pressbrake1

Member

- Messages

- 5,553

- Location

- Essex

Dsg came with three fixed steadies and a travelling. Had to make one for the lang and the monarch came with a broken one.Henry is looking on with interest. Nice lathe indeed, hope he got a travelling steady with a bed that long.

Tbh most of my work is geo technical or hydraulic so big stuff only so no need for a travelling steady ,fixed only is the order of the day

it would probably take a week just to get it out

it would probably take a week just to get it out

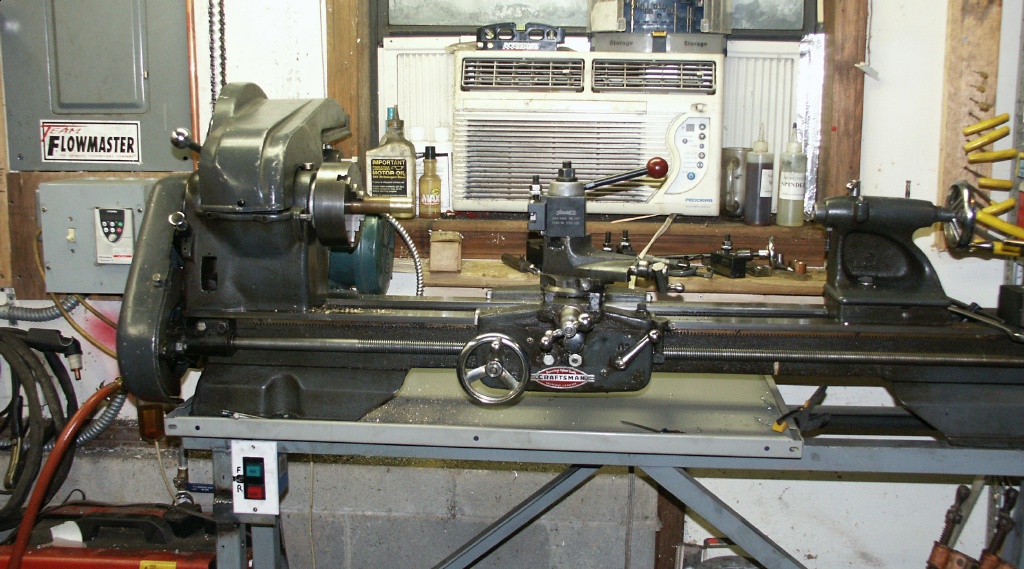

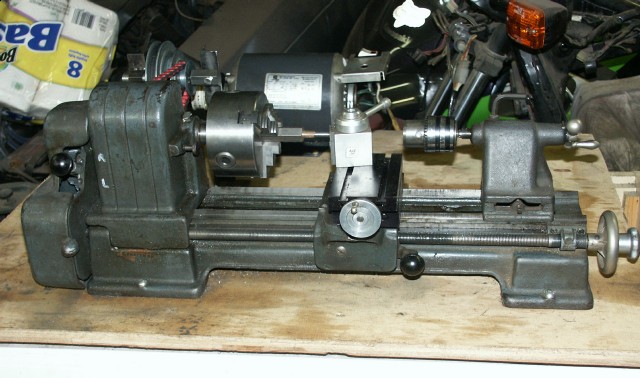

), I got a couple quick pics to put on here.....

), I got a couple quick pics to put on here.....