eLuSiVeMiTe

Member

- Messages

- 16,441

- Location

- ......

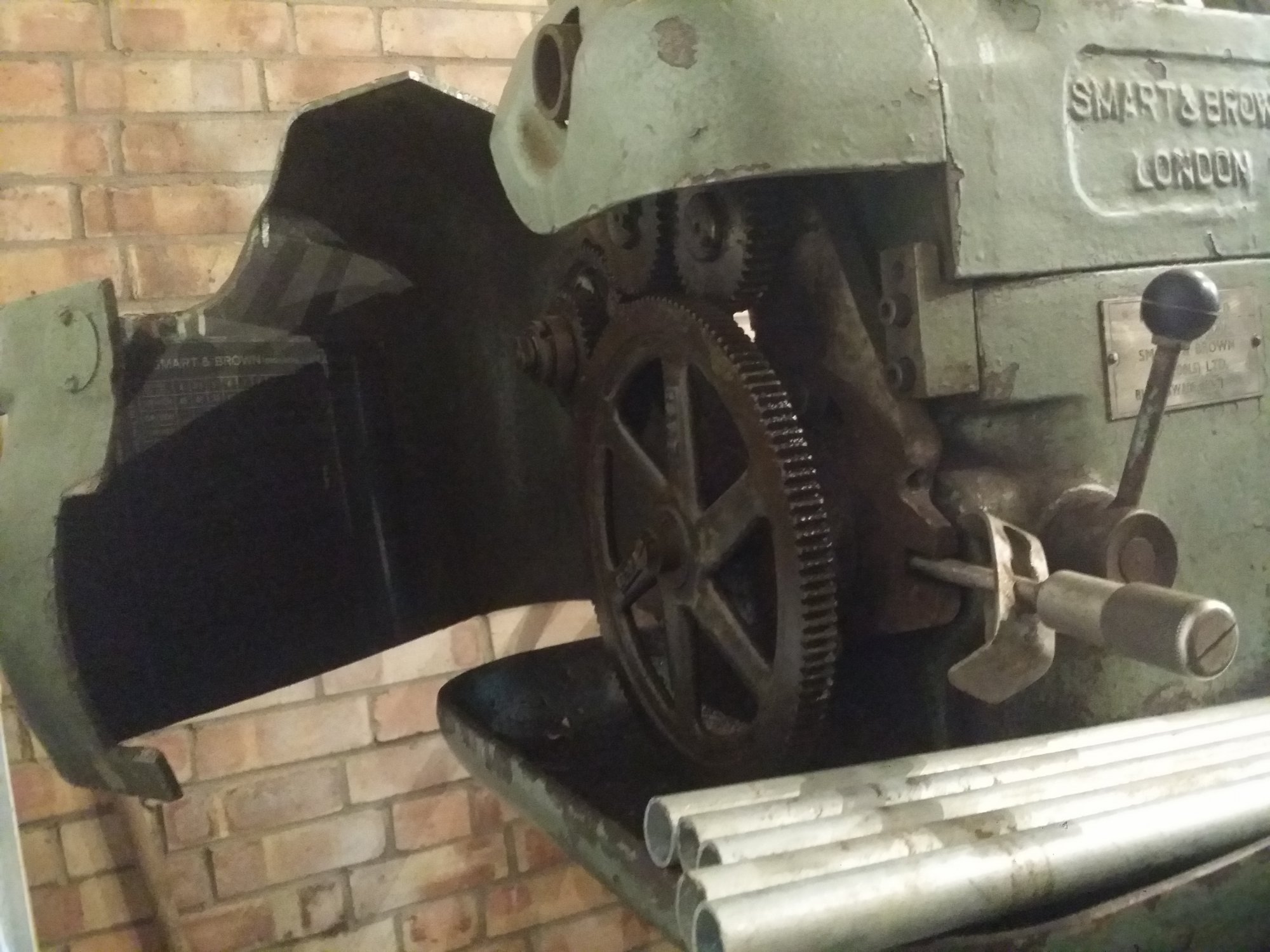

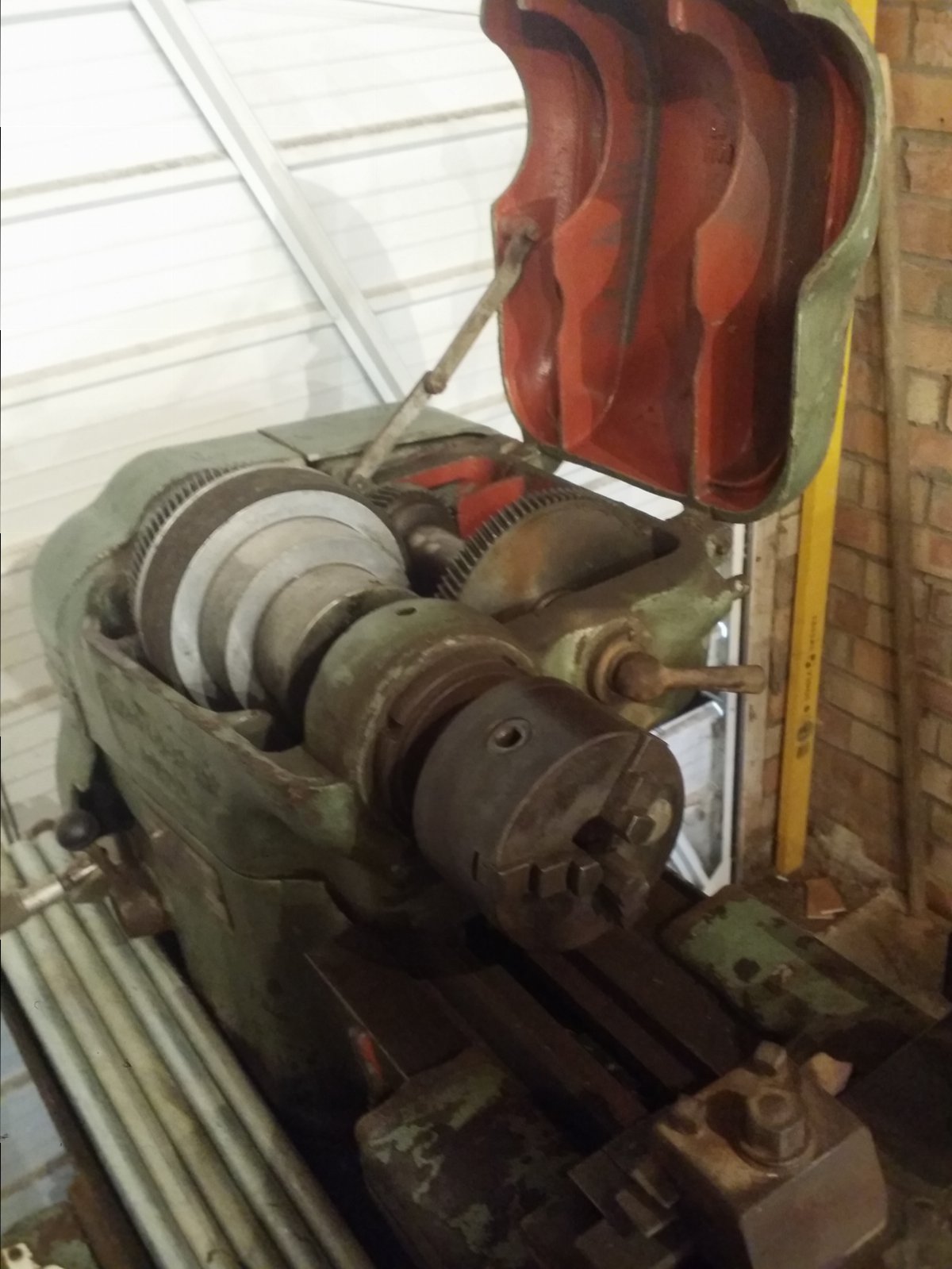

Too many projects on the go and acquired another one this morning. Went in the van on a forklift. Getting it out the other end wasn't so easy. Couple of hours prep got some oak board underneath it in the van as a sled and built a ramp out of stacked 2x5 and two scaffold boards. Called in a favour and got a couple of extra hands in for the main event. Smooth as silk and sitting in the garage on rollers now. Bed had a couple of Dink's but doesn't look worn at all. All the slides move freely with no backlash or play even though someone drove it into the chuck at some point. Zero movement in the spindle too. All dials are metric and has a Bearnard 3 jaw. Have a good collection of change wheels and collets but possibly missing some bits to secure the collets in the spindle. Both front and rear tool posts present and a few odds and ends I can't place yet. Tumble revers needs looking at. Looks to be complete but can't move the lever. Possible been tightened up and locked in place. Need to have the crossslide off too. Leadscrew turns under power but crossslide fails to engage the screw to power the slide.

Spent the last ten years at a goldsmiths as evidenced by the gold dust I'm seeing all over the bed. has a reconditioned plate fitted so its been worked on since new. Not far off to there workshop for advice. Half hour down the road for me (a factor in my purchase)

has a reconditioned plate fitted so its been worked on since new. Not far off to there workshop for advice. Half hour down the road for me (a factor in my purchase)

All in all very happy with my purchase. Just need to find a new home for my myford now. Can't keep both.

Didnt really have any passion for the ml1 but I'd love to get this beauty looking factory fresh again.

If anyone has had any experience with this lathe I'd welcome your advice as it progresses. First job. A good clean before anything gets removed.

Spent the last ten years at a goldsmiths as evidenced by the gold dust I'm seeing all over the bed.

has a reconditioned plate fitted so its been worked on since new. Not far off to there workshop for advice. Half hour down the road for me (a factor in my purchase)

has a reconditioned plate fitted so its been worked on since new. Not far off to there workshop for advice. Half hour down the road for me (a factor in my purchase)All in all very happy with my purchase. Just need to find a new home for my myford now. Can't keep both.

Didnt really have any passion for the ml1 but I'd love to get this beauty looking factory fresh again.

If anyone has had any experience with this lathe I'd welcome your advice as it progresses. First job. A good clean before anything gets removed.