You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

small angle grinder for wire brush use

- Thread starter bigegg

- Start date

bigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,675

- Location

- Leeds, West Yorkshire

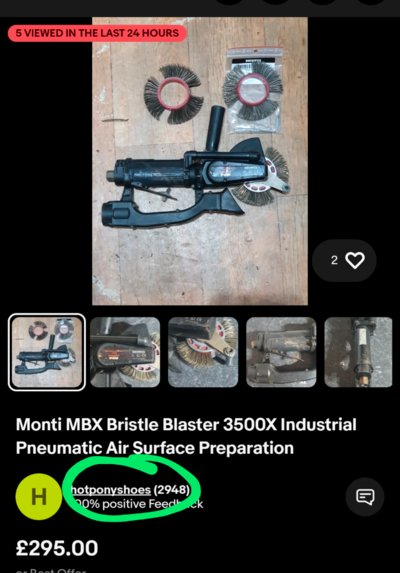

Monti Bristle Blaster?

'ow much?

Love one, but £400 is definitely out of my price range.

bigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,675

- Location

- Leeds, West Yorkshire

4 variable speed, so it states.....

Angle Grinder | Cordless Die & Side Grinders | Milwaukee Tool UK

Complete fabrication jobs quicker and easier with MILWAUKEE® Cordless Angle Grinders. These tools combine corded-like performance with cordless flexibility.uk.milwaukeetool.eu

Slowest is 10,000 rpm, up to 24500rpm.

I'm gonna give it a try, though.

bigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,675

- Location

- Leeds, West Yorkshire

id go down the flexable shaft stuff if you cant use a normal grinder

that includes the drill adapter and flexable shaft

The last time I used a flexible shaft (oo-er, Missus!), it seized up and ripped the drive motor down which smacked me in the head and almost laid me out cold.

I'm not a fan.

bigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,675

- Location

- Leeds, West Yorkshire

https://uk.milwaukeetool.eu/en-gb/m12-sub-compact-polisher-sander/m12-bps/ Have you seen this? 12v 0-2800 / 0-8300 RPM

Kram

Member

- Messages

- 8,521

- Location

- Sussex

Incorrect. Many current branded cordless grinders are at the 8500rpm speed, where as 80m/s would be 13k rpm, quite a difference.Any machine designed or sold to accommodate abrasive wheels will run at roughly 80m/s (actual rpm relates to diameter). The only way you will get a slower-running machine is to buy either a variable speed one or one that cannot take abrasive disks.

Power = torque x rpm, so the only way any small spinny thing can have enough power to do its job is to run at a gazillion rpm.

Small, powerful and slow-running is one of those "cannae change the laws o' physics" items.

115's apart from 3rd one is a 125mm.

hotponyshoes

Member

- Messages

- 7,945

- Location

- Somerset. Uk

Other sellers are available

Regarding the torque vs speed mentioned above,

I've got a brushless cordless grinder.

That's got 3 speeds.

I've not got any way of measuring it but I would say it has just as much torque at the lower speeds.

This would make sense to me as the torque will be determined by the motors rotor diameter (I think?)

The old school variable speed stuff certainly dropped torque at lower speed but I think that was to do with the speed controller.

Modern brushless stuff is basically a 3-phase motor running from a tiny vfd (again, I think) so can provide full torque at lower rpm.

Obviously work done = torque × rpm.

But, in practice, you can actually do more work with a wire brush at a lower speed as you can use higher pressure to dig in more.

At high speed you'll just skate across the surface.

bigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,675

- Location

- Leeds, West Yorkshire

https://uk.milwaukeetool.eu/en-gb/m12-sub-compact-polisher-sander/m12-bps/ Have you seen this? 12v 0-2800 / 0-8300 RPM

I've handled one in my local toolshop (geo spence, wortley, Leeds), and its basically their m12c cordless drill with a different end on it. I already have one of those, and its awkwardly shaped for working under a car

hotponyshoes

Member

- Messages

- 7,945

- Location

- Somerset. Uk

If you don't mind a pneumatic ones iv got the finixa version of the Monti Blaster,

Within the budget!

Within the budget!

Craig-SM

Member

- Messages

- 2,426

- Location

- Heckmondwike

No.

The do a straight, and a right angle, die grinder, and a "polisher", which is basically their m12 cordless drill without the clutch and a different chuck

Get the M12 Die Grinder in straight or right angle, depending on your preference. I have the right angle but I don't use it with a wire brush and instead the 3M bristle brush which remove rapidly and last surprisingly well.

mart

Member

- Messages

- 1,979

- Location

- South Yorks

@bigegg

I got a cable a few years ago. One end went in the drill, and you could put a small brush etc in the other end.I think there was sort of chuck to hold bits.The cable would would spin inside a sleeve. I still have in the garage.

This May be similar?

I got a cable a few years ago. One end went in the drill, and you could put a small brush etc in the other end.I think there was sort of chuck to hold bits.The cable would would spin inside a sleeve. I still have in the garage.

This May be similar?

bigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,675

- Location

- Leeds, West Yorkshire

@bigegg

I got a cable a few years ago. One end went in the drill, and you could put a small brush etc in the other end.I think there was sort of chuck to hold bits.The cable would would spin inside a sleeve. I still have in the garage.

This May be similar?

Yep.

That's the one that tried to kill me by seizing up as I was using it.

bigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,675

- Location

- Leeds, West Yorkshire

Milwaukee do a m12 tyre buffer which is a straight die grinder but slower speeds.

Might be worth looking at.

That looks perfect - *if* it will take standard wire wheels.

I shall investigate further.

bigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,675

- Location

- Leeds, West Yorkshire

Get the M12 Die Grinder in straight or right angle, depending on your preference. I have the right angle but I don't use it with a wire brush and instead the 3M bristle brush which remove rapidly and last surprisingly well.

I've ordered a bristle brush to try.

Thanks.

JOEPRO

Member

- Messages

- 5,349

- Location

- UK

I have both M12 right angle die grinder and the sander polisher.

The M12 die grinder is great, I use roloc accessories for it and some small wire wheels only where required for access. And of course as a die grinder when metalworking! Great tool. Mini roloc compatible flap discs are fantastic for weld dressing down in tight areas.

However, for stripping a car underbody unless you mean small localised areas, if you plan on doing the whole car with an m12 die grinder or tyre buffer(?) Its going to take a day or two. (Read weeks!) Ps I run through a 5 amp genuine battery in minutes stripping heavy underseal - or overheat the battery. So I have at least 6 batteries on rotation for heavy work.

Nothing beats a quality wire cup wheel on an M18 angle grinder for stripping old rubberised underseal from a car. Anything else is going to struggle. If you really want to use 2 inch wire wheels (not cup wheels but wheels) then a variable speed mains powered drill is your best bet for large areas to cover.

But again, I am not quite sure what specific problem you wish to solve. But for me it's an angle grinder as first choice.

Roloc brushes are going to be a very expensive and slow way to work on a car's underbody. They are not for that type of work. They are intended for gasket removal and surface preparation but any experienced mechanic won't use them on critical surfaces like engine gasket mating faces either.

The M12 die grinder is great, I use roloc accessories for it and some small wire wheels only where required for access. And of course as a die grinder when metalworking! Great tool. Mini roloc compatible flap discs are fantastic for weld dressing down in tight areas.

However, for stripping a car underbody unless you mean small localised areas, if you plan on doing the whole car with an m12 die grinder or tyre buffer(?) Its going to take a day or two. (Read weeks!) Ps I run through a 5 amp genuine battery in minutes stripping heavy underseal - or overheat the battery. So I have at least 6 batteries on rotation for heavy work.

Nothing beats a quality wire cup wheel on an M18 angle grinder for stripping old rubberised underseal from a car. Anything else is going to struggle. If you really want to use 2 inch wire wheels (not cup wheels but wheels) then a variable speed mains powered drill is your best bet for large areas to cover.

But again, I am not quite sure what specific problem you wish to solve. But for me it's an angle grinder as first choice.

Roloc brushes are going to be a very expensive and slow way to work on a car's underbody. They are not for that type of work. They are intended for gasket removal and surface preparation but any experienced mechanic won't use them on critical surfaces like engine gasket mating faces either.

bigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,675

- Location

- Leeds, West Yorkshire

There's very little/no underseal.I have both M12 right angle die grinder and the sander polisher.

The M12 die grinder is great, I use roloc accessories for it and some small wire wheels only where required for access. And of course as a die grinder when metalworking! Great tool. Mini roloc compatible flap discs are fantastic for weld dressing down in tight areas.

However, for stripping a car underbody unless you mean small localised areas, if you plan on doing the whole car with an m12 die grinder or tyre buffer(?) Its going to take a day or two. (Read weeks!) Ps I run through a 5 amp genuine battery in minutes stripping heavy underseal - or overheat the battery. So I have at least 6 batteries on rotation for heavy work.

Nothing beats a quality wire cup wheel on an M18 angle grinder for stripping old rubberised underseal from a car. Anything else is going to struggle. If you really want to use 2 inch wire wheels (not cup wheels but wheels) then a variable speed mains powered drill is your best bet for large areas to cover.

But again, I am not quite sure what specific problem you wish to solve. But for me it's an angle grinder as first choice.

Roloc brushes are going to be a very expensive and slow way to work on a car's underbody. They are not for that type of work. They are intended for gasket removal and surface preparation but any experienced mechanic won't use them on critical surfaces like engine gasket mating faces either.

I'm just taking off bits of surface rust prior to fixing.

It's a Landcruiser Amazon so lots of books/crannies.

I'm using a 4.5in mains powered angry grinder for the bulk of the work, but there's certain areas (usually on top of the chassis, near body mounts) and around suspension parts.

Shedendman

Member

- Messages

- 5,606

Guess what i bought

And from that bloke

You wont get into every corner though,and does gulp a lot of air

But bloody hell its wicked