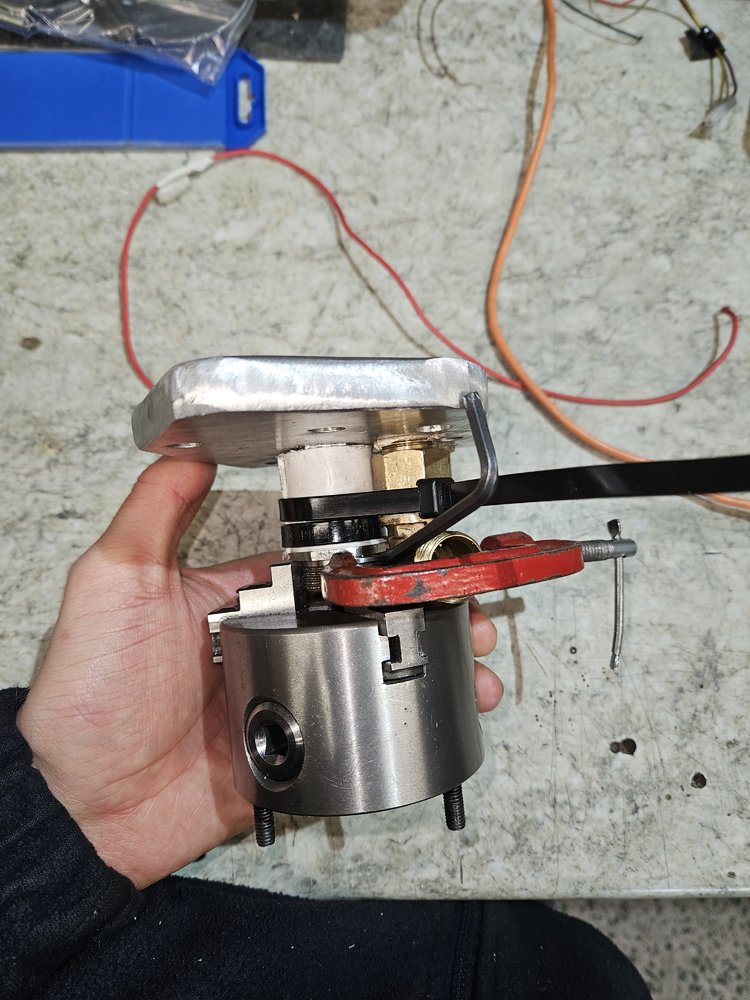

Before you have a heart attack, it's not going on the lathe

So after dropping a nice bit of oil on the floor as gasket blew out after I blocked the pump outlet to see if the Bypass spring and channel would work I realized the channel is too small for the flow and since I cannot be bothered breaking the loctite between the brass and aluminium I needed a way to clamp it roughly in the original position how I first milled the slot which resulted in this tomfoolery...

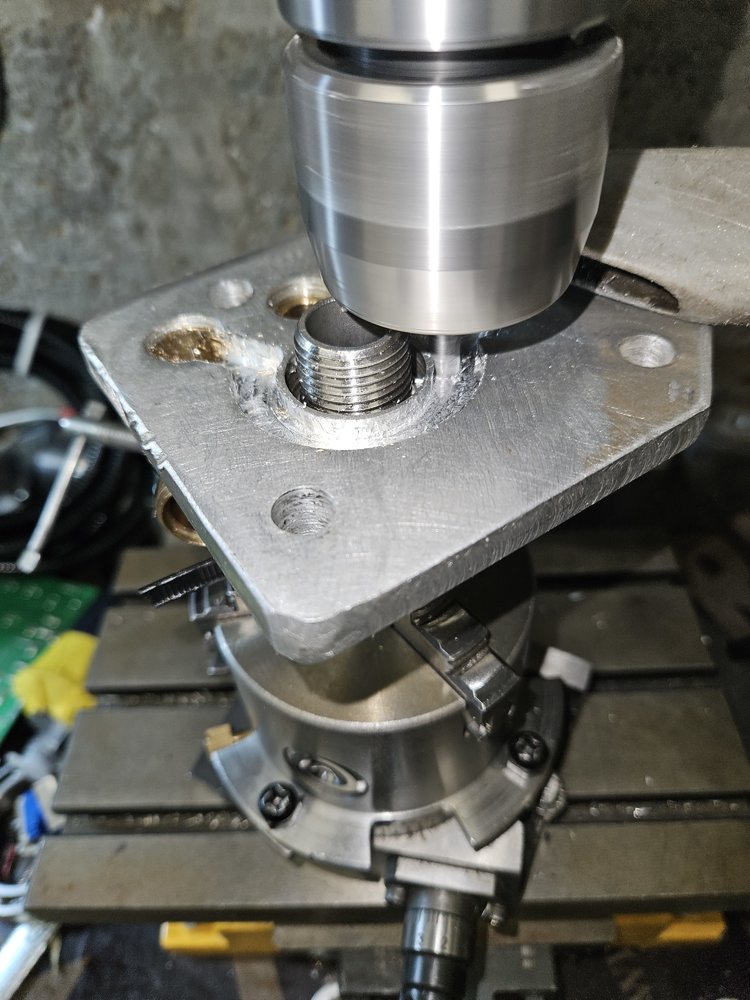

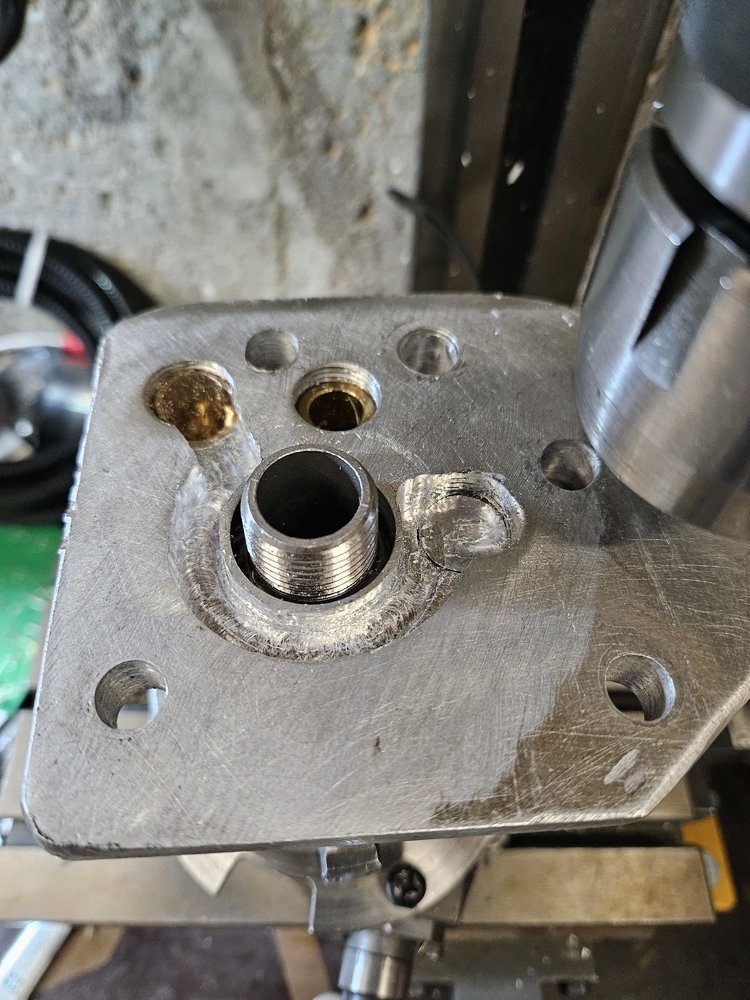

Surprisingly it seems to work quite well a little bit chatter but a lot easier than dremeling lol. It comprises of a random 1" air fitting which happens to fit perfectly in the hole with a PVC pipe sleeve to act as a spacer held securely by the short zip tie with the aluminium slid onto the air fitting and secured by clamping one of the brass fittings against a jaw with an allen key for spacing resulting in the plate being parallel to the chuck

So after dropping a nice bit of oil on the floor as gasket blew out after I blocked the pump outlet to see if the Bypass spring and channel would work I realized the channel is too small for the flow and since I cannot be bothered breaking the loctite between the brass and aluminium I needed a way to clamp it roughly in the original position how I first milled the slot which resulted in this tomfoolery...

Surprisingly it seems to work quite well a little bit chatter but a lot easier than dremeling lol. It comprises of a random 1" air fitting which happens to fit perfectly in the hole with a PVC pipe sleeve to act as a spacer held securely by the short zip tie with the aluminium slid onto the air fitting and secured by clamping one of the brass fittings against a jaw with an allen key for spacing resulting in the plate being parallel to the chuck

Last edited:

Let us know how it goes with the cold wire feeding.

Let us know how it goes with the cold wire feeding.