hi every one' just sort off fishing for ideas im building a hybrid 16v mini and have to weld two different drive shafts from different cars together have looked into this abit and some of the main probs are twisting and snaping.they way other people seem to do them is machine sort of a step out shaft then weld then sleve then weld.will prob end up doing it like this but just wondered if any body on here knew of a better way

ive looked into having some shafts made out of en24 and billet cheapest was about £250 well out of my budget so think im gonna get a couple of sets and practice and test se witch ones do the job

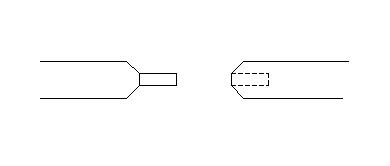

ive looked into having some shafts made out of en24 and billet cheapest was about £250 well out of my budget so think im gonna get a couple of sets and practice and test se witch ones do the job . Also a pain to weld. I meant a radial vee with a flat tip. In fact a better prep - depending on the size of the stub might be a j-prep, which could save time and weld metal.

. Also a pain to weld. I meant a radial vee with a flat tip. In fact a better prep - depending on the size of the stub might be a j-prep, which could save time and weld metal.