Hood

I am obsessed.

- Messages

- 17,712

- Location

- Carnoustie, Scotland

Not sure if this is the place to post this or even if such an enquiry should even be asked on a welding forum  I know there are a lot of people here with all sorts of knowledge and experiences from different disiplines so...

I know there are a lot of people here with all sorts of knowledge and experiences from different disiplines so...

What I am wanting to do is make up a compact sensor (for the want of a better word) to inform a CNC control of the position of a lathes tool change turret.

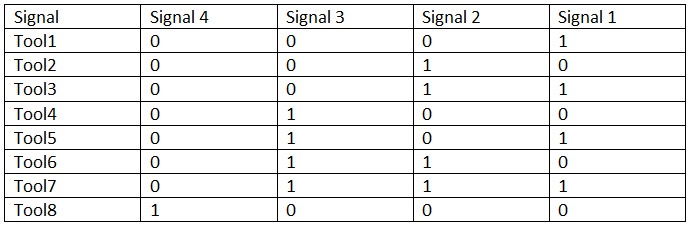

The turret has 8 positions so I was going to use 4 signals/sensors/switches and use binary to define the positions, table below shows what I mean.

I have a few options for doing this which are easily within my capabilities but they are not as compact as I would like.

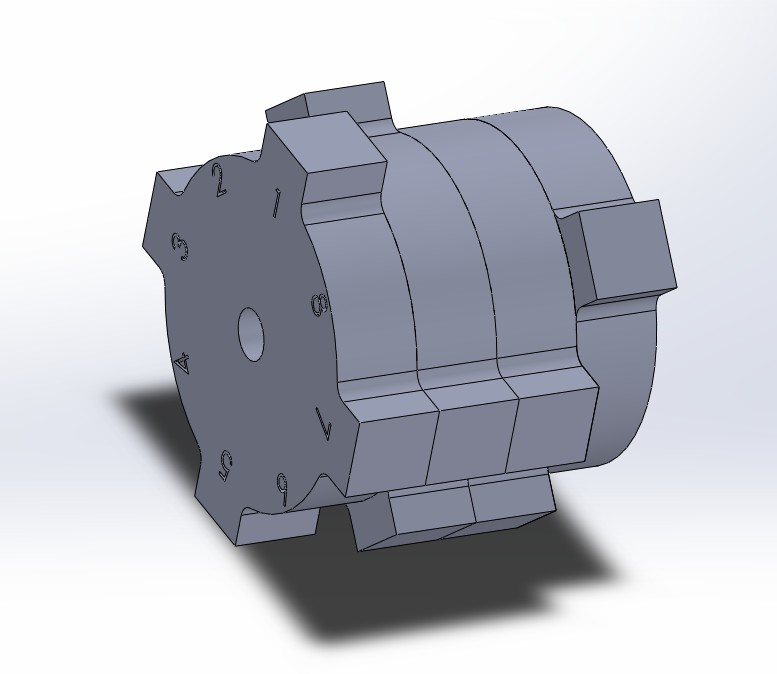

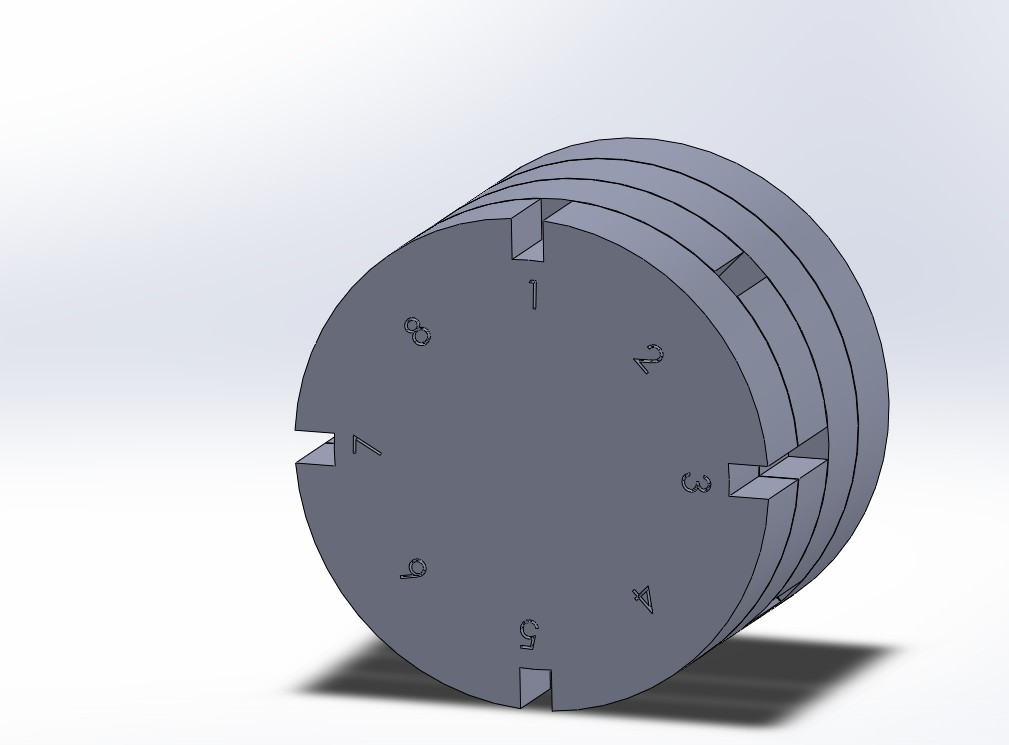

1 option would be to use prox switches and make up a disc with either holes or triggers (depending on prox type) on the periphery such as in the pics below.

I could also use micro switches with similar trigger drum, just have to make the transitions more of a cam shape.

The micro switches would probably be the more compact as they would allow me to have a slightly narrower cam/trigger wheel as switches are about 6.5mm wide where the prox's I have are 8mm thread so 10mm per prox would be required.Also the length of the prox's are much more than the height of the micro switches. Prox however would probably be more resillient in the long term and certainly easier to adjust if that were required.

I was however thinking of making up a slotted disc, sort of like an encoder disc and using optical switches but so far I have not really found anything suitable and that is the reason I am posting here.

Using 4 slotted optical switches would likely not make things any more compact as the size of the disc would have to be quite large to accomodate them so I was wondering if anyone knew of a single bodied switch with 4 optos built in. I have done a Google search but my terminology is obviously wrong as I keep getting hits for network switches

I really need the optos to be able to handle 24v from the sourcing Input of the CNC and I am not really great with electronics so I am not sure if such a thing even exists. I could probably however use an optocoupler such as the PC817 I have used in the past to convert 5v encoder signals to 24v for sinking inputs on a CNC control.

I know there are a lot of people here with all sorts of knowledge and experiences from different disiplines so...

I know there are a lot of people here with all sorts of knowledge and experiences from different disiplines so...What I am wanting to do is make up a compact sensor (for the want of a better word) to inform a CNC control of the position of a lathes tool change turret.

The turret has 8 positions so I was going to use 4 signals/sensors/switches and use binary to define the positions, table below shows what I mean.

I have a few options for doing this which are easily within my capabilities but they are not as compact as I would like.

1 option would be to use prox switches and make up a disc with either holes or triggers (depending on prox type) on the periphery such as in the pics below.

I could also use micro switches with similar trigger drum, just have to make the transitions more of a cam shape.

The micro switches would probably be the more compact as they would allow me to have a slightly narrower cam/trigger wheel as switches are about 6.5mm wide where the prox's I have are 8mm thread so 10mm per prox would be required.Also the length of the prox's are much more than the height of the micro switches. Prox however would probably be more resillient in the long term and certainly easier to adjust if that were required.

I was however thinking of making up a slotted disc, sort of like an encoder disc and using optical switches but so far I have not really found anything suitable and that is the reason I am posting here.

Using 4 slotted optical switches would likely not make things any more compact as the size of the disc would have to be quite large to accomodate them so I was wondering if anyone knew of a single bodied switch with 4 optos built in. I have done a Google search but my terminology is obviously wrong as I keep getting hits for network switches

I really need the optos to be able to handle 24v from the sourcing Input of the CNC and I am not really great with electronics so I am not sure if such a thing even exists. I could probably however use an optocoupler such as the PC817 I have used in the past to convert 5v encoder signals to 24v for sinking inputs on a CNC control.