aye was wondering that, if you could have machined a ring to take a steel plate, that was consumable, but I suppose by the time you've done that, then faffed about getting teh worn and old bolts out etc, you be quicker skimming as you say....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

roblane65

Forum Supporter

- Messages

- 2,407

- Location

- Newcastle UK

Dog wash perhaps ?What’s the low sink / bath (?) for?

Ubique

Member

- Messages

- 2,436

- Location

- East Midlands

It's so the seven Dwarfs can do the washing-up for Snow WhiteDog wash perhaps ?

eLuSiVeMiTe

Member

- Messages

- 16,282

- Location

- ......

As Rob said. Dog showerWhat’s the low sink / bath (?) for?

eLuSiVeMiTe

Member

- Messages

- 16,282

- Location

- ......

Final push tomorrow.Me and mate did a bit of a garage conversion type job with a big tray and thermo mixer just for washing the 5 or dogs they had , thats a bit posher though

When you gonna get that door on !

Skirting in both rooms. Seal the shower (grouted earlier gotta love rapid set) freezer door on. And make some changes to the poor design to make this section look finished rather than a bodge. Swap 600 for 500 door add frame and infill.

eLuSiVeMiTe

Member

- Messages

- 16,282

- Location

- ......

eLuSiVeMiTe

Member

- Messages

- 16,282

- Location

- ......

The 500 door idea is mine tbh. Easier to stick a 1000 corner base divide in the 600 and hang a new door than it is to modify around the soil pipe and fit a new unit.I do love it when kitchen planner go theres a couple of end panels and a door to make that .

roblane65

Forum Supporter

- Messages

- 2,407

- Location

- Newcastle UK

I've had the same a few times with end panels , usually when the front edge has a slightly different profile and you can't rip a piece of the front and back of panel to make something up , Normally there not very happy when you point this out and want more panels .

eLuSiVeMiTe

Member

- Messages

- 16,282

- Location

- ......

Wrens painted range are only pained both sides on one edge. Pita as standard practice for me to split a panel in half when used mid run.I've had the same a few times with end panels , usually when the front edge has a slightly different profile and you can't rip a piece of the front and back of panel to make something up , Normally there not very happy when you point this out and want more panels .

Always good to be economic with panels for the unexpected issues.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

When I was starting out as a SE alarm installer for a company training me up ( 1982 I was fitting hidden sunken magnetic contacts to the top of a door & frame .Dog wash perhaps ?

I looked down to my left behind the door , there was a lovely white enameled bath in the room to the rear of the door .

I laid a thick covering of folded dust sheets in the bath & over the baths edge .

Got busy everything done , wires connected ....coming down the stepladder , the pin hammer in my tool belt hoop on my right caught the top handle of the steps and it flipped out the wire loop on the belt on to my left foot head down , to then pinwheel & land shaft down in the bath with a dull clang then gracefully slide down the back of the bath on to the dust sheet . The owner came screaming in when he heard the dull clang ..before he'd even got to the dog washroom he was shouting " You've put a chip in my brand new bath that'll cost you £400 for a new one . My boss was called ..looking daggers at me & said it would be an insurance claim against the company .

I was puzzled .......it was only a couple of hours after we'd left the place I realised that the chip was a good 9 inches down on the bottom of the bath , I'd wiped the bath out to remove any dust or chips of wood from my 3 inch long hand auger

Realised there were no enamel fragment chips in the bottom of the bath or on the newish yellow duster cloth I was using. Pointless telling my boss , as far as he was concerned it was going to cost him on his insurance premiums & I doubt he would have backed me in front of the customer .

It gave me great pleasure to go to a pub party nearby almost 15 months later to find he'd been put away for embezzlement . Who needs money to pay their debts?

selectedgrub

Member

- Messages

- 3,549

- Location

- New Zealand

eLuSiVeMiTe

Member

- Messages

- 16,282

- Location

- ......

Final push tomorrow.

Skirting in both rooms. Seal the shower (grouted earlier gotta love rapid set) freezer door on. And make some changes to the poor design to make this section look finished rather than a bodge. Swap 600 for 500 door add frame and infill.

View attachment 314352

Before pic in the quote.

Lot of bloody work I'm not being paid for

Feet 'n Inches

Out of the rat-race at last

- Messages

- 533

- Location

- Devon, GB

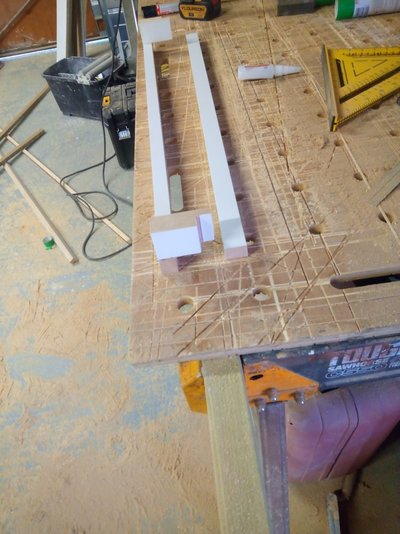

I came into my local men's shed the other day to see two of the guys drilling into the end of a 3" cylinder of wood about 9" in length with a fairly big Forstner bit. One was operating the pillar drill, the other holding on tightly to keep the cylinder level (kids, don't try this at home!). OK, so it worked, but the risks were pretty high to say the least. I decided to knock up a vice that could hold a piece of round, square or rectangular timber so that the ends could be drilled. Now we don't have any milling or turning equipment or other more sophisticated machinery for that matter, so everything I make tends to be done mainly by hand. The vice is a mix of offcuts and reclaimed steel including Dexion racking angle for the slide guides. It may look crude but it does do the job.

eLuSiVeMiTe

Member

- Messages

- 16,282

- Location

- ......

Situations like that I usually knock up a clamp. Bit of 2x stock with a half round of the correct diameter jigsawed out then clamp it down each side of the 2x stock.I came into my local men's shed the other day to see two of the guys drilling into the end of a 3" cylinder of wood about 9" in length with a fairly big Forstner bit. One was operating the pillar drill, the other holding on tightly to keep the cylinder level (kids, don't try this at home!). OK, so it worked, but the risks were pretty high to say the least. I decided to knock up a vice that could hold a piece of round, square or rectangular timber so that the ends could be drilled. Now we don't have any milling or turning equipment or other more sophisticated machinery for that matter, so everything I make tends to be done mainly by hand. The vice is a mix of offcuts and reclaimed steel including Dexion racking angle for the slide guides. It may look crude but it does do the job.

View attachment 314448

jordhandson

Member

- Messages

- 1,430

- Location

- Dorset

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

That's nice & handy if the guys have the presence of mind & intelligence to use it .I came into my local men's shed the other day to see two of the guys drilling into the end of a 3" cylinder of wood about 9" in length with a fairly big Forstner bit. One was operating the pillar drill, the other holding on tightly to keep the cylinder level (kids, don't try this at home!). OK, so it worked, but the risks were pretty high to say the least. I decided to knock up a vice that could hold a piece of round, square or rectangular timber so that the ends could be drilled. Now we don't have any milling or turning equipment or other more sophisticated machinery for that matter, so everything I make tends to be done mainly by hand. The vice is a mix of offcuts and reclaimed steel including Dexion racking angle for the slide guides. It may look crude but it does do the job.

View attachment 314448

If you can't knock something up like that get the help of someone to hold it parallel to the ground in a vice and drill from one end using the Mk 1 eyeball to keep it on the lateral axis and your mate doing the other sighting line to keep telling you up a tad down a tad to follow the line of the wood .

For short pieces I often use a right angle of wood glued & screwed up out of 44 mm planed wood .. Turn it on the edge side , set it on a 15 mm square of ply to stop cutting right through and push the round or square wood into the crook of the right angle then drill down with the press .

, till father said they do them in screwed fix for 12 squid each.

, till father said they do them in screwed fix for 12 squid each.