Good evening peeps, newbie to the site and yes you’ve guessed it “ Houston we have a problem “.

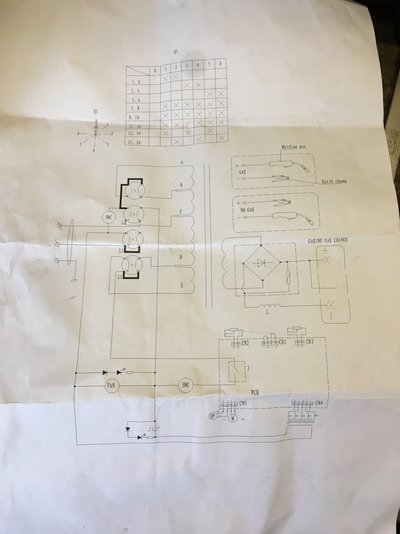

I’ve had my welder for a good few years now and apart from replacing the torch and cable it’s been spot on. Then today midway through welding a panel it just stopped. The fan still runs but on pulling the trigger nothing , no gas , no click , no wire nada. Unfortunately I’m not that technically aufait it works or doesn’t ooops. So basically in layman’s terms I’m hoping that maybe some kind soul may be able to shed some light on the problem. Many thanks in advance

I’ve had my welder for a good few years now and apart from replacing the torch and cable it’s been spot on. Then today midway through welding a panel it just stopped. The fan still runs but on pulling the trigger nothing , no gas , no click , no wire nada. Unfortunately I’m not that technically aufait it works or doesn’t ooops. So basically in layman’s terms I’m hoping that maybe some kind soul may be able to shed some light on the problem. Many thanks in advance