You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Kram

Member

- Messages

- 8,380

- Location

- Sussex

Yes its done quite a bit of cutting and teeth still bloody sharp. Unsure where to buy replacement discs they dont seem common, 1.1mm thick (how it cuts with a tiny battery) 85mm, 15mm bore.

Enjoying this. Old pallet lengths chopped length ways for new duck board - this is my standing area for lathe, 500x400mm Old one is rotten.

Old one is rotten.

Enjoying this. Old pallet lengths chopped length ways for new duck board - this is my standing area for lathe, 500x400mm

Old one is rotten.

Old one is rotten.

Last edited:

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,214

- Location

- Sevenoaks, UK

Yes its done quite a bit of cutting and teeth still bloody sharp. Unsure where to buy replacement discs they dont seem common, 1.1mm thick (how it cuts with a tiny battery) 85mm, 15mm bore.

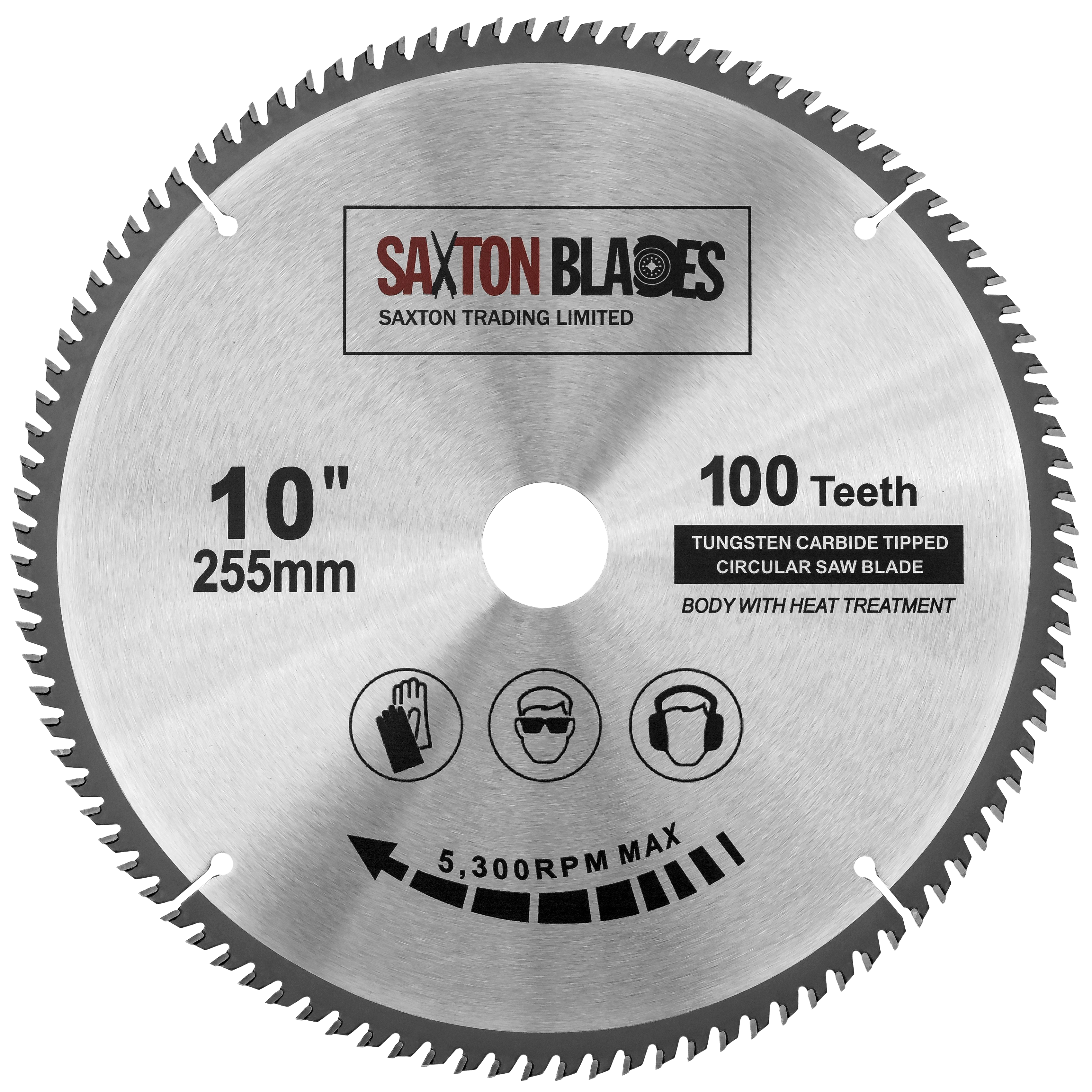

Saxton?

TCT Circular Saw Blades | Saxton Blades

Shop our extensive range of affordable TCT circular blades, designed for precision clean cutting →

The trouble with a lot of these flow switches is they need a fair flow to operate. For example that one in your link needs 6-7lpm and I don't think that much goes to the torch.

It does have a fan but it is not integral to the motor, just a 240v fan fitted to the cooler.

Reduce the bore & the increased flow rate will be metered as greater flow volume.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

The bore is already only about 3mm at the torch.Reduce the bore & the increased flow rate will be metered as greater flow volume.

roblane65

Member

- Messages

- 2,362

- Location

- Newcastle UK

Kram

Member

- Messages

- 8,380

- Location

- Sussex

Looks massively overbuilt for just holding up screens. You could probably hang 32 CRTs on that! I used to have a massive CRT and it weighed about 50kg, bent my desk like a bananna.

Last job today got bandsaw out, put the fine pitch Milwaunkee blade back in and cut some 45 degree lengths, to be the frame for welding bench. The angle is a couple degrees out but apart from that Im happy, should use it more often!

Last job today got bandsaw out, put the fine pitch Milwaunkee blade back in and cut some 45 degree lengths, to be the frame for welding bench. The angle is a couple degrees out but apart from that Im happy, should use it more often!

Last edited:

Did this very same mod to my lathe. I also made a solid post to replace the compound slide. I only put the compound slide on when needed now. Which isn't very often. Both mods were from journeyman's workshop website. I also did the mod to disengage the banjo that carries the change wheels, so they only run when needed, this is a great modification.Not today, but I got this finished last weekend. After chatting with @Pete. this morning, I decided to post up some pics!

It’s a 4 bolt compound slide clamp for the 920 mini lathe. The standard 2 bolt affair is said to rock somewhat, although I can’t say that I’ve ever noticed it on mine. Anyhow, it’s supposed to be a very worthwhile modification, so I thought I’d give it a go.

I screwed up a little at the end, as I didn’t notice that the bandsaw bow was off square slightly, so after it was squared up in the mill, the graduated swivel is a little more exposed that originally expected, but it won’t affect the way if functions at all.

This is the 2 bolt original clamp:

View attachment 280032

And this is the new one:

View attachment 280033View attachment 280034View attachment 280035View attachment 280036

It's made from a bit of plain 15mm mild steel, so I was quite pleased with the finish I got. It was the first time I'd 'properly' used the mill so it was all a bit of trial and error and guesswork with regards to feed speed and tool speed, and I also discovered that a higher spindle speed on the lathe gave a better surface finish, so all in all I learnt quite a bit on this job! Happy days!

Next up I need to make a couple of new T bolts for it, as I'm just using ground down M6 screws at the moment, and I think they need a little more surface area to prevent the heads digging in to the T slots.

Also judging by the photos it looks to be sitting a little ****** on the cross slide, so I'm hoping that it will square up when I get it screwed down properly.

henry Kadzielski

Member

- Messages

- 1,203

- Location

- Australia Wollongong

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,689

- Location

- North Kent, UK

That looks like a very interesting site - I’ll have a good look later on.Did this very same mod to my lathe. I also made a solid post to replace the compound slide. I only put the compound slide on when needed now. Which isn't very often. Both mods were from journeyman's workshop website. I also did the mod to disengage the banjo that carries the change wheels, so they only run when needed, this is a great modification.

Here’s the link if anyone’s interested:

Journeyman's Workshop - home workshop and model engineering

home workshop engineering, model engineering, model boats, wood turning, machine reviews and upgrades, simple projects and plans, metalworking techniques and tips - Journeyman's Workshop -

The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 20,170

- Location

- Going Away.

This vice needed a new/replacement jaw.

I had ordered one, but due to the incompetence of UPC frome depot. I don't have one arriving.

So, I raided the scrap pile.

Found some suitable imperial bar, from an old gate.

Her you see the bar cut to near size and holes drilled and taped.

As my local fixing supplier did not have any 1/4 unc C sunk screws I had to bodge.

The bolts were converted into Grub screws, loctited into place and preened over the make sure they don't come loose.

waddycall

Member

- Messages

- 2,008

- Location

- Cornwall

Just finished a west Greenland style sea kayak paddle for Mrs Waddycall who can get shoulder pain with a euro paddle. Quite pleased with it as it used to be a horrible twisted rough sawn piece of tantalised timber. If the dimensions work out ok for her I’ll make a nice one out of western red cedar.

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

The bolts were converted into Grub screws, loctited into place and preened over the make sure they don't come loose.

Versatility the keyword

MattF

Forum Supporter

- Messages

- 18,426

- Location

- South Yorkshire

Versatility the keyword

Versatilty the new word for bodging then?

The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 20,170

- Location

- Going Away.

No.Versatilty the new word for bodging then?

It replaces:

Being tight.

Why type 2 words, when one will do.