Pete.

Member

- Messages

- 14,147

- Location

- Kent, UK

In a fit of madness I bought this scruffy-looking lathe which is undergoing a refurb and re-scrape. It's going to take (already taken) a huge number of hours to bring it up to scratch but I reckon it's worth it, especially given it's early history.

So here it is, as found. It's a poor pic but there's no escaping the general neglected condition (outwardly, anyway). I arrange to pop round and collect it, the guy has it half-stripped when I get there so we finish the job and load it in my van.

When I got it home I went looking for the year of manufacture and luckily the South Bend lathe has a healthy following (most popular lathe in America), so it was easy to date it to 1943. Then there was this curious stamp on the bed with initials stamped next to it. Turned out to be the 'flaming bomb' motif of the US Army Ordnance Corps. So this machine was bought new by the US Army in the middle of WW2 and put to use making parts for armaments - it's gotta be worth saving!

And there was this stamped plate on the bed. Basically it has what's called a 'war finish' which means that the machine was made to the same standard as any other except they didn't waste time on the cosmetic details. The castings have been given a rough grind-over to remove the lumps and flashings then it was machined and painted and pressed into use. There must have been enormous pressure on production in 1943.

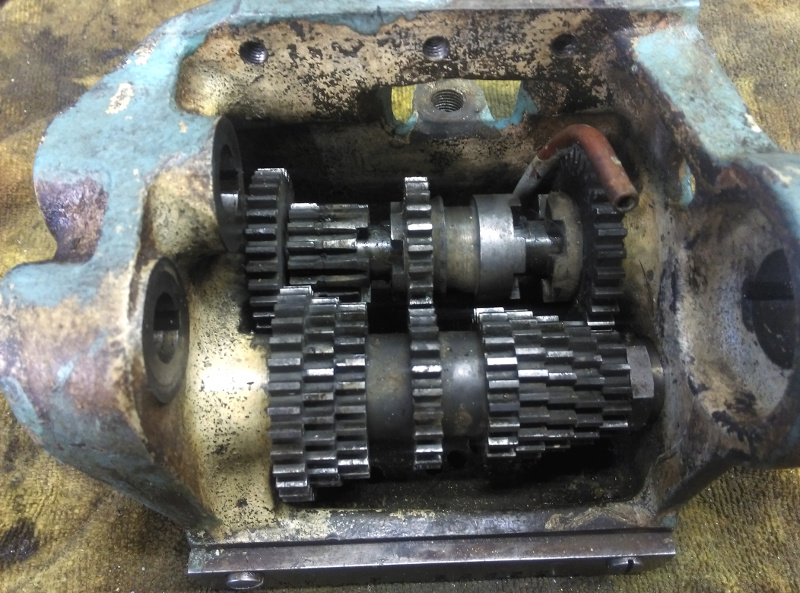

This was a couple of weeks ago and now things have moved on a bit. First thing to do was check out the mechanical condition and I was very surprised to find almost no wear in the bed (though a few dings), little to no wear in the big lead screw and a very gungy but otherwise perfect condition gearbox. It even has the tiny brass plug that caps the oiler hole for the tumbler which is very rare to find!

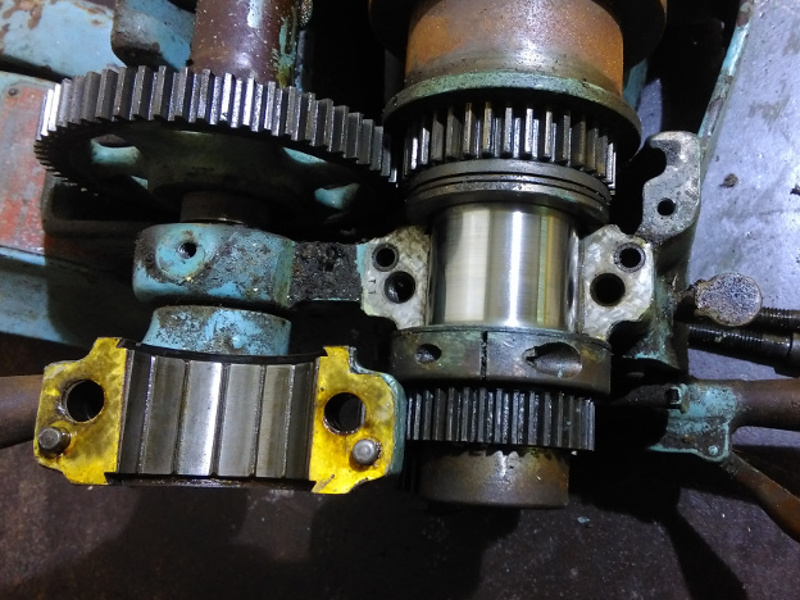

Equally grungy is the headstock:

However, under all that grime and surface rust is a little gem hidden. The spindle and bearings are perfect despite being 75 years old.

And here is why - South Bend's incredibly simple yet effecting spindle oiler. A spring loaded pressed wool felt wicks oil from a small reservoir up to the spindle. The excess oil runs through the grooves to the vee and down the drain hole back into the reservoir. A wick-fed perpetual lubrication system. Beautifully scraped and fitted up luckily it has thankfully never been allowed to run dry.

So here it is, as found. It's a poor pic but there's no escaping the general neglected condition (outwardly, anyway). I arrange to pop round and collect it, the guy has it half-stripped when I get there so we finish the job and load it in my van.

When I got it home I went looking for the year of manufacture and luckily the South Bend lathe has a healthy following (most popular lathe in America), so it was easy to date it to 1943. Then there was this curious stamp on the bed with initials stamped next to it. Turned out to be the 'flaming bomb' motif of the US Army Ordnance Corps. So this machine was bought new by the US Army in the middle of WW2 and put to use making parts for armaments - it's gotta be worth saving!

And there was this stamped plate on the bed. Basically it has what's called a 'war finish' which means that the machine was made to the same standard as any other except they didn't waste time on the cosmetic details. The castings have been given a rough grind-over to remove the lumps and flashings then it was machined and painted and pressed into use. There must have been enormous pressure on production in 1943.

This was a couple of weeks ago and now things have moved on a bit. First thing to do was check out the mechanical condition and I was very surprised to find almost no wear in the bed (though a few dings), little to no wear in the big lead screw and a very gungy but otherwise perfect condition gearbox. It even has the tiny brass plug that caps the oiler hole for the tumbler which is very rare to find!

Equally grungy is the headstock:

However, under all that grime and surface rust is a little gem hidden. The spindle and bearings are perfect despite being 75 years old.

And here is why - South Bend's incredibly simple yet effecting spindle oiler. A spring loaded pressed wool felt wicks oil from a small reservoir up to the spindle. The excess oil runs through the grooves to the vee and down the drain hole back into the reservoir. A wick-fed perpetual lubrication system. Beautifully scraped and fitted up luckily it has thankfully never been allowed to run dry.