8ob

Member

- Messages

- 14,240

- Location

- Nescient in the vale

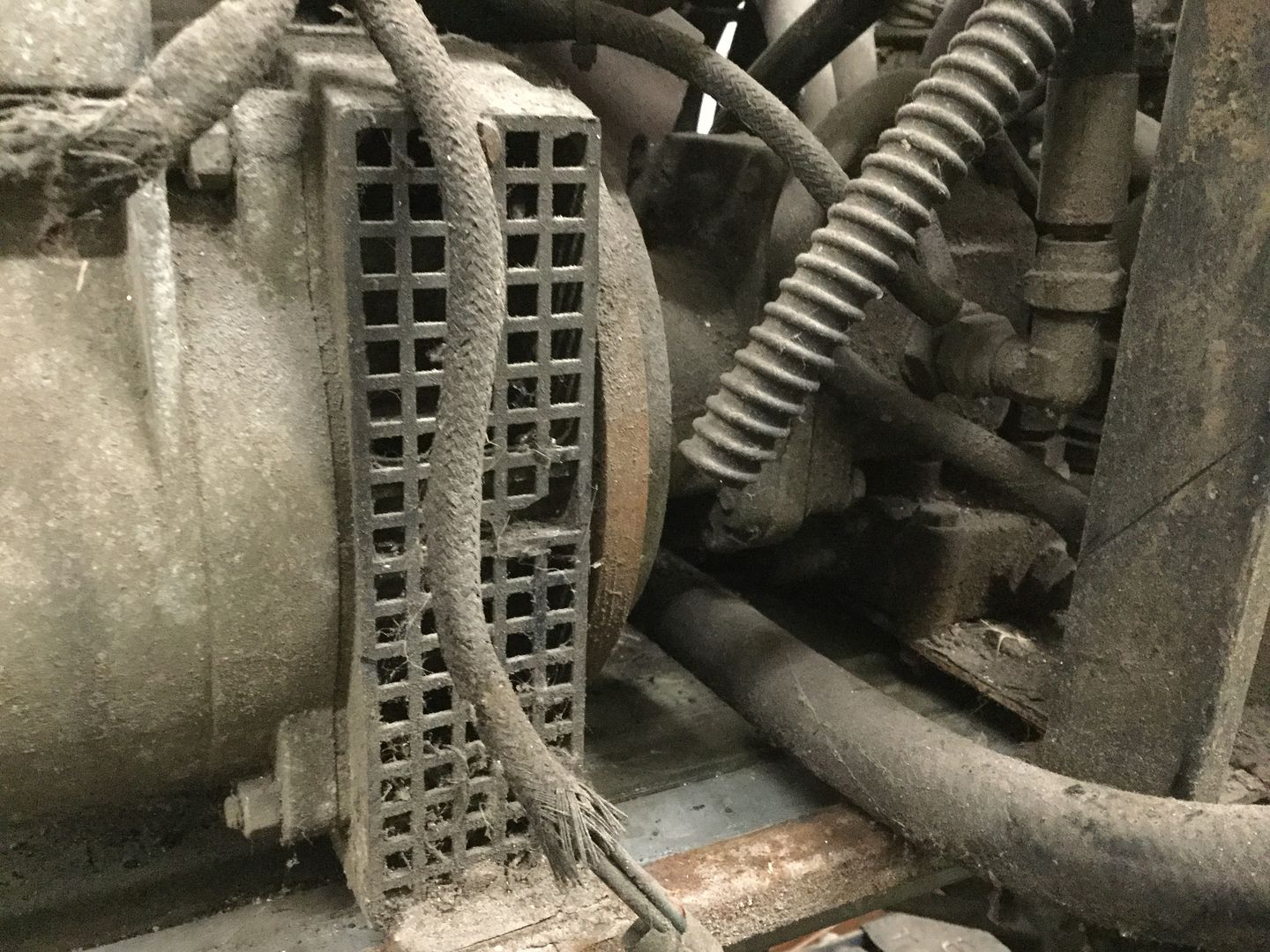

A few small unfinished/forgotten about projects of mine that have been festering in the back of a barn have surfaced , going to get them up and running so I will roll them up into one thread. A three ton digger that is being mongreled to suit forestry work, a 101 landrover service barge for repairng our kit on site and a Stalwart I have just dragged out from under a tree.

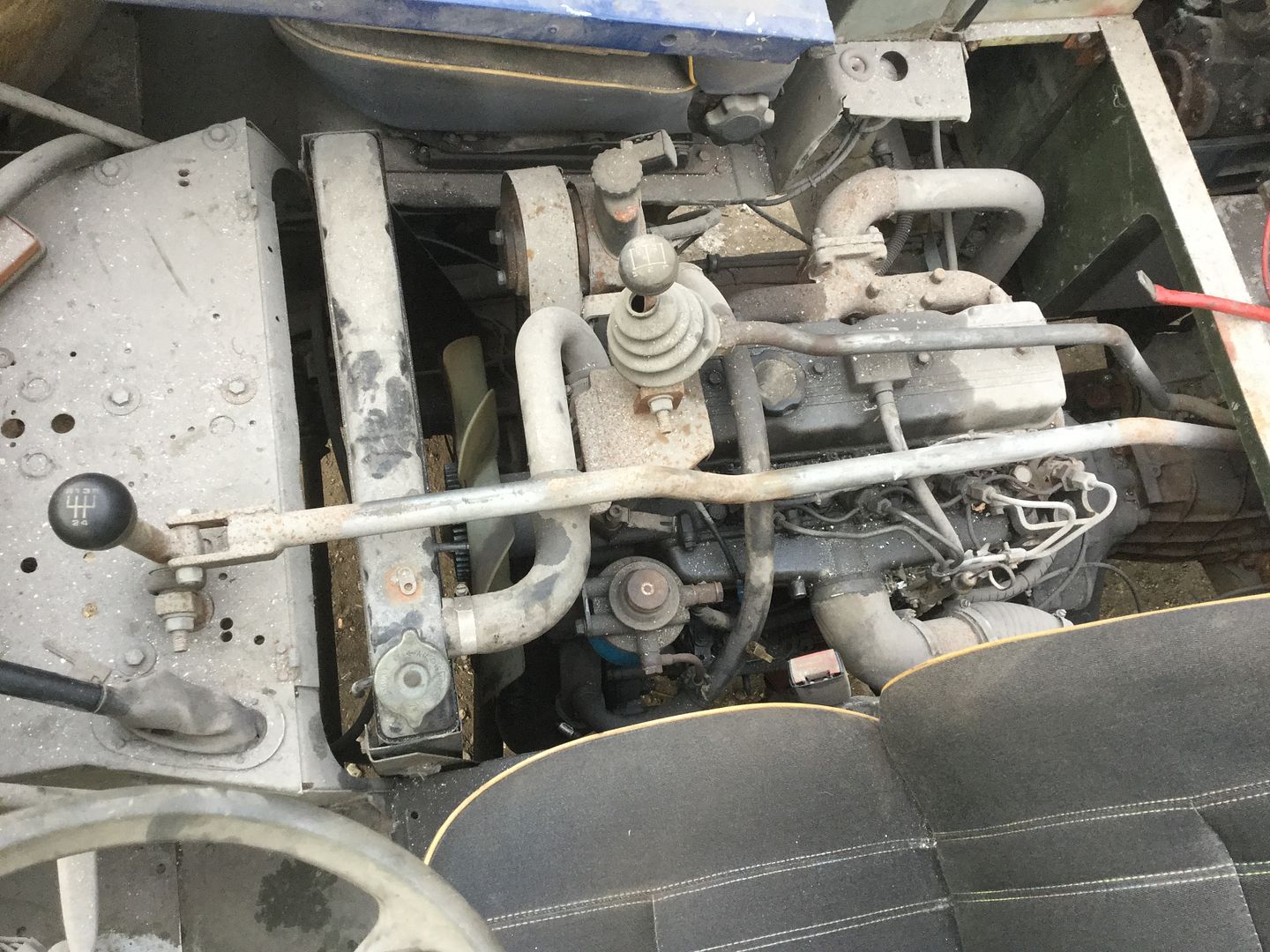

Got the 101 back to the yard, this is an ex Judge Dred landy that had one of those fiberglass body lashups you see in the film. Amazingly rust free.

Work done so far.

1.Junked the V8 petrol and four speed gearbox, fitted a 3ltr mazda/perkins with a five speed LT77 and transfer box, re configured the gear change and transfer box control levers.

2. Made up the props using wide angle UJ`s

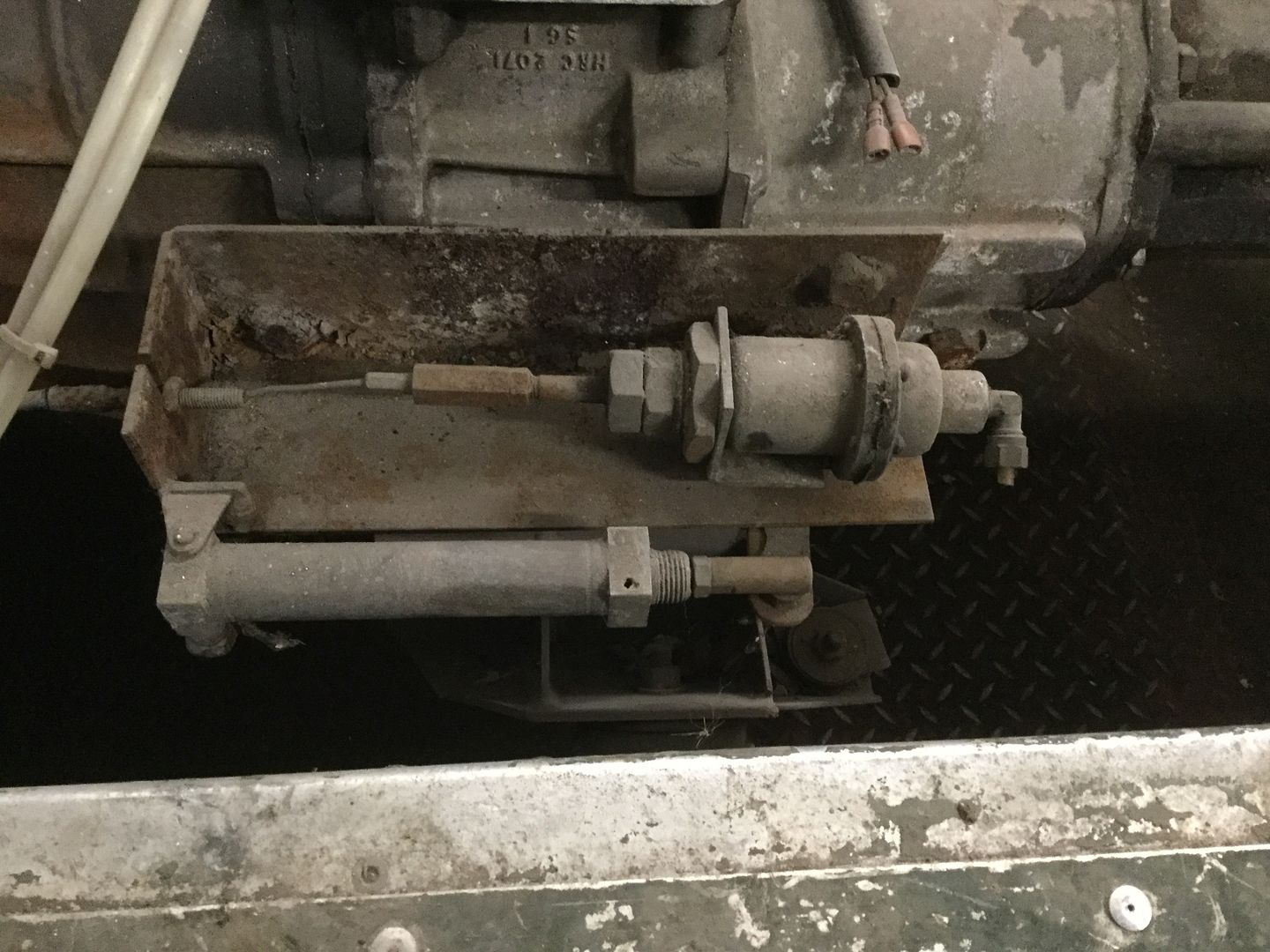

3. Fitted a PTO to the transfer box.

4. Converted to power steering.

5. Fitted a hydraulic winch in the front

6. Mounted an atlas copco screw comressor and the buisness end of a 265 amp diesel arc welder that threw a rod in the back.

7. Front panel was trashed so made a new one and riveted it on.

8.Stripped all the years of MOD paint off.

9. Fitted some comfy low squab seats.

10 . Made some rims up using laser cut centers and bought in rims, fitted gurt tyres.

Lots to do still. All the kit to finish is just thrown in the back so first job will be to decant the contents and blow the dust off

Got the 101 back to the yard, this is an ex Judge Dred landy that had one of those fiberglass body lashups you see in the film. Amazingly rust free.

Work done so far.

1.Junked the V8 petrol and four speed gearbox, fitted a 3ltr mazda/perkins with a five speed LT77 and transfer box, re configured the gear change and transfer box control levers.

2. Made up the props using wide angle UJ`s

3. Fitted a PTO to the transfer box.

4. Converted to power steering.

5. Fitted a hydraulic winch in the front

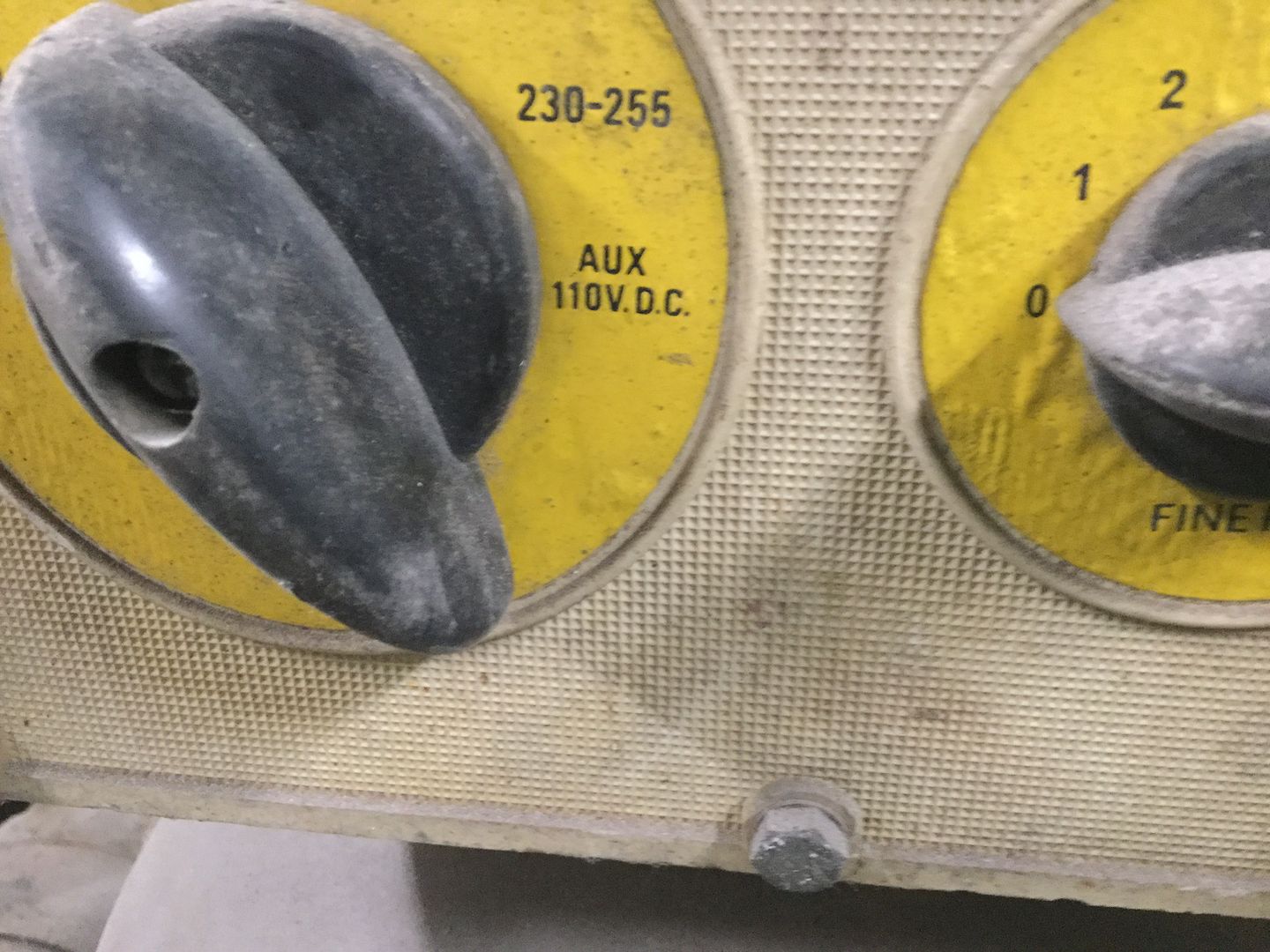

6. Mounted an atlas copco screw comressor and the buisness end of a 265 amp diesel arc welder that threw a rod in the back.

7. Front panel was trashed so made a new one and riveted it on.

8.Stripped all the years of MOD paint off.

9. Fitted some comfy low squab seats.

10 . Made some rims up using laser cut centers and bought in rims, fitted gurt tyres.

Lots to do still. All the kit to finish is just thrown in the back so first job will be to decant the contents and blow the dust off

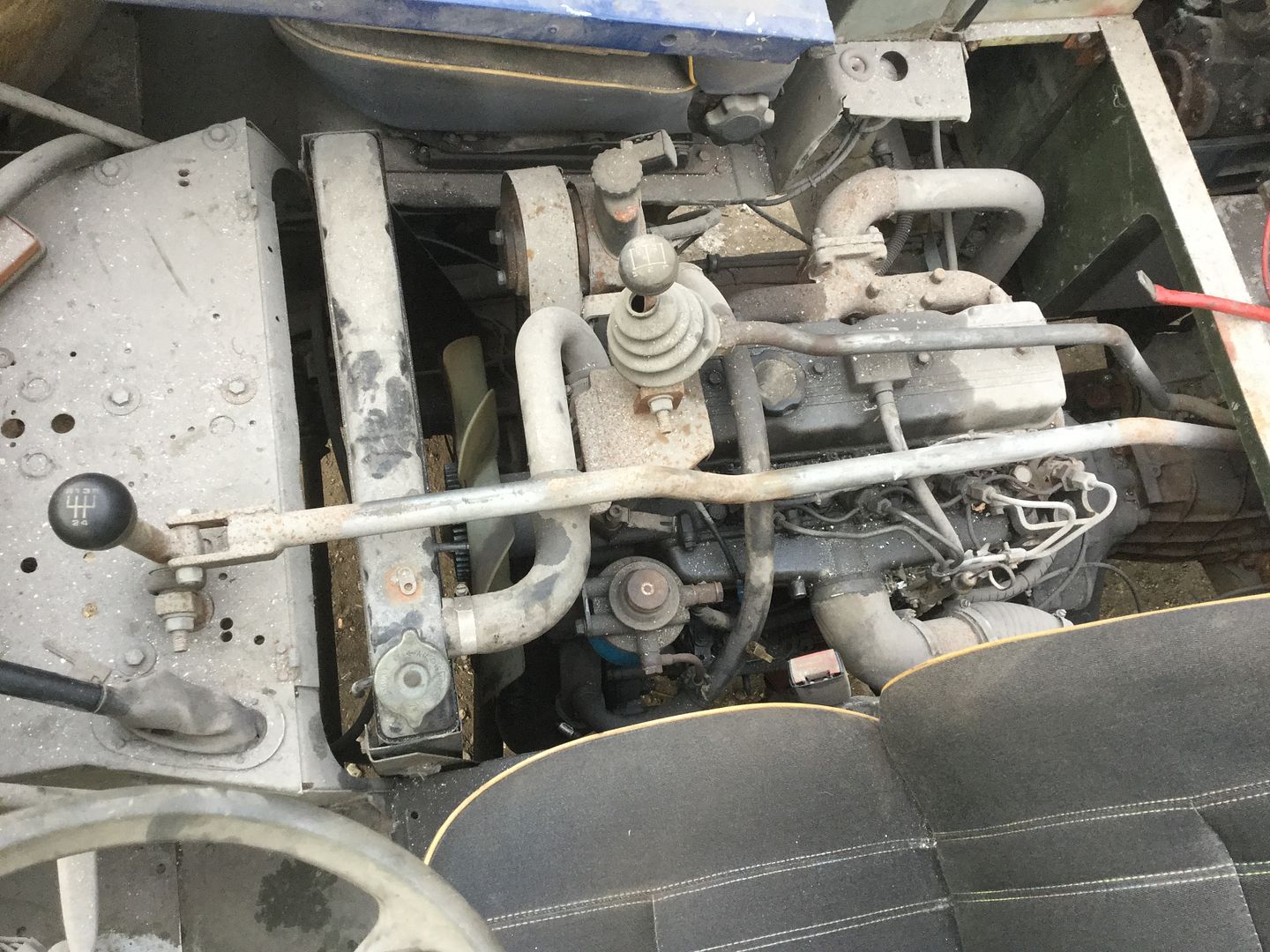

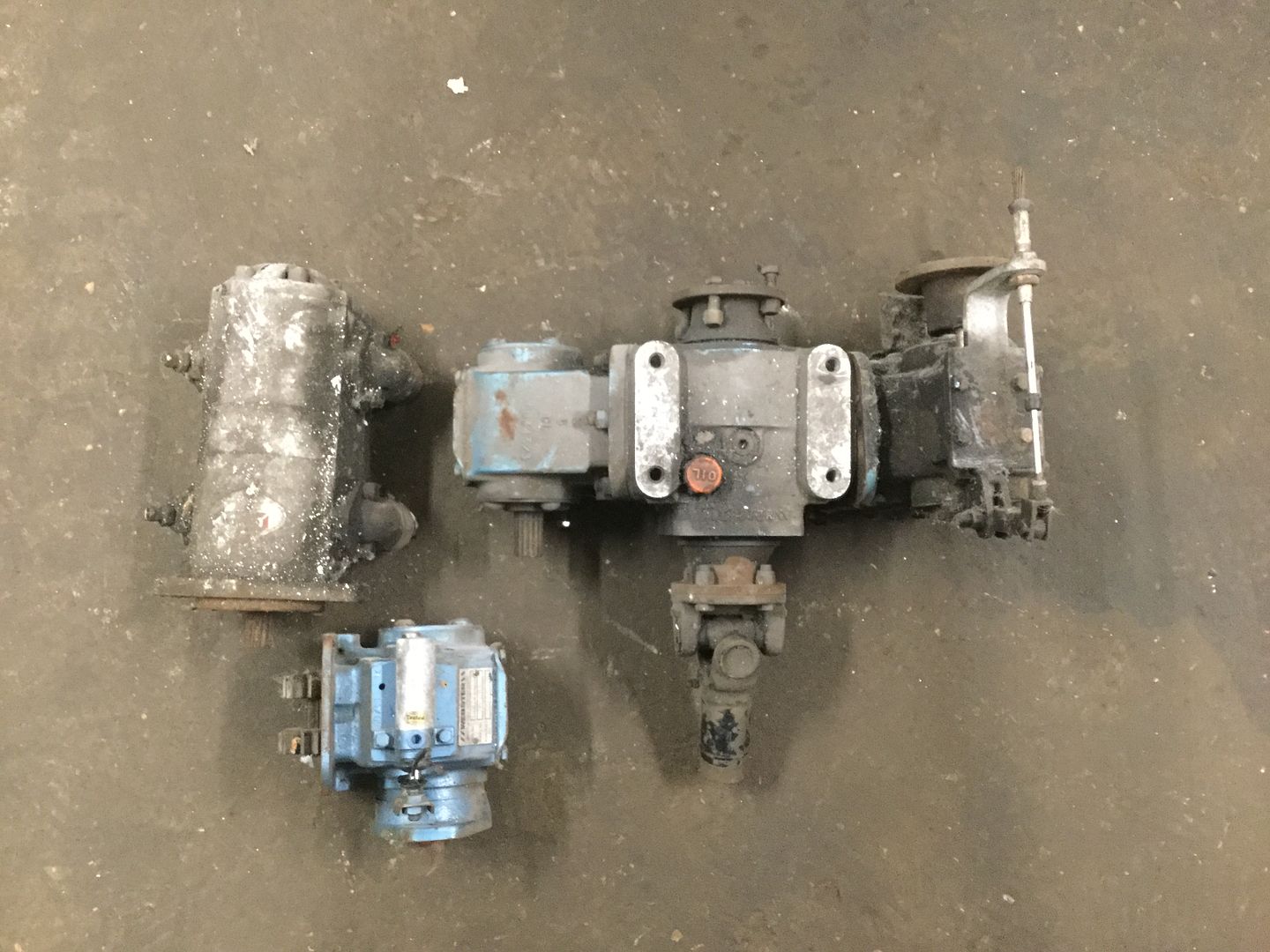

Mounts for the webster pto gear are done which leaves the short shaft from gearbox pto to splitter to make up, short shaft then to make up for the screw compressor , mount the hydraulic pump on the splitter, make up shafts/ belt drive to the welder genny.

Mounts for the webster pto gear are done which leaves the short shaft from gearbox pto to splitter to make up, short shaft then to make up for the screw compressor , mount the hydraulic pump on the splitter, make up shafts/ belt drive to the welder genny.

) couldn't you rig one up, if you can get a tachometer on the engine, or buy a cheap eBay electronic tacho and monitor the output shafts of the PTO/belt drive for the welder?

) couldn't you rig one up, if you can get a tachometer on the engine, or buy a cheap eBay electronic tacho and monitor the output shafts of the PTO/belt drive for the welder?