The (in)famous hay rake (https://www.mig-welding.co.uk/forum/threads/stuff-you-have-made-today.67127/page-646#post-1685885) has done a couple of seasons, but the PTO shaft expired with prejudice recently, when a universal joint gave up. It has seen a lot of life in the past. One of the tine holders that hold the spring tines also fell off from a combination of fatigue and rust, and some of the return springs that lift the tines up have broken.

Got another PTO and pulled the broken tine holder off and the ones with the broken spring. There is a plastic bush that had flogged out, and the tine holder shaft has severely worn and bent. I priced up some new ones - $NZ27.50 each = 13.50 pounds! I thought I ordered a replacement for the broken tine holder but forgot to have it in the shopping cart on the online order.

Looking at tine holders on the weekend, and the condition of the others, there was no way I was paying for 20 new ones so it was time to fire up the forge. They are a L shape, with a 16mm shaft with a bend in the end. The bend matches a curved piece of flat that matches the curve of the tine coil spring. This piece also has a flat area for the tines to bolt onto and they are welded together at an angle.

Bars in the gas forge

View attachment 368694

Offset the end and form a curve over the horn of the anvil

View attachment 368697View attachment 368696

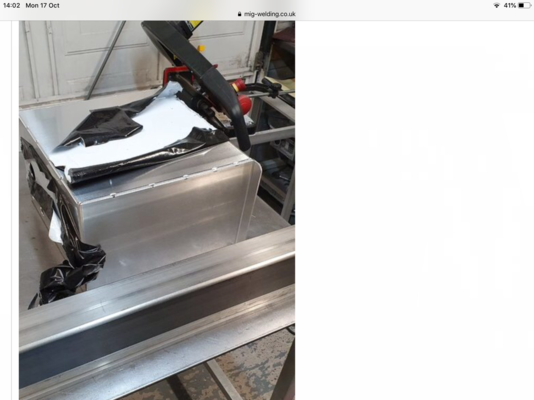

Curve the flat bar

View attachment 368698

Drill the bolt hole and use a punch with a pilot to form the flat area

View attachment 368699

Made a scratch built jig using the existing tine and guesswork for the dimensions

View attachment 368700

Drill another hole for a roll pin that anchors one end of a return spring, slop paint onto it and bolt in place. Only 19 more to go

View attachment 368701View attachment 368702

I wish I had a 3D printer, as the plastic bushes are expensive for what they are and lightweight, and i am sure I could 3D print a better one for next to nothing.

Is that a Haybob by any chance?

How do you complete the welding once the foam block is in place? Filled with liquid? Surely that would take heat away from the weld?

How do you complete the welding once the foam block is in place? Filled with liquid? Surely that would take heat away from the weld?