daleyd

Member

- Messages

- 10,482

- Location

- Wrexham, North Wales

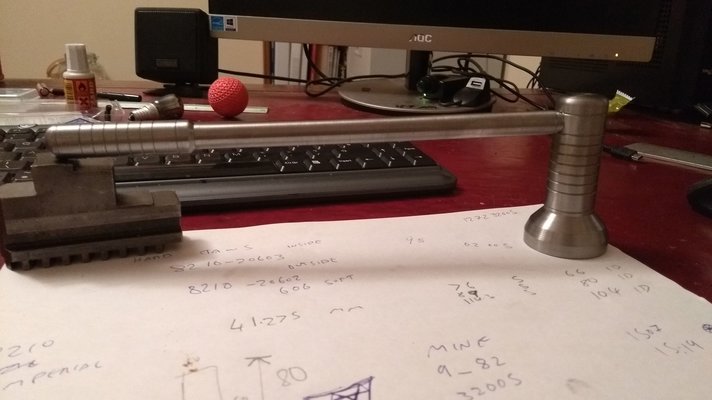

If it’s a case of scrap it because the bearings are going to cost 4K or put something in that is “good enough” for tinkering at home, then surely it’s a no brainer...Things of beauty, but in the world outside toolrooms can the mega expense truly be justified?

![IMG_20181103_220143239[1].jpg IMG_20181103_220143239[1].jpg](https://www.mig-welding.co.uk/forum/data/attachments/154/154688-1172768a13ed80b4efe15c5ab74d4021.jpg?hash=EXJ2ihPtgL)

![IMG_20181103_220201841[1].jpg IMG_20181103_220201841[1].jpg](https://www.mig-welding.co.uk/forum/data/attachments/154/154689-8855e59a9cbba5a6ad7444d8465212d2.jpg?hash=iFXlmpy7pa)