gaz1

Member

- Messages

- 20,535

- Location

- westyorkshire

well im posting this so you lot can have a chuckle

with thanks @MattH whos been kind enough to collect the said items for me

thankyou

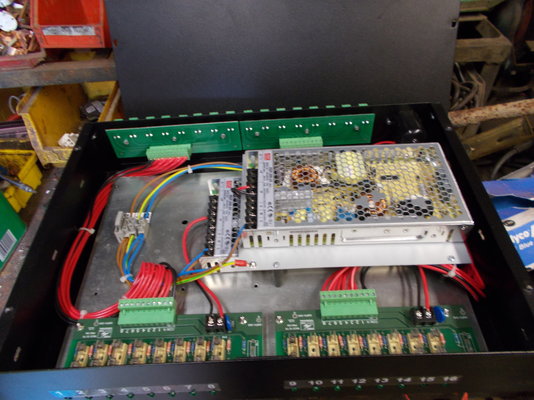

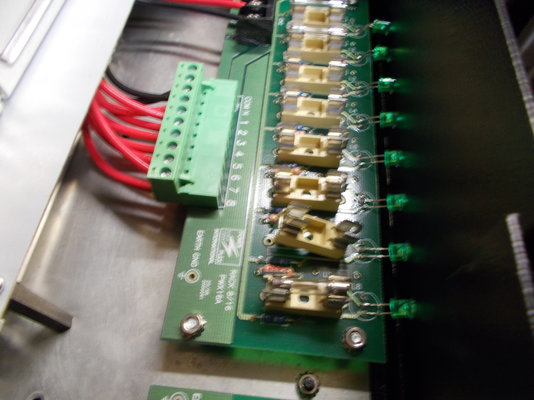

heres what they both look like at side of each other

im still sat here thinking wow I knew it was biggish but not that big to a degree it might even be over 30 KGs as im told

matt has offered a swap for it which ive excepted it as its massive

with thanks @MattH whos been kind enough to collect the said items for me

thankyou

heres what they both look like at side of each other

im still sat here thinking wow I knew it was biggish but not that big to a degree it might even be over 30 KGs as im told

matt has offered a swap for it which ive excepted it as its massive