Hello everyone, I have been having issues with my mig welder SEALEY SUPERMIG 180 after I installed a EURO torch MB25AK.

I noticed that since I converted it to a euro torch, it seems to produce a lot of spatter and the penetration even at max power is not as good as it was before with the original torch.

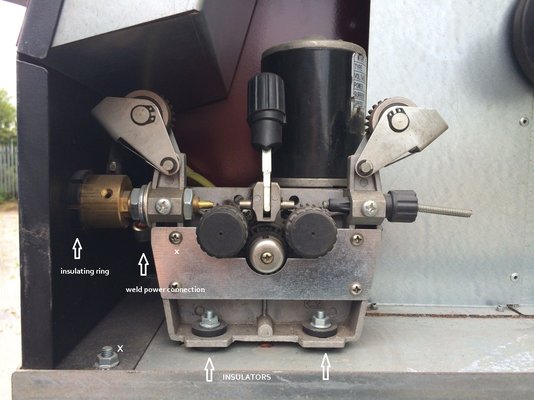

I checked all the connections and they don't seem to be the problem. I changed the earth clamp with a proper copper one (see below clamp I installed)

I really don't know why is behaving like this. So, I was wondering if anyone has any suggestions having experienced something similar after a euro torch conversion?

Thanks

I noticed that since I converted it to a euro torch, it seems to produce a lot of spatter and the penetration even at max power is not as good as it was before with the original torch.

I checked all the connections and they don't seem to be the problem. I changed the earth clamp with a proper copper one (see below clamp I installed)

I really don't know why is behaving like this. So, I was wondering if anyone has any suggestions having experienced something similar after a euro torch conversion?

Thanks