You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Mick Annick

Forum Supporter

- Messages

- 2,992

- Location

- Burgundy, France (450 miles SE of Somerset)

Several times a week,it’s how I charge for most steel.

Makes sense, I order steel by the metre and pay by the kilo!

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

Attacked the hedge today, Quite liking cordless Makita trimmer does the job nicely and battery were ok just charging them over lunch as they went down to 2 bars.

The result of a few hours of trimming and messing around with a stepladder.

Tarp made for easy cleanup just use it to bring it all into middle then scoop into brown bin

brewdexta

The biggest tool in the box

- Messages

- 5,753

- Location

- UK

I've just finished the last of the big drawers for the kitchen. I still have 14 through dovetail drawers to make for the utility larder and 12 small one for the kitchen for odds and sods. These will have half blind dovetails.

I did buy half a dozen sliding wire baskets but came to the conclusion they were carp so replaced them too. I just have to put fronts on the top drawers, and cupboard doors over the bottom ones. The packers to once side of the bottom drawers are there so that the drawer misses the door when sliding out. Its a face frame kitchen so this needs to be taken into account.

Cheers

Andy

I did buy half a dozen sliding wire baskets but came to the conclusion they were carp so replaced them too. I just have to put fronts on the top drawers, and cupboard doors over the bottom ones. The packers to once side of the bottom drawers are there so that the drawer misses the door when sliding out. Its a face frame kitchen so this needs to be taken into account.

Cheers

Andy

The_Yellow_Ardvark

I'm a citizen of Legoland travellin' incommunicado

- Messages

- 20,250

- Location

- Going Away.

Spent some time yesterday and today re doing some H&S rules for MIS.

To that end I had to re-stage what happened, complete with mistakes and failures.

This was very strange setting this up.

Everything is wrong!!!!!!!!!!!!!!!!!!!

Scary as well.

But we had 3 fire extinguishers standing by, hose switched on, anything that could burn was removed, fuel was the barest amount.

The units were pre-warmed outside. So the burn time inside was the shortest we could get away with. We even had Naval Anti-flash on.

The things wrong here.

2 untested(staged) units going at the same time.

No catch tray.

Mocked up fuel leak. It was water.

Inside.

Plus much more.

More messing around, more staging and mocking up. To a point.

Rear unit. Leaking, not enough pressure to vaporise the fuel and the warming depression over filled.

The front unit.

This has been over pressurised, the give away is the liquid fuel on the vice and work top.

That was not allowed to do that for very long.

So we reset again, sorted it all out and did another incorrect test.

This was so wrong, but had to be done to be able re-write the rules, again.

I was pleased to finish this as everything was against the grain.

The 2 torches are mine, so I know they work. But it took some thinking on how to make it look wrong.

To that end I had to re-stage what happened, complete with mistakes and failures.

This was very strange setting this up.

Everything is wrong!!!!!!!!!!!!!!!!!!!

Scary as well.

But we had 3 fire extinguishers standing by, hose switched on, anything that could burn was removed, fuel was the barest amount.

The units were pre-warmed outside. So the burn time inside was the shortest we could get away with. We even had Naval Anti-flash on.

The things wrong here.

2 untested(staged) units going at the same time.

No catch tray.

Mocked up fuel leak. It was water.

Inside.

Plus much more.

More messing around, more staging and mocking up. To a point.

Rear unit. Leaking, not enough pressure to vaporise the fuel and the warming depression over filled.

The front unit.

This has been over pressurised, the give away is the liquid fuel on the vice and work top.

That was not allowed to do that for very long.

So we reset again, sorted it all out and did another incorrect test.

This was so wrong, but had to be done to be able re-write the rules, again.

I was pleased to finish this as everything was against the grain.

The 2 torches are mine, so I know they work. But it took some thinking on how to make it look wrong.

- Messages

- 13,490

- Location

- England

doubleboost

Member

- Messages

- 3,940

- Location

- Newcastle upon Tyne England

mtt.tr

Member

- Messages

- 8,137

- Location

- Essex/Suffolk border

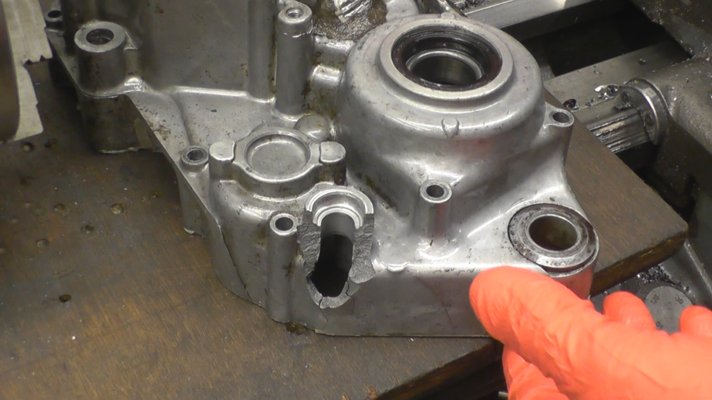

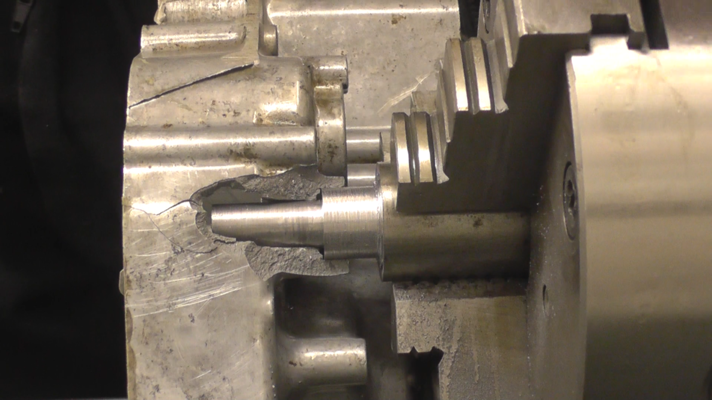

Not made but repaired

Nasty oily aluminiumView attachment 252709 View attachment 252710 View attachment 252711

Well done sir, getting good at this

slim_boy_fat

Member

- Messages

- 29,187

- Location

- Scottish Highlands

this is what i was fitting friday

How will those eventually be secured to the floor?

Anguz

Forum Supporter

- Messages

- 2,003

- Location

- Northamptonshire

re bearinged my old Clark?? band saw... both oilite bearings on the blade wheels replaced from bearingboys

the guide bearings replaced with the finest chinesium..

see how long they last... in total it cost me 20 quid, its gone from unusable to as rubbish as the day i aquired it

just got to sort the switch now

the guide bearings replaced with the finest chinesium..

see how long they last... in total it cost me 20 quid, its gone from unusable to as rubbish as the day i aquired it

just got to sort the switch now

Feet 'n Inches

Out of the rat-race at last

- Messages

- 533

- Location

- Devon, GB

Today it was two holes in my workshop door.

My bandsaw is positioned just inside the door and the lights tend to cast a shadow making it tricky to measure on occasions. Fine during the summer, the door stays open and the sunlight floods in but in the winter, it's a different story. The 'glass' is 10mm thick perspex which has an opaque sheet bonded to it on one side - it will come off but it sticks pretty well. I welded 10mm round bar across the perspex as a bit of additional security should some smart alec come a-knocking. Next fine day I'll give the door a coat of paint.

The little plaque on the right, partially in shot says "Grumpy's Shed". No prizes for guessing who bought me that.

My bandsaw is positioned just inside the door and the lights tend to cast a shadow making it tricky to measure on occasions. Fine during the summer, the door stays open and the sunlight floods in but in the winter, it's a different story. The 'glass' is 10mm thick perspex which has an opaque sheet bonded to it on one side - it will come off but it sticks pretty well. I welded 10mm round bar across the perspex as a bit of additional security should some smart alec come a-knocking. Next fine day I'll give the door a coat of paint.

The little plaque on the right, partially in shot says "Grumpy's Shed". No prizes for guessing who bought me that.

The_Yellow_Ardvark

I'm a citizen of Legoland travellin' incommunicado

- Messages

- 20,250

- Location

- Going Away.

Got a few items over the weekend.

English oak and in need of a lot of TLC.

0V to 450V over 3 terminals. Plus one Common.

Over the years the box has been varnished, lacquer and French polish. Leading to a real mess. Plus it had caused the frame to twist. The sealing of the outside and the heat and damp inside added to the issue.

Here you can see the depression I the mid section of the side, taking a plane to it would of not been a wise move. So using a scraper plane, cabinet scrapers and wire wool. plus lots of "Meths." we had it back to bare wood.

The MCM was held on the 0 Volt position. Of course releasing the stress showed the coil frame was warped. Adjusting the frame screws I could get the needle to move to any position. But connecting it to a suitable power supply it was not a stable or a steady readout.

The hunt is on to find a replacement or finding a way to repair it.

Bit of history on the back of the scale.

This and construction marks were saved. Made it a bit difficult to save the ones on the wood. But it was done.

The metal work was painted in Satin black, visible screws were polished and the inside was waxed.

The bottom bit of wood, had a name on it and the words:

"writing to meter."

It would only fit one way.

10 coats of French polish.

The grain shows up very well.

All the screws were an odd size. All the old holes were filled with sawdust and glue. Re-drilled and the slots all point the same way.

The Leather handle is still drinking leather food. But it is intact and it will recover.

All done.

English oak and in need of a lot of TLC.

0V to 450V over 3 terminals. Plus one Common.

Over the years the box has been varnished, lacquer and French polish. Leading to a real mess. Plus it had caused the frame to twist. The sealing of the outside and the heat and damp inside added to the issue.

Here you can see the depression I the mid section of the side, taking a plane to it would of not been a wise move. So using a scraper plane, cabinet scrapers and wire wool. plus lots of "Meths." we had it back to bare wood.

The MCM was held on the 0 Volt position. Of course releasing the stress showed the coil frame was warped. Adjusting the frame screws I could get the needle to move to any position. But connecting it to a suitable power supply it was not a stable or a steady readout.

The hunt is on to find a replacement or finding a way to repair it.

Bit of history on the back of the scale.

This and construction marks were saved. Made it a bit difficult to save the ones on the wood. But it was done.

The metal work was painted in Satin black, visible screws were polished and the inside was waxed.

The bottom bit of wood, had a name on it and the words:

"writing to meter."

It would only fit one way.

10 coats of French polish.

The grain shows up very well.

All the screws were an odd size. All the old holes were filled with sawdust and glue. Re-drilled and the slots all point the same way.

The Leather handle is still drinking leather food. But it is intact and it will recover.

All done.

Kram

Member

- Messages

- 8,460

- Location

- Sussex

Getting further with lathe guard. Ive not tried to "fit" parts like this before, could use any tips how to get the last bends correct. Problem is the big curved bit is free to move. I dont want to tack it in place, just incase the vfd doesnt like it.

The small window surrounds a steel column,the exterior doors and windows are from 60/60/4 box,with a cover trim of 80/6 flat ,the finish was natural then varnish,all very heavy,door being 130kg,the wall is 4’ thick necessitated 3 heavy frames in the opening.

Olderisbetter

Member

- Messages

- 3,982

- Location

- Wolverhampton

Sorted out the guttering, soffit and fascia at my sisters as the cast iron stuff had started to leave the building.