henry Kadzielski

Member

- Messages

- 1,209

- Location

- Australia Wollongong

My contribution. Nitrogen as a result of no oxidizing gas will leave a better edge finish on stainless steel and alloy.

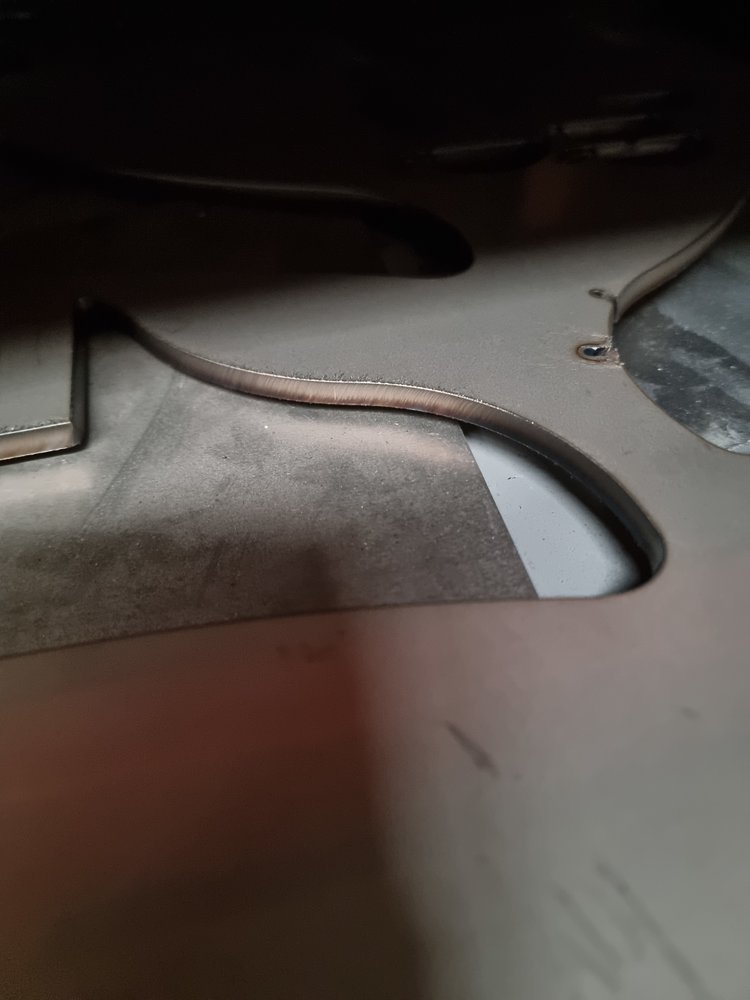

First photo is a closeup of stainless 316 and this is the scrap section

As all can see there is no burnt sugared section on the cut edge. The edge is smooth and shiny.

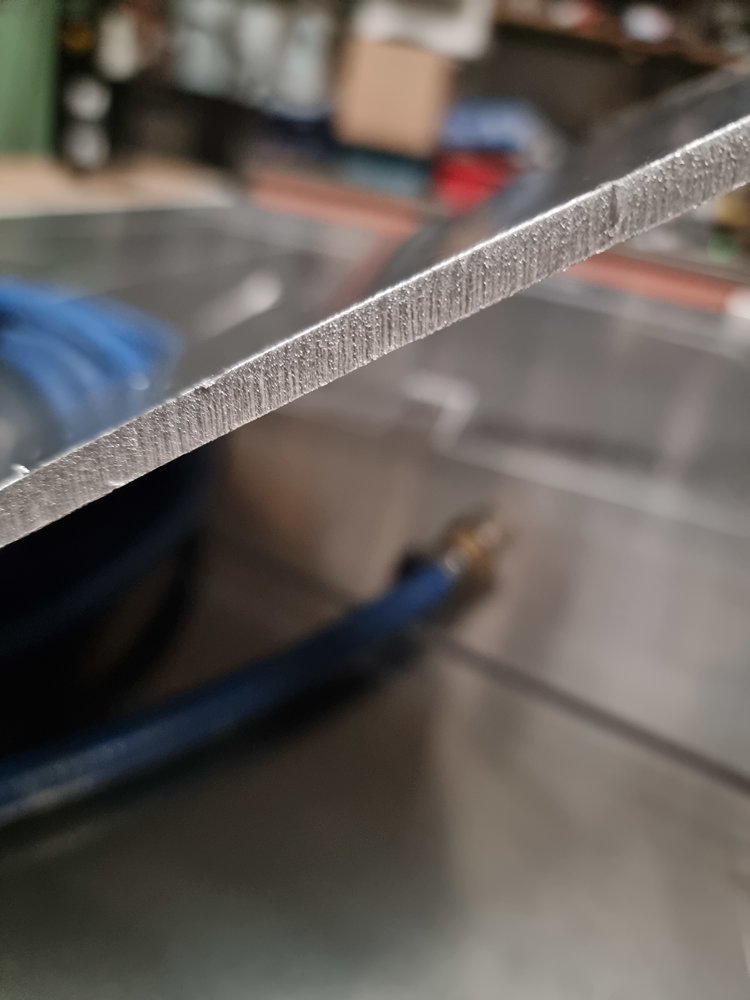

Even though the alli doesn't look like it, it is very much smoother and almost shiny like on the cut edge. The dross is less and the fume generated during cutting is less.

Now, are there other ways to achieve this, well yes, however this is what I have done to suit me. I wanted primarily to have a better edge when cutting stainless and this is what I have achieved, the alli was a bonus. I tried this a long time ago using a nitrogen bottle, yes it worked but consumed 'very much' nitrogen so I got a nitrogen generator. Problem solved. Also to note that we are cutting stainless at about 80% of the compressed air cut speed. With no oxygen there is no exothermic reaction 'thermal oxidation which is why you get that sugary burnt look' it is purely cut by the thermal temperature of the plasma flame. Alli on the other hand there is no speed change from the book spec. My two cents worth

Good afternoon @Hood. There has been talk and some vids a while ago about submersing (to what extent I don't know) material under the water and cutting for better edge finish. Not all plasma torches can do this so it would be very interesting to both see if it actually works and well it works. YOU'R THE MAN.

First photo is a closeup of stainless 316 and this is the scrap section

As all can see there is no burnt sugared section on the cut edge. The edge is smooth and shiny.

Even though the alli doesn't look like it, it is very much smoother and almost shiny like on the cut edge. The dross is less and the fume generated during cutting is less.

Now, are there other ways to achieve this, well yes, however this is what I have done to suit me. I wanted primarily to have a better edge when cutting stainless and this is what I have achieved, the alli was a bonus. I tried this a long time ago using a nitrogen bottle, yes it worked but consumed 'very much' nitrogen so I got a nitrogen generator. Problem solved. Also to note that we are cutting stainless at about 80% of the compressed air cut speed. With no oxygen there is no exothermic reaction 'thermal oxidation which is why you get that sugary burnt look' it is purely cut by the thermal temperature of the plasma flame. Alli on the other hand there is no speed change from the book spec. My two cents worth

Good afternoon @Hood. There has been talk and some vids a while ago about submersing (to what extent I don't know) material under the water and cutting for better edge finish. Not all plasma torches can do this so it would be very interesting to both see if it actually works and well it works. YOU'R THE MAN.

When it eventually turned up the next day, 3 hours later than we were told, cranes had gone to another job, so had to rebook onto a later flight while we waited for them to finish and come back.

When it eventually turned up the next day, 3 hours later than we were told, cranes had gone to another job, so had to rebook onto a later flight while we waited for them to finish and come back.