Prajna

Fixing things for the love of it

- Messages

- 683

- Location

- Castelo Branco, Portugal

Hey, another kiwi. Gidday.^^ Nice simple practical design.

Good work thanks for sharing.

Hey, another kiwi. Gidday.^^ Nice simple practical design.

Good work thanks for sharing.

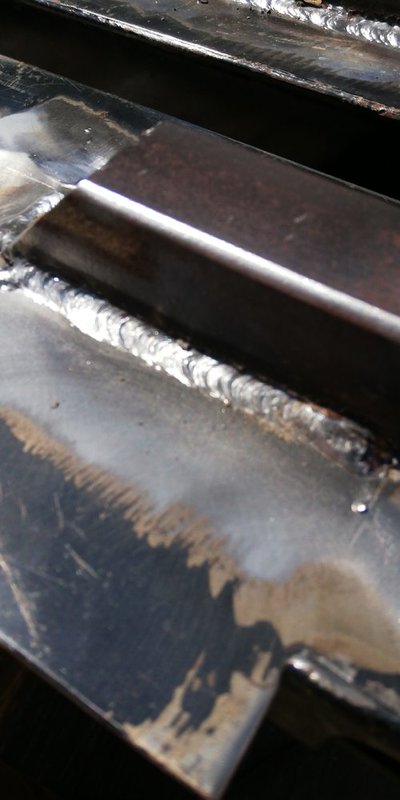

They won't fall off that's for sure.After maybe a month or two I've welded something.

Truck sides column , just added two Square tube receivers for a stiffening bar ,to avoid them to spread open .

I'll weld them on the truck bed most likely next Friday .

Considering that it's been awhile since I've welded something , that it's a fillet joint on 2mm box tube and 10mm plate , that I've used 2.5mm(3/32") 7018 for that .

I think that's not too bad I believe.

It will be way easier to weld them in place ,10 on 5mm vertical up

View attachment 282327 View attachment 282328 View attachment 282329 View attachment 282330 View attachment 282331

Lumpy red poo.

View attachment 282413

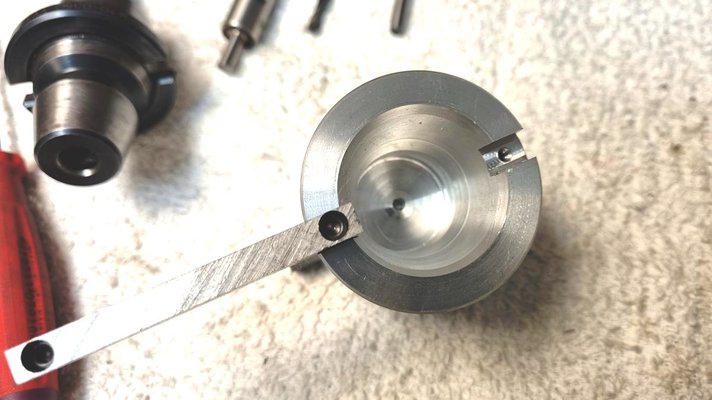

Is that for presetting the tool heights or just for tightening?Well, it's different. Need to see it all back together, will prolly look good.

Myself, I made a toolholder for the new quickchange system, fast n dirty. It too came out okay, I was using the system itself to do the drilling and machining and it is one of the best things I have bought. Need more toolholders but they are going to have to wait a while just now. I have milled a 10mm recess in the base and bolted a bit of keysteel in there so when I am using it I just grip it in the vice and off I go.

View attachment 282414View attachment 282415View attachment 282416View attachment 282417View attachment 282418

Is that for presetting the tool heights or just for tightening?

Bearings arrived so I was able to assemble my hold-down clamps; F-clamps, stainless M12 bolts and locknuts from Zoro and 63001-2RS (28mm OD, 12mm ID, 12m thick) bearings from eBay - made six in total. In all they came to £10.40ea and they work a treat so I'm feeling a bit chuffed.

Do you have a pic of these in action? Do you think they would work in 10 or 12mm plate?

There are basically 2 ways to do toolsetting on the CNC, one is online the other offline. I prefer the offline and made up a setter that integrates with Mach for the Beaver and then when I got the Chiron I made another for it, they work greatJust for tightening. I have a similar but completely different system for the CNC (?). The toolholder in the CNC is not working as it should and it is a palaver getting the holder itself out so I have all of the tooling for that Mill in ER11 toolholders and with a quick twist of an Allen key they are interchangeable. I will get it fixed, eventually.

I do want to make some sort of toolsetter but I need to crack on with actual work at the minute. I am able to research it at the minute though.

I'll take some photos of them being used in the morning and send them to you.

Nice buggy, is it a kit or did you fabricate yourself? Would you mind showing the drivetrain?