You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Workholding in hydraulic press?

- Thread starter Chris152

- Start date

8ob

Member

- Messages

- 14,304

- Location

- Nescient in the vale

I agree, if its a pig to hold in a press just drift them in/out. Its good enough for cam bearings.Waste of time using a press to remove and refit king pin bushes ! A suitable drift the diameter of the kingpin with a shoulder slightly smaller than the OD of the bush and away you go! Probably took me longer to type this than it takes to replace the bushes? You’re going to have to ream the bushes to size . I must have done dozens of A30, A35,A40 and Spridget king pins over the years and have never used a press even when working beside one. Found the best way to sort out seized trunnion pins and bushes is to fit reconditioned lower arms from the MG Owners club or similar , leave the kingpin attached to the old lower arm its all going to be replaced anyway

Bob

Yes, I hadn't thought of the pressure on the casting. The seem incredibly tight, I'll give that method a miss.I might give that suggestion a quick go - but if the bush didn't shift immediately, I've be worried about bending the upright. In that case, I'd try support the bottom one on the tube, put a bar through the upper one to press on a spacer to push the bottom out. Then flip and repeat for the other one.

Yesterday I tried both pressing it out with a drift in a vise (we have a different vise now that allowed it to sit properly between the jaws) and I tried pulling it out with a threaded bar. The drift diameter is a tad smaller than the OD of the bush so it should have worked, but I ended up breaking the vise casting and the drawing method didn't work either. I guess the drift wasn't concentric and was catching on the casting - I'll try to turn a new one today and see if that works with the draw/ threaded bar method.

daedalusminos

Member

- Messages

- 2,429

- Location

- Norwich

Safest, fastest way is a drawbar, two custom mandrels and a impact driver. Design the mandrels so they are reversible and can be used to pull the new bushes in. Grease the threads and thrust surfaces (fine pitch thread better) and the job will be done in 10mins including making the mandrels.

Eventually drew it out! To my horror I realised that, after making a new mandrel this morning to the right size and getting no further with that, the socket I was pulling it into was what was holding the bush in place, it was too small. So, two hardened M10 threaded bars later:

I think it's called learning the hard way.

Thanks for the help all.

I think it's called learning the hard way.

Thanks for the help all.

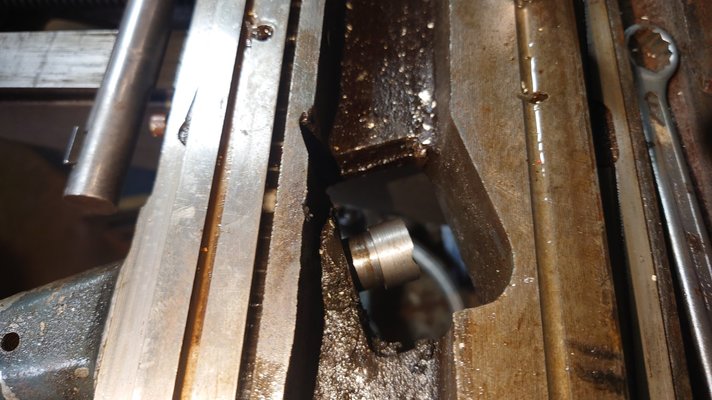

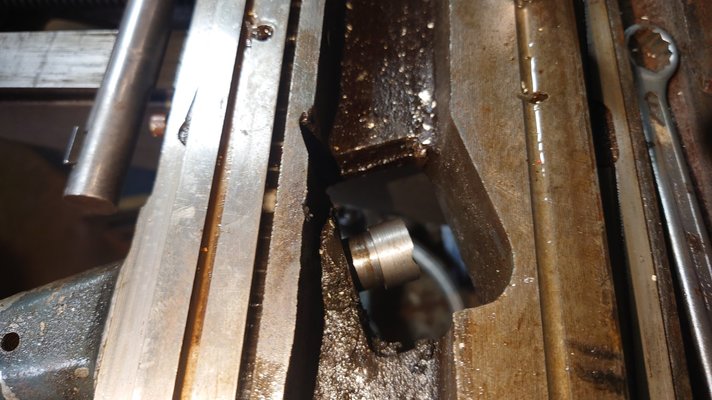

Spoke too soon - the saga continues. Fitting the new bushing, the mandrel (only about 0.5mm less diameter than the bushing) slipped inside the bushing and forced it open along the slit. I tried drawing it in but at the last, it collapsed and refused to enter the casting. It is incredibly tight, even with a breaker bar. So, I'm going to try with a wider mandrel (it doesn't need to go beyond the casting as that's where the bushing should sit). Before I trash yet another bushing, can anyone see anything that's going to fail in this setup?

Melvyn Best

Member

- Messages

- 2,003

- Location

- Cambridge

You can lead a horse to water?

Thanks Melvyn, really helpful.You can lead a horse to water?

Dcal

Forum Supporter

- Messages

- 4,077

- Location

- Antrim Northern Ireland

Not the same but similar.

I needed to change a couple of bushes in my Eagle surface grinder with very little access.

I made a mandrel and used a slide hammer to drift out the old bush and install the new. It was tight but not crazy tight but I did need to ream the bushes to size after.

The mandrel was a good fit but not so tight it would bind in the installed bush.

I'd check the id of the stub and the od of the bush before going any further.

I needed to change a couple of bushes in my Eagle surface grinder with very little access.

I made a mandrel and used a slide hammer to drift out the old bush and install the new. It was tight but not crazy tight but I did need to ream the bushes to size after.

The mandrel was a good fit but not so tight it would bind in the installed bush.

I'd check the id of the stub and the od of the bush before going any further.

Melvyn Best

Member

- Messages

- 2,003

- Location

- Cambridge

I’ve already suggested how it’s done, I’ve done dozens of them since 1967 ! up to you if you don’t take advice!Thanks Melvyn, really helpful.

Thanks Dcal. The casting measures 23.10mm, the bushing 23.17mm (after several attempts on each with the calliper). So about .0028" bigger. There's a slit in the bushing with a slight gap to close on the steel outer layer (brass/ bronze inner has none), so I guess that should compress. Does that sound about right? I'll have a go with the setup above later today, if I get a chance.Not the same but similar.

I needed to change a couple of bushes in my Eagle surface grinder with very little access.

I made a mandrel and used a slide hammer to drift out the old bush and install the new. It was tight but not crazy tight but I did need to ream the bushes to size after.

The mandrel was a good fit but not so tight it would bind in the installed bush.

I'd check the id of the stub and the od of the bush before going any further.

View attachment 452915

View attachment 452918

View attachment 452917

View attachment 452916

Your split Bush will compress as its drawn in. Your earlier attempt failed because your maderel fitted inside the Bush. As long as your new mandrel is bigger than the top of the Bush, so it can't fit inside (which it looks like it is) then your new setup should work a treat.

Go for it, what's the worst that can happen.

Go for it, what's the worst that can happen.

500e

Always buy fire insurance a flood is a hard start

- Messages

- 9,299

- Location

- South West

You polished the housing ?

Cant remember split bush or not. Can you @Melvyn Best

Gave the tools we made away 30 years ago. They did have a register that fitted into the bush but was I think 15/20 Th down on bush size it was just to hold the tool more or less central.

The hardest part usually was removing No.26 taper pin and No23Fulcrum pin, especially of they had not been greased.

The bottom No21 lower link could twist as well making the whole thing a pitta!!, we used to weld in a closing plate on the ones we rallied to stop them catching rocks and twisting

They were weekly job in the 60/70 on A30 A35 A40 Sprites and Midgets etc.

Reaming was the secret to long life, and never turn the reamer backwards

Cant remember split bush or not. Can you @Melvyn Best

Gave the tools we made away 30 years ago. They did have a register that fitted into the bush but was I think 15/20 Th down on bush size it was just to hold the tool more or less central.

The hardest part usually was removing No.26 taper pin and No23Fulcrum pin, especially of they had not been greased.

The bottom No21 lower link could twist as well making the whole thing a pitta!!, we used to weld in a closing plate on the ones we rallied to stop them catching rocks and twisting

They were weekly job in the 60/70 on A30 A35 A40 Sprites and Midgets etc.

Reaming was the secret to long life, and never turn the reamer backwards

daedalusminos

Member

- Messages

- 2,429

- Location

- Norwich

Can't you use a long piece of studding and pull them through from the outer ends?...Thanks Dcal. The casting measures 23.10mm, the bushing 23.17mm (after several attempts on each with the calliper). So about .0028" bigger. There's a slit in the bushing with a slight gap to close on the steel outer layer (brass/ bronze inner has none), so I guess that should compress. Does that sound about right? I'll have a go with the setup above later today, if I get a chance.