Well I think I saw a few pics of this on the Vxon forum or other, certainly looks like it, then I got a bit upset as i couldn't see what came next, it's nice too see what came after, and it's certainly nice to see someone take the time and patience to not only share with those of us who have yet to try this but also to be able to see the standard of work I am seeing from a novice. I often think that those who can't do it or are to scared to try often denounce the work through their ignorance of what is actually involved and the sheer amount of stress it puts on those that do, as well as through what I perceive as their own "wishfull thinking" as to their own hopefull abilities.

Those who have done this many times may look and see what they have already gone through but have in the relativity of time caused them to forget how daunting it is and therfore criticise out of superiority, I find it most obnoxious when someone who feels such superiority due to their own experience mocks those who are just starting, nice to see that not happening here.

I remember welding up mini sills many many years ago with an arc welder set to max amperage and a rod the size of a large roundheaded nail!! and wondering why the sills disappeared in huge blobs onto the floor, I swore then after being burned and doing the indian war dance to the jokes of the neighbours many times I would never weld again, how wrong I was, its in the blood and just keeps dragging you back to itself.

Well done that man for doing the job you have. If the forum had a prize for best newbie wip I would most certainly vote for this.

Those who have done this many times may look and see what they have already gone through but have in the relativity of time caused them to forget how daunting it is and therfore criticise out of superiority, I find it most obnoxious when someone who feels such superiority due to their own experience mocks those who are just starting, nice to see that not happening here.

I remember welding up mini sills many many years ago with an arc welder set to max amperage and a rod the size of a large roundheaded nail!! and wondering why the sills disappeared in huge blobs onto the floor, I swore then after being burned and doing the indian war dance to the jokes of the neighbours many times I would never weld again, how wrong I was, its in the blood and just keeps dragging you back to itself.

Well done that man for doing the job you have. If the forum had a prize for best newbie wip I would most certainly vote for this.

As you say, I did post a few pictures on the Nissan Owners site but I think it may have been a case of pearls before swine

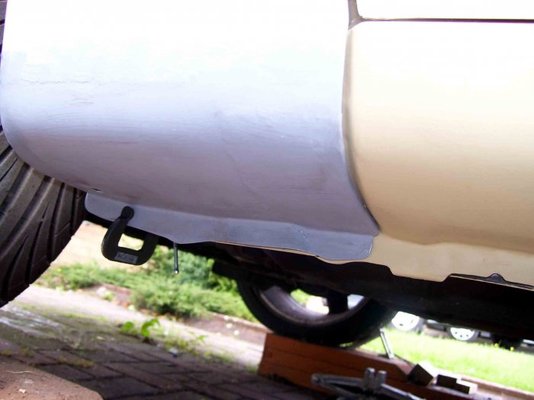

As you say, I did post a few pictures on the Nissan Owners site but I think it may have been a case of pearls before swine with regards to welding so I switched to this site for much needed help and advice so as to achieve what I have to date. I have posted a few pictures of my latest repairs.

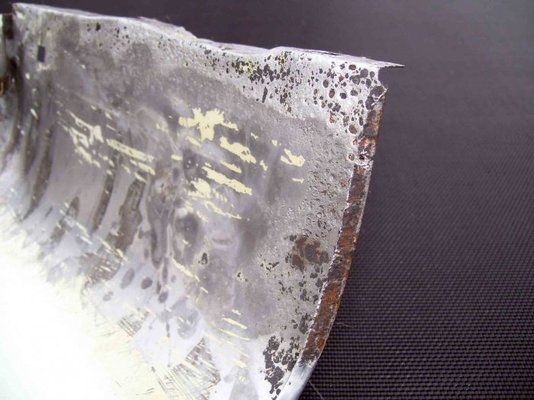

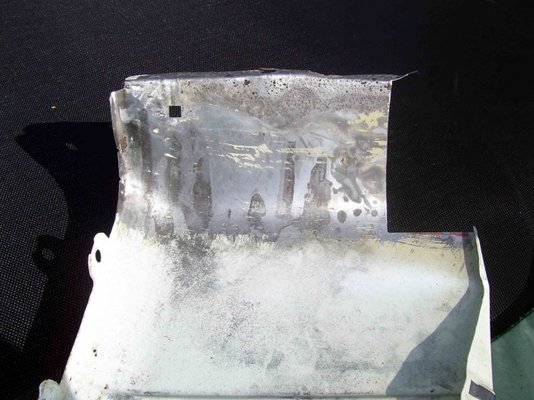

with regards to welding so I switched to this site for much needed help and advice so as to achieve what I have to date. I have posted a few pictures of my latest repairs. However, I feel I need to apologise for missing out some of the intermediate photo's showing some of the problems I encountered along the way.

However, I feel I need to apologise for missing out some of the intermediate photo's showing some of the problems I encountered along the way. The pictures show the beginning and the end result but not the changes in technique i had to adopt along the way so as to combat the overhead welding issues. The 2 main issues i felt contributed were, (1) Preparation in awkward places is imperative so as to minimise gases,

The pictures show the beginning and the end result but not the changes in technique i had to adopt along the way so as to combat the overhead welding issues. The 2 main issues i felt contributed were, (1) Preparation in awkward places is imperative so as to minimise gases, This did bring it's own set of problems with regards to torch speed but once I got the hang of not burning through (which i did a lot of)

This did bring it's own set of problems with regards to torch speed but once I got the hang of not burning through (which i did a lot of)