) when it’s in use.

Mmmm..........

eLuSiVeMiTe

Member

- Messages

- 16,282

- Location

- ......

Oh how well I know that feeling. Everytime something new arrives its a complete reshuffle to make things fit.A customer called in to work before going to the tip

A double set of old metal draws

View attachment 168343

Then i started to move things around

View attachment 168344

Then it just got worse

View attachment 168345

Result on the drawers. Could do with a few more myself.

eLuSiVeMiTe

Member

- Messages

- 16,282

- Location

- ......

Might have to hunt that post down for another cheeky offer lol.Welcome to the club

Shed being converted into a wood shop this summer.

slim_boy_fat

Member

- Messages

- 29,187

- Location

- Scottish Highlands

brewdexta

The biggest tool in the box

- Messages

- 5,752

- Location

- UK

First the wife acquired her first Valentines day present, 2 tonnes of well rotted horse poo. My neighbour's driving the bobcat as he can do scary things with them that I daren't, yet. The muck was at the top of a steep ramp, and not enough space to spin around at the top. OK coming down with a full bucket but going up with the empty bucket pointing skywards isn't my cup of tea

Her second present was a chipper, she's currently coppicing our woods and wanted lots of mulch for her various veg beds and polytunnel plus I'm sick of tripping over prunings. This is where I picked it up from, it was difficult to get it on my mates plant trailer on my own as the bars that the ramps slide on are bent so they are fixed at their widest, but I summoned my 3 shredded wheat strength and got it on.

Now nestling in the barn before using it in anger tomorrow.

And finally, something for me, I mentioned I wanted another bench in the workshop for the mitre saw, so my neighbour gave me this steel framed bench. Its about 2.6m long, and best of all its quite low, I shall be replacing the top and insetting the mitre saw into it which will raise the finished level from 750 to 900mm so the perfect height.

Cheers

Andy

Her second present was a chipper, she's currently coppicing our woods and wanted lots of mulch for her various veg beds and polytunnel plus I'm sick of tripping over prunings. This is where I picked it up from, it was difficult to get it on my mates plant trailer on my own as the bars that the ramps slide on are bent so they are fixed at their widest, but I summoned my 3 shredded wheat strength and got it on.

Now nestling in the barn before using it in anger tomorrow.

And finally, something for me, I mentioned I wanted another bench in the workshop for the mitre saw, so my neighbour gave me this steel framed bench. Its about 2.6m long, and best of all its quite low, I shall be replacing the top and insetting the mitre saw into it which will raise the finished level from 750 to 900mm so the perfect height.

Cheers

Andy

Last edited:

mrsbruce

Member

- Messages

- 1,960

- Location

- Livingston, Scotland

It does have that home made look to it. No doubt to get some extra cross slide travel.

I think the one on mine was removed either because if damage, or to gain extra travel too. As it is, it can be used, but I’d prefer getting a proper bracket in place.

That’s almost identical to the repair that my lathe has. I got it from @Pete. a few years ago. He got it as a fixer upper and it too had very similar damage. He made a brilliant job of the repair, and I’m still chuffed to bits with it 2 or 3 years down the line!

I’ll get some pics done later and post them up. I MAY have the original damaged part so we can have a measure up and get some sizes for you.

The measurements would be great, if possible. I don’t think it will be too hard to either make a (or preferably adapt an existing) bracket.

@mrsbruce If it's final resting place is going to be close to or against a wall, consider installing a splash-back prior to final siting. Mine was made from the side of a tumble dryer, but only after I'd sprayed mess up the wooden wall.......

Great idea.

I did that for the mini belt sander and mini drill press. I used the bottoms of the drawers of a very rusty filing cabinet (the only bits worth saving, and a great excuse to use the plasma cutter). I have some plastic storage cupboards the hubby used for his overflow tools. I’m making a powder coating ‘booth’ with half of one, and the other half can be turned into a splash back.

You can tell I’ve been planning this.

The_Yellow_Ardvark

I'm a citizen of Legoland travellin' incommunicado

- Messages

- 20,248

- Location

- Going Away.

Today I acquired a cloud.

A small cloud. white and almost fluffy.

It was a jar of mixed solvents, ready to be recycled. But today, every time I opened the jar a cloud would form.

Oh well, the mixture was recycled.

Oh yes, some stiches.

Minor surgery the doc said to remove a splinter of brass. It was in there for years. A small hole the doc said.

1" cut I have.

But I have a nice coffee and a steak.

A small cloud. white and almost fluffy.

It was a jar of mixed solvents, ready to be recycled. But today, every time I opened the jar a cloud would form.

Oh well, the mixture was recycled.

Oh yes, some stiches.

Minor surgery the doc said to remove a splinter of brass. It was in there for years. A small hole the doc said.

1" cut I have.

But I have a nice coffee and a steak.

Jlg

Member

- Messages

- 2,581

- Location

- Cumbria

Why bother if it was in there for years I've got a few bits of metal in my hands that have been there for agesToday I acquired a cloud.

A small cloud. white and almost fluffy.

View attachment 168770

It was a jar of mixed solvents, ready to be recycled. But today, every time I opened the jar a cloud would form.

Oh well, the mixture was recycled.

Oh yes, some stiches.

View attachment 168771

Minor surgery the doc said to remove a splinter of brass. It was in there for years. A small hole the doc said.

1" cut I have.

But I have a nice coffee and a steak.

brightspark

Member

- Messages

- 41,416

- Location

- yarm stockton on tees

any metal shards I get I just cut them out with a Stanley knife

The_Yellow_Ardvark

I'm a citizen of Legoland travellin' incommunicado

- Messages

- 20,248

- Location

- Going Away.

Why bother if it was in there for years I've got a few bits of metal in my hands that have been there for ages

any metal shards I get I just cut them out with a Stanley knife

This was a shard about 4mm long and had worked its way from palm to thumb over the years. In December it decided to fester, not the uncle kind. The pressure then forced it into the knuckle.