dobbslc

Member

- Messages

- 10,909

- Location

- Hertfordshire UK

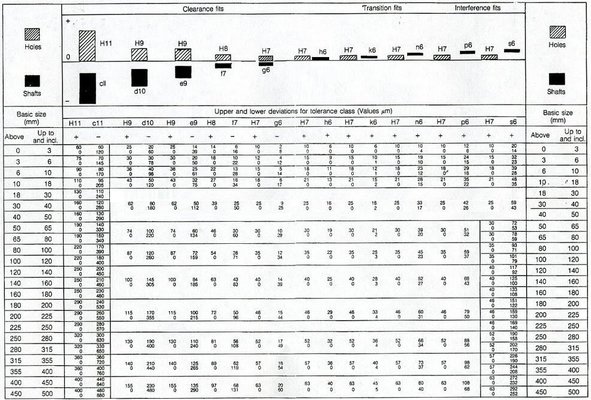

I have a turning job for a mate that involves a press fit of a sleeve onto a suspension ball joint with nurling on it. Is there any kind of dimension to work to per millimetre of diameter for a good tight fit?

Here's a picture of the parts.

It's going to be made into a wishbone for a car.

Here's a picture of the parts.

It's going to be made into a wishbone for a car.