- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

dan.taylor.1

General Tinkererer

- Messages

- 2,786

- Location

- Kendal, Cumbria

Did you get the spindle out then?Machining should be back on the table once I get the new bearings in tomorrow.

View attachment 356603

Brad93

Member

- Messages

- 19,436

- Location

- Essex, United Kingdom

With oxyacetylene and much hammeringDid you get the spindle out then?

dan.taylor.1

General Tinkererer

- Messages

- 2,786

- Location

- Kendal, Cumbria

What was holding it, just the bearing?With oxyacetylene and much hammering

Brad93

Member

- Messages

- 19,436

- Location

- Essex, United Kingdom

The nose was threaded. Left hand thread. And not been removed in 60 yearsWhat was holding it, just the bearing?

dan.taylor.1

General Tinkererer

- Messages

- 2,786

- Location

- Kendal, Cumbria

You'd have thought a hole or 2 for a pin spanner would have been sensible/helpful!

Brad93

Member

- Messages

- 19,436

- Location

- Essex, United Kingdom

Yep. And maybe an LH stamp or something.You'd have thought a hole or 2 for a pin spanner would have been sensible/helpful!

I guess they didn't think these mills would still be running in 60+ years time.

I mean the manual is 10 pages more or less with no diagrams or parts lists. Maybe a service manual existed but they certainly wouldn't be widely available.

No, back in the day they’d have the makers version of Clive @pressbrake1 in to service it, if needed.Yep. And maybe an LH stamp or something.

I guess they didn't think these mills would still be running in 60+ years time.

I mean the manual is 10 pages more or less with no diagrams or parts lists. Maybe a service manual existed but they certainly wouldn't be widely available.

Brad93

Member

- Messages

- 19,436

- Location

- Essex, United Kingdom

No don't be silly it's fine.Take it threaded is now past tense ?

Brad93

Member

- Messages

- 19,436

- Location

- Essex, United Kingdom

Well something isn't right. Not sure if it's these dubious bearings or something hasn't gone back together right because I've got either a tonne of play or a really tight spindle, nothing inbetween.

Like an idiot I've put the whole lot back in the machine which is probably the best part of two hours work messing about trying to reconnect the poxy chain.

Like an idiot I've put the whole lot back in the machine which is probably the best part of two hours work messing about trying to reconnect the poxy chain.

Kram

Member

- Messages

- 8,381

- Location

- Sussex

Preload adjustment for spindles is an art, the second bearings are too tight fit to make it easy. I couldnt find if theres a factory process/method for it, or if it just needs more experience.

With my lathe spindle, a few on here suggested easing the fit for the rear bearing as they tend to jump from loose to too tight.

With my lathe spindle, a few on here suggested easing the fit for the rear bearing as they tend to jump from loose to too tight.

The manual for my Town Woodhouse mill suggested the preload was adjusted “a little”.Preload adjustment for spindles is an art, the second bearings are too tight fit to make it easy. I couldnt find if theres a factory process/method for it, or if it just needs more experience.

With my lathe spindle, a few on here suggested easing the fit for the rear bearing as they tend to jump from loose to too tight.

Pete.

Member

- Messages

- 15,074

- Location

- Kent, UK

Turned a couple of axles to give some podium steps at work a new lease of life. The old tube aaxles had fallen out ages ago and people stopped using them. It so happens that they are perfect for my work so it was worth the hour of turning them out of steel then oil-blackening them so they don't rust too quickly.

Rannsachair

Forum Supporter

- Messages

- 4,516

- Location

- Lochgilphead, Argyll, Republic of Scotland

Turned this tap adaptor in stainless a while ago:

now fitted, filled a gapthat allowed tap to push through worktop on daughter in laws mum's sink:

Father in law asked for some 2 penny washers:

And took a skim of the damaged anvil on my swinden and welded up and spot faced mounting feet.

now fitted, filled a gapthat allowed tap to push through worktop on daughter in laws mum's sink:

Father in law asked for some 2 penny washers:

And took a skim of the damaged anvil on my swinden and welded up and spot faced mounting feet.

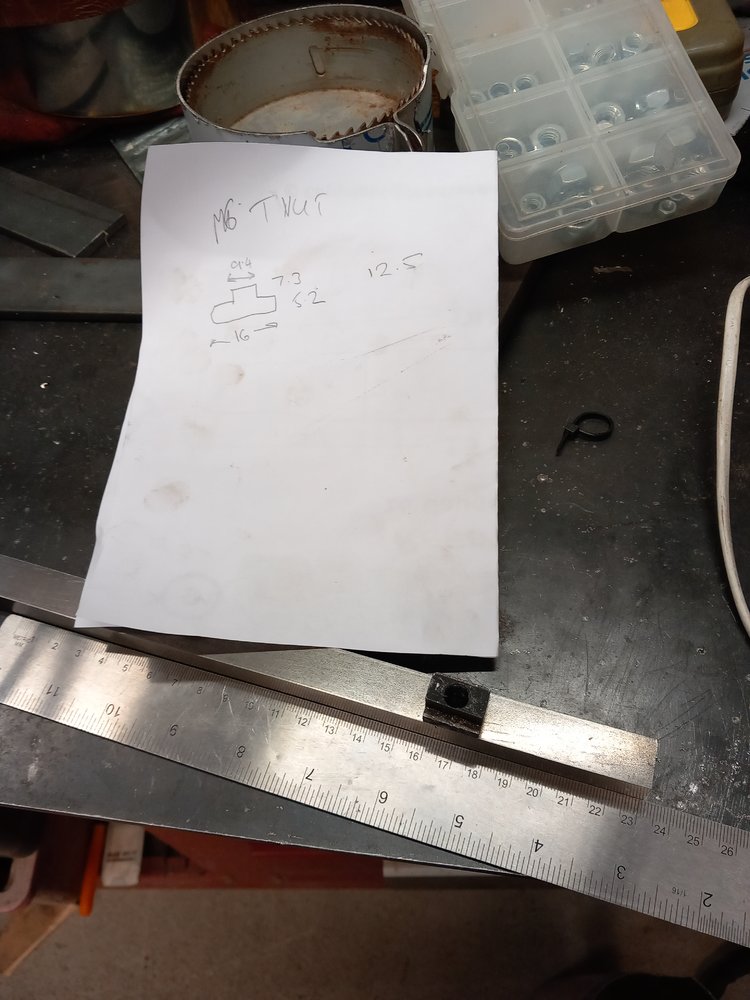

I'm having a go at making some t-nuts with an M6 metric thread. From memory, the set on my mill are nominally 3/8" top slot with a 5/16ths thread.

I want the smaller metric thread so I can mount my work using holes already found in the work piece design. It needs bolting to an adjustable angle plate. There will be a sacrificial spacer to prevent the apprentice marks.

Rough dimensions measured and rounded up as the T nuts that I have seem to be a bit on the small side. I know we don't want them getting stuck, but they seem a rather slack fit.

I've bought some 16mm square bar so my bottom dimension is already done. The black t-nut sat on the bar is a shoddy Chinese one that I'm trying to replicate.

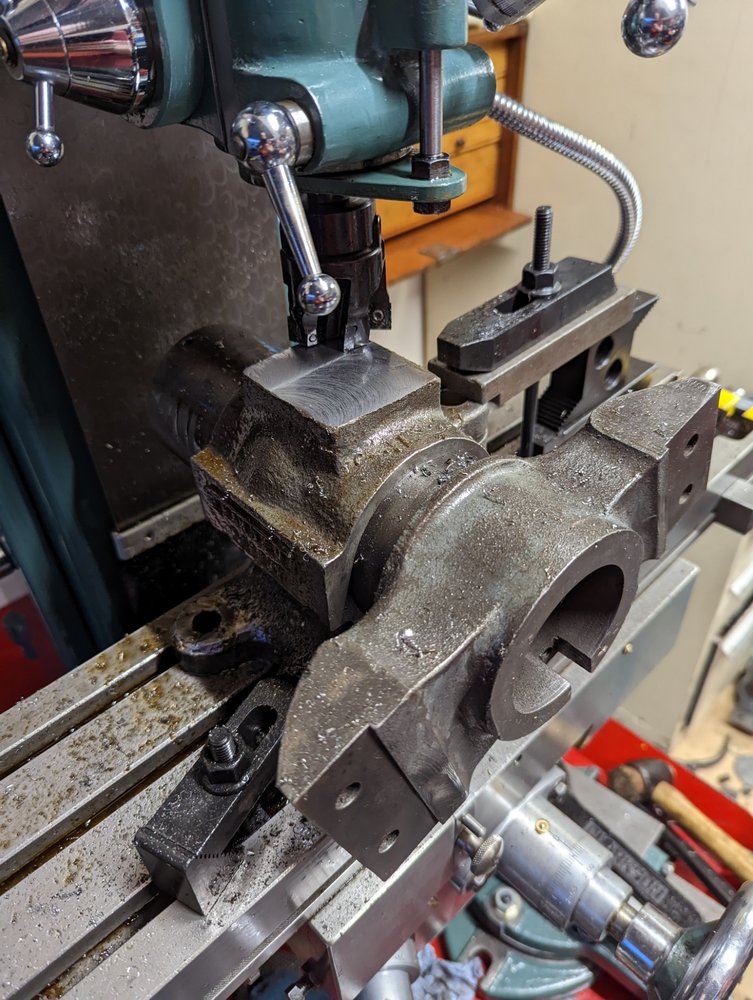

Bar set up on the mill. There's a lot of spare material at the top that I used to finesse my cutting in from the side. The top 3.5mm will be removed so if I cut too far towards the centre it didn't matter. I used an edge finder and my DRO but still needed to make adjustments. Possibly a worn end mill or flex in my shoddy set up. I got it dialled in before I ran out of depth.

A quick comparison as I go along. Getting there. The T-nuts are a slack fit so as long mine aren't any smaller there is plenty of leeway.

I've milled enough material to make three. I only need two. Stick out from the vice was bad enough without trying for more. This was a fair bit of work for me. I was taking a half mm depth of cut over 3.3mm wide. Lots of passes. A bigger machine would make short work of this, but it's a bit of a slog on a small mill.

Just need to cut in the bandsaw, drill and tap.

I want the smaller metric thread so I can mount my work using holes already found in the work piece design. It needs bolting to an adjustable angle plate. There will be a sacrificial spacer to prevent the apprentice marks.

Rough dimensions measured and rounded up as the T nuts that I have seem to be a bit on the small side. I know we don't want them getting stuck, but they seem a rather slack fit.

I've bought some 16mm square bar so my bottom dimension is already done. The black t-nut sat on the bar is a shoddy Chinese one that I'm trying to replicate.

Bar set up on the mill. There's a lot of spare material at the top that I used to finesse my cutting in from the side. The top 3.5mm will be removed so if I cut too far towards the centre it didn't matter. I used an edge finder and my DRO but still needed to make adjustments. Possibly a worn end mill or flex in my shoddy set up. I got it dialled in before I ran out of depth.

A quick comparison as I go along. Getting there. The T-nuts are a slack fit so as long mine aren't any smaller there is plenty of leeway.

I've milled enough material to make three. I only need two. Stick out from the vice was bad enough without trying for more. This was a fair bit of work for me. I was taking a half mm depth of cut over 3.3mm wide. Lots of passes. A bigger machine would make short work of this, but it's a bit of a slog on a small mill.

Just need to cut in the bandsaw, drill and tap.