- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

South Bend Heavy 10

- Thread starter Pete.

- Start date

it has what's called a 'war finish' which means that the machine was made to the same standard as any other except they didn't waste time on the cosmetic details.

It is going to make a very nice lathe.

With respect to War finish. The capstan lathe I was put on as an apprentice in the 1970s, had a plate on the headstock, entreating me to produce components to "war finish"

Pete.

Forum Supporter

- Messages

- 15,072

- Location

- Kent, UK

What paint did you use Pete? It looks really good in your photos.

It's Dark grey enamel from eBay seller arcriteweldingsafetyltd. I have painted with a roller and laid it off with a long bristle brush (thanks for the tip @Windy Miller). Haven't tried spraying it yet but I am hoping to do so on the headstock components. I've never had much luck at spray painting.

Pete.

Forum Supporter

- Messages

- 15,072

- Location

- Kent, UK

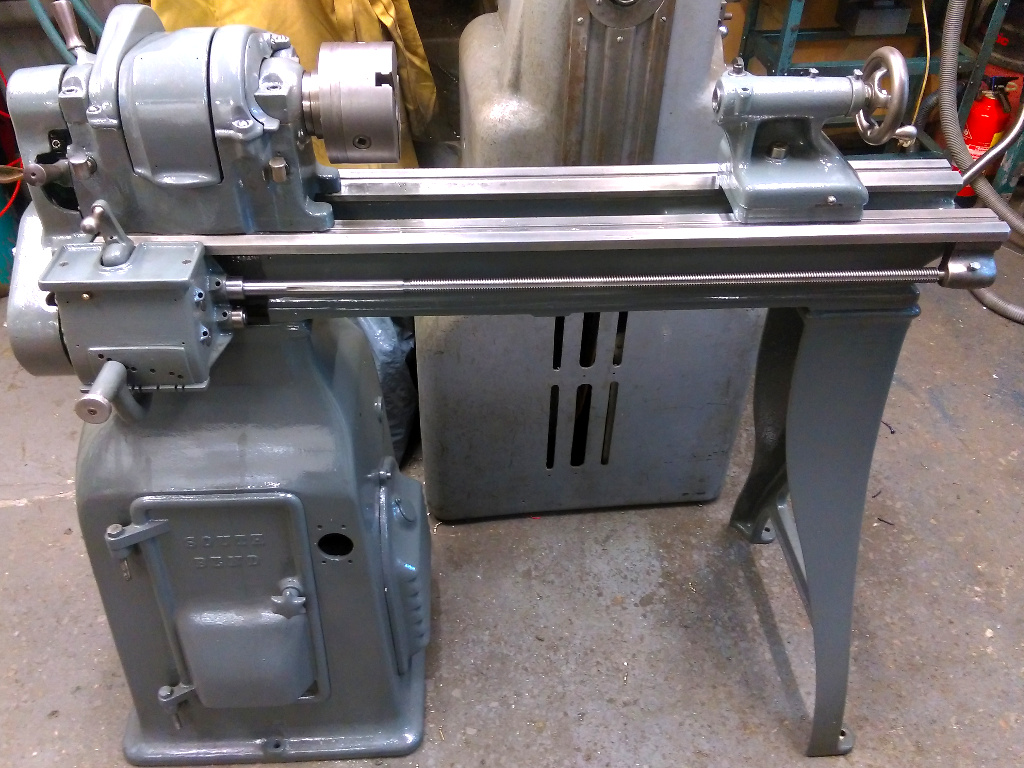

Well, quite a few weeks have gone by and my workload has made it hard to get any solid time on the lathe but I've sneaked a few hours in here and there. The bed is painted and built on to the stands. Headstock painted too and rebuilt then fitted to the bed. The gearbox is also painted and rebuilt but I think I'm going to have another go at painting that because I'm disappointed with how the paint came out.

All of the lubrication system is stripped and flushed, felts flushed out with copious amounts of brake cleaner. Gotta strip all the crappy blue paint off the spring cap oilers and then they will be re-fitted too.

So here she stands right now. Bit of a contrast from when I bought it:

On the whole I'm very pleased with how it's coming out. The mechanical parts are in truly superb condition. The spindle, gearbox, end cluster is all perfect and even the leadscrew has no discernable wear. The only thing I had to do was re-make the shaft for the sliding gear on the end cluster because for some reason it had been run with the locating ball not in the groove so had work two extra grooved in the shaft. I didn't get a photo of the shaft but here's a little video of it being machined on my wonderful 10EE which as ever is a complete joy to use:

https://www.dropbox.com/s/d85vq6jp7meu2u9/heavy10 spindle made on 10ee.mp4?dl=0

What is a bit of a let-down is the South Bend's bed which has suffered clumsy handling and picked up a collection of dings. I've decided to leave that alone - I could spend £4-500 sending it away from grinding but it wouldn't increase the value by close to that much and the marks don't hinder the operation so it doesn't make sense.

All of the lubrication system is stripped and flushed, felts flushed out with copious amounts of brake cleaner. Gotta strip all the crappy blue paint off the spring cap oilers and then they will be re-fitted too.

So here she stands right now. Bit of a contrast from when I bought it:

On the whole I'm very pleased with how it's coming out. The mechanical parts are in truly superb condition. The spindle, gearbox, end cluster is all perfect and even the leadscrew has no discernable wear. The only thing I had to do was re-make the shaft for the sliding gear on the end cluster because for some reason it had been run with the locating ball not in the groove so had work two extra grooved in the shaft. I didn't get a photo of the shaft but here's a little video of it being machined on my wonderful 10EE which as ever is a complete joy to use:

https://www.dropbox.com/s/d85vq6jp7meu2u9/heavy10 spindle made on 10ee.mp4?dl=0

What is a bit of a let-down is the South Bend's bed which has suffered clumsy handling and picked up a collection of dings. I've decided to leave that alone - I could spend £4-500 sending it away from grinding but it wouldn't increase the value by close to that much and the marks don't hinder the operation so it doesn't make sense.

Pete.

Forum Supporter

- Messages

- 15,072

- Location

- Kent, UK

Cheers Matt!

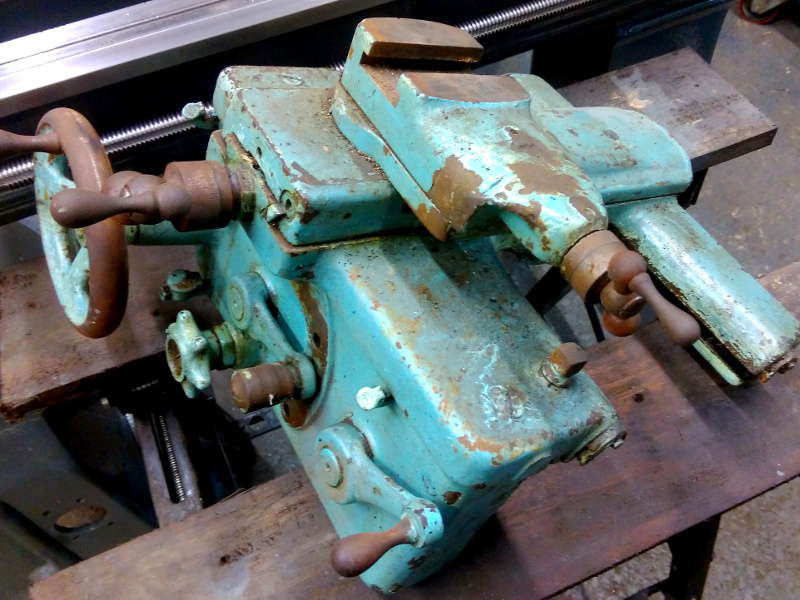

So what's left to do is all the drivetrain in the cabinet, electrics, try to find (or make) a belt tensioning handle, and the biggest job - this!

The whole lot is getting stripped, serviced and scraped then rebuilt with new wipers. Despite the rough appearance it's all actually in great condition. Apart from the scraping I might convert the dials to the bigger type, and perhaps make them diameter-reading instead of radius. I'll have to see about that.

So what's left to do is all the drivetrain in the cabinet, electrics, try to find (or make) a belt tensioning handle, and the biggest job - this!

The whole lot is getting stripped, serviced and scraped then rebuilt with new wipers. Despite the rough appearance it's all actually in great condition. Apart from the scraping I might convert the dials to the bigger type, and perhaps make them diameter-reading instead of radius. I'll have to see about that.

slim_boy_fat

Member

- Messages

- 29,186

- Location

- Scottish Highlands

It is going to make a very nice lathe.

With respect to War finish. The capstan lathe I was put on as an apprentice in the 1970s, had a plate on the headstock, entreating me to produce components to "war finish"

My Dad was a capstan setter with the CPT [as it then was, just Consolidated Pneumatic] factory in Fraserburgh so he might have played a small part in some of the 'war finish' stuff from that time.

grim_d

Unlikeable idiot.

- Messages

- 4,160

- Location

- Scotland - Ayrshire

My Dad was a capstan setter with the CPT [as it then was, just Consolidated Pneumatic] factory in Fraserburgh so he might have played a small part in some of the 'war finish' stuff from that time.

I have a couple of very old consolidated pneumatic rivet guns at work.

For their age they still work spectacularly well much more control than their modern Chicago pneumatic counterparts. They have their scars but I've done nothing more than clean them.

Perhaps your dad played his part in making them too.

You are doing a great job! Lovely to see that "piece of junk" coming back to life.

A few years ago i bought 2 lathes - a MK1 Colchester Triumph and a Triumph 2000. Always wanted the 2000 - my dream lathe. Got it very cheap as well as the bloke had to leave his place in a hurry.

Anyway it turned out the older lathe was in far better condition under the surface whilst the 2000 was pretty worn.

Sadly i ended up having to sell the 2000 for what i paid for it as i didnt have room for 2 big lathes. Seeing this restoration made me realise i did the right thing after all.

A few years ago i bought 2 lathes - a MK1 Colchester Triumph and a Triumph 2000. Always wanted the 2000 - my dream lathe. Got it very cheap as well as the bloke had to leave his place in a hurry.

Anyway it turned out the older lathe was in far better condition under the surface whilst the 2000 was pretty worn.

Sadly i ended up having to sell the 2000 for what i paid for it as i didnt have room for 2 big lathes. Seeing this restoration made me realise i did the right thing after all.

God mode restorations

Member

- Messages

- 8,100

- Location

- uk colchester

That's the same as what I have to do on mine. Strip. Clean. Scrape .Cheers Matt!

So what's left to do is all the drivetrain in the cabinet, electrics, try to find (or make) a belt tensioning handle, and the biggest job - this!

View attachment 154869

The whole lot is getting stripped, serviced and scraped then rebuilt with new wipers. Despite the rough appearance it's all actually in great condition. Apart from the scraping I might convert the dials to the bigger type, and perhaps make them diameter-reading instead of radius. I'll have to see about that.

Pete.

Forum Supporter

- Messages

- 15,072

- Location

- Kent, UK

I had a load of DIY and maintenance chores to do so I was late getting going on this. At 3.40 pm it looked like this:

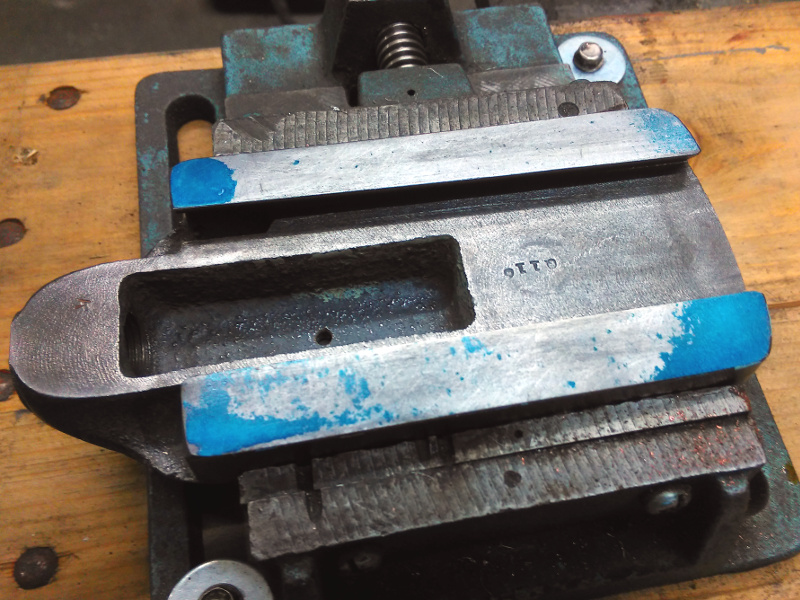

I stripped and cleaned it down. There's faint evidence of original (or rebuild) scraping on the cross-slide ways which is always encouraging because the cross-slide is where you usually get the worst wear.

Saddle ways are nice and shiny, though they will be getting scraped too.

And two hours after starting we have this. The saddle and slides are stripped to bare metal and ready for scraping.

I'm leaving the apron alone until the scraping's done. All it requires is a good clean and paint. I doubt it's ever been apart since the original wicks are still in place. Look at those gears they are perfect.

I stripped and cleaned it down. There's faint evidence of original (or rebuild) scraping on the cross-slide ways which is always encouraging because the cross-slide is where you usually get the worst wear.

Saddle ways are nice and shiny, though they will be getting scraped too.

And two hours after starting we have this. The saddle and slides are stripped to bare metal and ready for scraping.

I'm leaving the apron alone until the scraping's done. All it requires is a good clean and paint. I doubt it's ever been apart since the original wicks are still in place. Look at those gears they are perfect.

Pete.

Forum Supporter

- Messages

- 15,072

- Location

- Kent, UK

Time to appraise the wear on the ways. One of the easiest methods to check if there's significant wear is this method shown here. It doesn't give you a full picture as you don't know if it's the flat ways or the dovetail that's worn (usually it's the flat mostly) but it can give you a good idea. I was really pleased to see that the wear is almost negligible.

You can see that the front 2/3 is worn slightly and the back 1/3 is ever so slightly wider across the vees (about a thou). This is caused by the cross-slide moving over the same section but rarely reaching the end of the ways. Later type machines had much longer cross-slides which were not only more rigid but wore more slowly and more evenly across the whole way.

Here's the compound, also excellent.

Now one problem you very often see with this type of compound mount is shown here. When they manufacture the cross-slide they machine it flat, and machine the underside of the compound swivel flat, and they fit together nicely at first but as soon as they start to wear in the underside of the compound fouls the top of the cross-slide on the non-bearing part when you swing the compound round and this . This one was no exception and it might never be a problem for the user except that I want to scrape this part and I couldn't get the centre 'donut' flat on the plate because of edge burrs and the small wear. I don't want to scrape the whole surface down and they look pretty good if you skim a few thou off so that's what I've done today.

A bit of an unorthodox setup but I didn't want to fiddle around with the face plate and it's only a tiny skim.

And here's how it looks. The compound now nicely clears the cross-slide. Now I can scrape-in the donut ring which is slightly raised, then blue up that scraped part to print the upper part for scraping. It'll be a very nice fit then.

Next job scrape the underside of the compound. As you can see it's got a slight bow in it so it only contacts on the corners, and mostly only on three. This would cause a definite rock under load.

A bit of scraping and we have a nice even spread of points. It'll need some more work tomorrow as I need to use this part to print the compound flat ways, but I've had enough for today.

You can see that the front 2/3 is worn slightly and the back 1/3 is ever so slightly wider across the vees (about a thou). This is caused by the cross-slide moving over the same section but rarely reaching the end of the ways. Later type machines had much longer cross-slides which were not only more rigid but wore more slowly and more evenly across the whole way.

Here's the compound, also excellent.

Now one problem you very often see with this type of compound mount is shown here. When they manufacture the cross-slide they machine it flat, and machine the underside of the compound swivel flat, and they fit together nicely at first but as soon as they start to wear in the underside of the compound fouls the top of the cross-slide on the non-bearing part when you swing the compound round and this . This one was no exception and it might never be a problem for the user except that I want to scrape this part and I couldn't get the centre 'donut' flat on the plate because of edge burrs and the small wear. I don't want to scrape the whole surface down and they look pretty good if you skim a few thou off so that's what I've done today.

A bit of an unorthodox setup but I didn't want to fiddle around with the face plate and it's only a tiny skim.

And here's how it looks. The compound now nicely clears the cross-slide. Now I can scrape-in the donut ring which is slightly raised, then blue up that scraped part to print the upper part for scraping. It'll be a very nice fit then.

Next job scrape the underside of the compound. As you can see it's got a slight bow in it so it only contacts on the corners, and mostly only on three. This would cause a definite rock under load.

A bit of scraping and we have a nice even spread of points. It'll need some more work tomorrow as I need to use this part to print the compound flat ways, but I've had enough for today.

Last edited:

Pete.

Forum Supporter

- Messages

- 15,072

- Location

- Kent, UK

Nice to see that it's not overly worn

It's not worn hardly at all, amazing for a 75 yr old machine, bit of a scraper's dream. I truly think it's done little or no work it's whole life - perhaps it's spent a long time on storage? Normally you get wear on the leadscrew in one area, and the gearbox teeth grind away because it's not a wet sump but this one has no wear in any of them.

Carl Wilson

Member

- Messages

- 2,016

- Location

- Moray

Thank you for posting that. Very interesting and informative.

Carl Wilson

Member

- Messages

- 2,016

- Location

- Moray

Likewise. It's a source of endless fascination for me.

Pete.

Forum Supporter

- Messages

- 15,072

- Location

- Kent, UK

It'll be a source of endless consternation if you ever try it

The blue in I am using is Canode blue. It is applied quite thick in the pics. I like the Stuarts blue but the canode is water-based so cleans up nicely whereas the Stuarts is oil-based and a bit more messy. For fine work you can't beat the Stuarts it shows up better when applied thin.

The blue in I am using is Canode blue. It is applied quite thick in the pics. I like the Stuarts blue but the canode is water-based so cleans up nicely whereas the Stuarts is oil-based and a bit more messy. For fine work you can't beat the Stuarts it shows up better when applied thin.