You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

MattF

Forum Supporter

- Messages

- 18,590

- Location

- South Yorkshire

There are four now! Edited as I don't think Badabec was talking about my bushes glowing!View attachment 501109

A glowing bush. Now there's a thought.

RWD3M

Forum Supporter

- Messages

- 3,962

- Location

- Wiltshire, UK

Ginger Mi.... sorryOh dear.

RWD3M

Forum Supporter

- Messages

- 3,962

- Location

- Wiltshire, UK

Dozzer

Forum Supporter

- Messages

- 791

- Location

- Essex/Suffolk border

how do you know he has, you been looking!Ginger Mi.... sorry

oldbikedavey

Member

- Messages

- 2,019

- Location

- London, England

Considerable inroads on the functionality of the Holdridge Radii Turning Attachment.

Needs a bit of centre height reduction , but as it now is bolted down on 5/16" raising plates on the Colchester compound slide, that's an 'easy' wangle with some 1/4" gauge plate substitutes..

Did a first cut on a chunk of aluminium this afternoon, and it certainly works beautifully well....

Proper pleased with that one.....

Needs a bit of centre height reduction , but as it now is bolted down on 5/16" raising plates on the Colchester compound slide, that's an 'easy' wangle with some 1/4" gauge plate substitutes..

Did a first cut on a chunk of aluminium this afternoon, and it certainly works beautifully well....

Proper pleased with that one.....

Blue Chips

Forum Supporter

- Messages

- 759

- Location

- Maine, USA

I just finished installing my full-rise scissor car lift in the new garage. Parts of the user manual that came with the lift were almost undecipherable, but the seller was very helpful and promptly answered my questions about all of the specs that I needed.

It's working great, and the quality appears to be quite decent. It’s a full-rise lift, which will allow me to stand up under my spouse's car, as well as my 1954 Dodge M37 (IF the top and windshield are folded down). With a taller vehicle like my F-150, I won’t be able to lift it quite all the way up, so I’ll have to stoop a bit when working under it, or else sit on a tall stool. The garage ceiling height is 11 feet, and the top of the lift platform will rise up to about 6 feet above the floor, leaving around 5 feet to the ceiling. The ramps at the end of the platforms can be locked in a flat position to extend the platform surface.

The yellow air compressor in the photo is doing temporary duty. I'm looking for a small wall-mount compressor to save floor space. An air compressor is only used to operate the safety pawls on the lift. The hydraulic pump for the lift is inside the control console. My other garage (serving as my shop) has a 60-gallon plumbed-in compressor, and I might eventually install such a unit in the new garage at some point, but other things are higher on the to-do list.

I’m hoping to take my M37 out of the overpriced storage unit and bring it home within the next week or two. I'm looking forward to doing the chassis work on the lift instead of lying on my back or bending over.

It's working great, and the quality appears to be quite decent. It’s a full-rise lift, which will allow me to stand up under my spouse's car, as well as my 1954 Dodge M37 (IF the top and windshield are folded down). With a taller vehicle like my F-150, I won’t be able to lift it quite all the way up, so I’ll have to stoop a bit when working under it, or else sit on a tall stool. The garage ceiling height is 11 feet, and the top of the lift platform will rise up to about 6 feet above the floor, leaving around 5 feet to the ceiling. The ramps at the end of the platforms can be locked in a flat position to extend the platform surface.

The yellow air compressor in the photo is doing temporary duty. I'm looking for a small wall-mount compressor to save floor space. An air compressor is only used to operate the safety pawls on the lift. The hydraulic pump for the lift is inside the control console. My other garage (serving as my shop) has a 60-gallon plumbed-in compressor, and I might eventually install such a unit in the new garage at some point, but other things are higher on the to-do list.

I’m hoping to take my M37 out of the overpriced storage unit and bring it home within the next week or two. I'm looking forward to doing the chassis work on the lift instead of lying on my back or bending over.

Last edited:

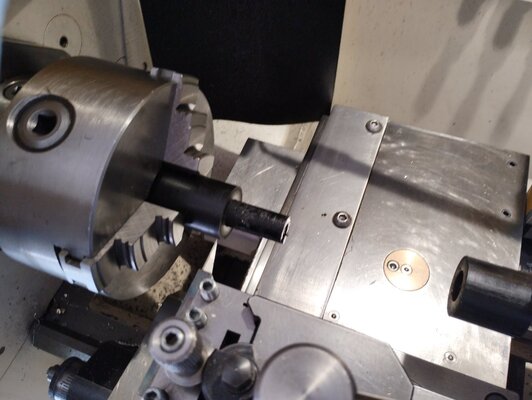

Give the boring job to the lazy guy and he'll find the easiest way

Since this Chinese lathe is pretty floppy I'm able to use that flaw so I can part the thread off flush without it taking the whole face off because the whole thing flexes under load when using the sharp taper inserts at speed with the drill.

Got the whole bag to do but it's certainly quick enough with the radio on.

Since this Chinese lathe is pretty floppy I'm able to use that flaw so I can part the thread off flush without it taking the whole face off because the whole thing flexes under load when using the sharp taper inserts at speed with the drill.

Got the whole bag to do but it's certainly quick enough with the radio on.

Because that's the only way I could get these magnetic 8x6mm straight knurled cylinders in a cost effective manner, custom ones would probably be 10x more and take longer than an afternoon at the lathe.Why did you order threaded thumbscrews if you don't want the threads?

It's m3x5mm so takes no effort to quickly remove, I'm processing one thumbscrew every 10-15s depending on how good the song playing is

sako243

Member

- Messages

- 4,449

- Location

- My mansion in Wales

I made a big bit of steel from, I think it was @hotponyshoes, into some smaller bits.

Then turned bits of it into swarf...

Then used one of @8ob's freebies to start boring out the centre. This piloted MT2 drill was beautiful at taking a chunk out the centre.

Next issue is how to fit this big 44.4mm drill bit which is possibly a sort of MT4 into an MT3 tailstock... Too big to fit down the bore of the lathe and can't hold it nicely to turn down the shank to MT3.

Perhaps should just sort out a decent boring bar. The tooling I have so far is much too big. Will have to have a scavenge to see if there's something I can grind down from the treasures Bob gave me.

Then turned bits of it into swarf...

Then used one of @8ob's freebies to start boring out the centre. This piloted MT2 drill was beautiful at taking a chunk out the centre.

Next issue is how to fit this big 44.4mm drill bit which is possibly a sort of MT4 into an MT3 tailstock... Too big to fit down the bore of the lathe and can't hold it nicely to turn down the shank to MT3.

Perhaps should just sort out a decent boring bar. The tooling I have so far is much too big. Will have to have a scavenge to see if there's something I can grind down from the treasures Bob gave me.

Kram

Member

- Messages

- 8,478

- Location

- Sussex

Weld up a mt4 adaptor to a spare toolpost holder.Next issue is how to fit this big 44.4mm drill bit which is possibly a sort of MT4 into an MT3 tailstock... Too big to fit down the bore of the lathe and can't hold it nicely to turn down the shank to MT3.

sako243

Member

- Messages

- 4,449

- Location

- My mansion in Wales

What spare tool post holders...Weld up a mt4 adaptor to a spare toolpost holder.

I'm going to see if I can chuck it up in the 4 jaw when that job comes out of it and turn the shank down to an MT3.

I'd be more worried about it overloading the tailstock. How about finding a cheaper version of this.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,650

- Location

- Keeler crater

Memmeddu

Member

- Messages

- 5,820

- Location

- Italia Sardegna

Ok after having understood that it's time turn something myself and upload over here ....

Too many lathe jobs uploaded in these days over here.

Here's what I did today

Painted spare rail covers and an angled grip.

Blued screws and springs but unfortunately no pictures of them because I was in a hurry.

Anyways I've used the rust blueing method started from them being already little bit rusty and believe it or not I've just cleaned, boiled them in water and applied little bit of WD-40

We are talking about the grip and cover black parts they came out almost perfect. can't wait to actually blue something bigger from a polished and buffed surface to see the results.

Anyways installed the painted parts on the ICS M4A1 and now starts to look good.

I'll probably end up swapping the grip on the lower for a Magpul replica and I'll seek for another stock to paint it in the same colour of the front parts.

Yes I know they already sell stocks of the right colour but I want another one identical to this because it has an hinged buttstock plate and keeps the battery well protected inside the tube

Too many lathe jobs uploaded in these days over here.

Here's what I did today

Painted spare rail covers and an angled grip.

Blued screws and springs but unfortunately no pictures of them because I was in a hurry.

Anyways I've used the rust blueing method started from them being already little bit rusty and believe it or not I've just cleaned, boiled them in water and applied little bit of WD-40

We are talking about the grip and cover black parts they came out almost perfect. can't wait to actually blue something bigger from a polished and buffed surface to see the results.

Anyways installed the painted parts on the ICS M4A1 and now starts to look good.

I'll probably end up swapping the grip on the lower for a Magpul replica and I'll seek for another stock to paint it in the same colour of the front parts.

Yes I know they already sell stocks of the right colour but I want another one identical to this because it has an hinged buttstock plate and keeps the battery well protected inside the tube

sako243

Member

- Messages

- 4,449

- Location

- My mansion in Wales

Well a little bit more bored out on the bracket and the bush is a very nice tight slip fit.

And now the 4 jaw has been freed up I've found that it's big enough to get a decent hold on the drill. Just need to source an MT3 live centre to support the other end and I should be able to turn down the taper on the big drill.

And now the 4 jaw has been freed up I've found that it's big enough to get a decent hold on the drill. Just need to source an MT3 live centre to support the other end and I should be able to turn down the taper on the big drill.