jordhandson

Member

- Messages

- 1,430

- Location

- Dorset

Love it. Did you find the pulley quite gummy to machine and prone to surface tearing?

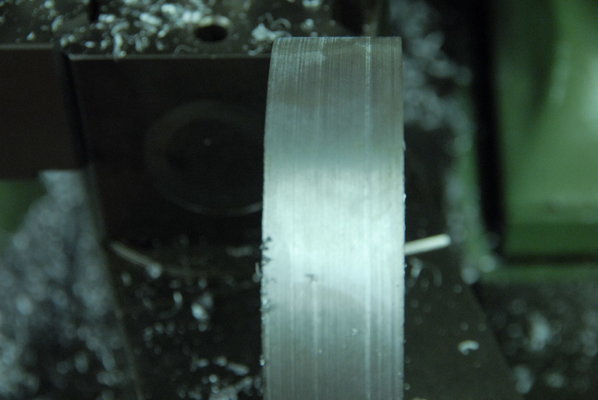

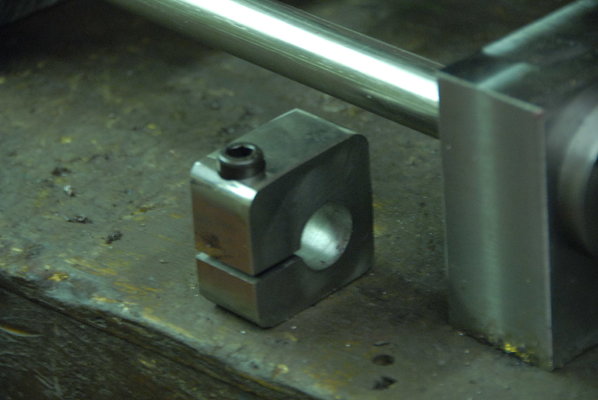

Hi Pete, as this is the first time turning ally, I don’t think I am the right person to say whether it was gummy or not, it produced some good swarf,

I don’t know if you can tell by that, the finish wasn't to bad,

probably the feed was a bit fast, it sanded well. I have only turned steel, and after trying to turn that piece of ram steel, last week, this ally block was like cutting through cheese.

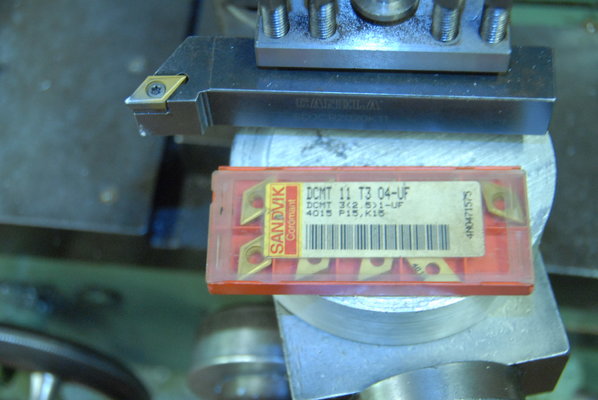

Thinking about it, I did have to clean the insert off a couple of times, so I suppose you could say gummy is a good description. I use this tool and new inserts.

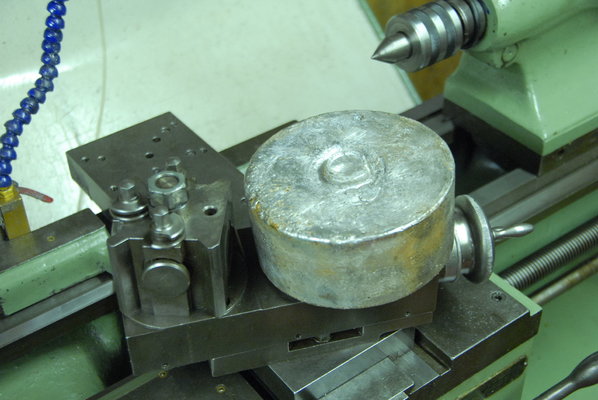

When turning it I did find a bit of a hole in the ally block luckily it stopped before the part I needed.

This happened I think has something to do with the gassing, I will need to see a few more melting videos, to see where I went wrong, probably timing. I have a bigger lump to turn as well,

I am hoping there are no holes in it inside, I wont know till I turn it, but heyho still a lot to learn.

Cheers

Jord

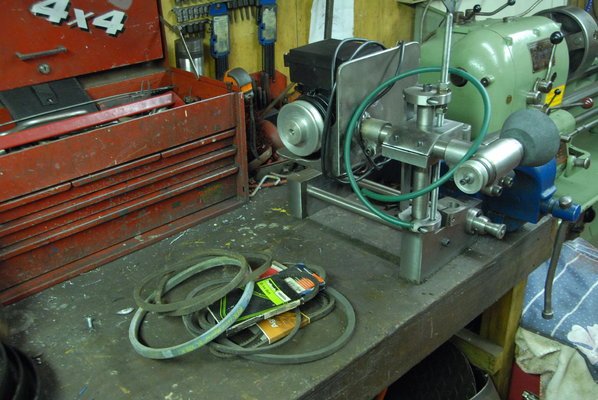

Noted Gaz, from what I have seen the rpm is normally specified on the grinding wheel label so that shouldn't be to much of a problem.

Noted Gaz, from what I have seen the rpm is normally specified on the grinding wheel label so that shouldn't be to much of a problem. straight wheels, bowl wheels, cup wheels, then there’s the abrasion, silicon wheels, diamond wheels, grey wheels white wheels even pink wheels,

straight wheels, bowl wheels, cup wheels, then there’s the abrasion, silicon wheels, diamond wheels, grey wheels white wheels even pink wheels,  the list and shape and colour seams endless let alone the git then, there’s the quality factor is one better than the next wow, talk about a head duck

the list and shape and colour seams endless let alone the git then, there’s the quality factor is one better than the next wow, talk about a head duck .

. and being in a large family I can drop a few hints regarding grinding wheels

and being in a large family I can drop a few hints regarding grinding wheels  ha ha.

ha ha. Your gonna have to help me out here, press

Your gonna have to help me out here, press  one grinding wheel

one grinding wheel