rockweasel

Member

- Messages

- 995

- Location

- none

Elliot Progress 1 Drill.

"I'll just widen this hole a little." It was awkward to clamp the piece down, so I held on to it (gingerly) with my bad hand. The drill bit caught the hole and spun it out my grip. By the time I'd turned it off a few things had bent out of shape. Stupid mistake.

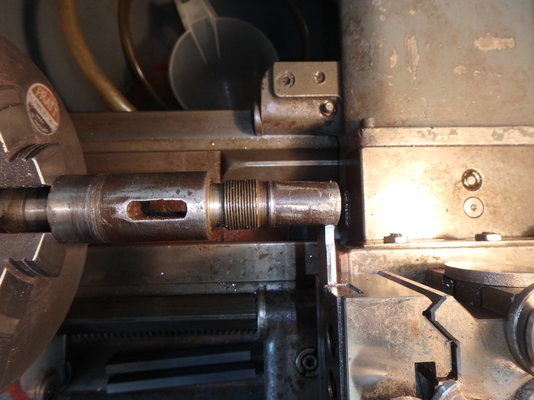

The item I'm pointing at in the photo is bent. Is this the spindle?

If so: Can I straighten it (or have it straightened), or do I need to source a replacement?

TIA

"I'll just widen this hole a little." It was awkward to clamp the piece down, so I held on to it (gingerly) with my bad hand. The drill bit caught the hole and spun it out my grip. By the time I'd turned it off a few things had bent out of shape. Stupid mistake.

The item I'm pointing at in the photo is bent. Is this the spindle?

If so: Can I straighten it (or have it straightened), or do I need to source a replacement?

TIA