brewdexta

The biggest tool in the box

- Messages

- 5,747

- Location

- UK

As per my user name, I brew beer as a hobby. As the kit is mostly on the level and there are processes where I recyle the wort between heat exchanger and mash tun then I need pumps.

Small brewing pumps are expensive noisy and generally cr@p at priming and being able to keep them clean. The pumps also need to be able to withstand boiling water. Currently I'm using 12v pumps that are used to recirculate boiling water arounf solar thermal panels, cheap and adjustable but you cant take 'em apart to clean them. I've also tried flojet pneumatic pumps and a Totton, I haven't tried a march may which are over 200 quid but by all accounts they are onlys slightly better.

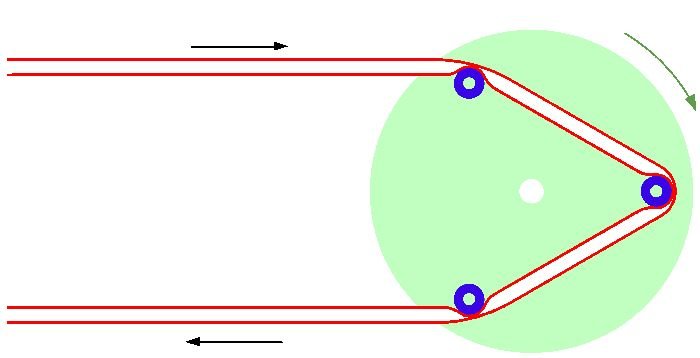

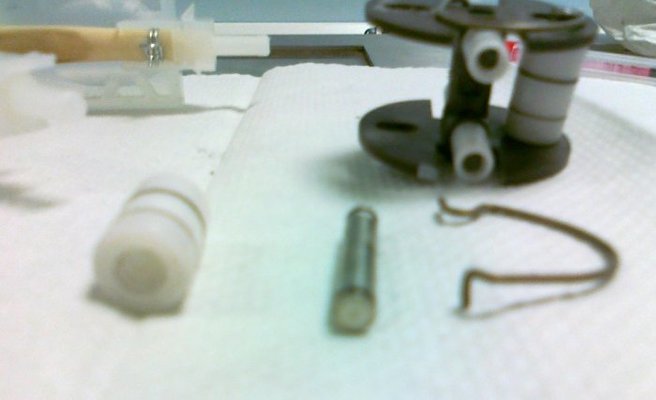

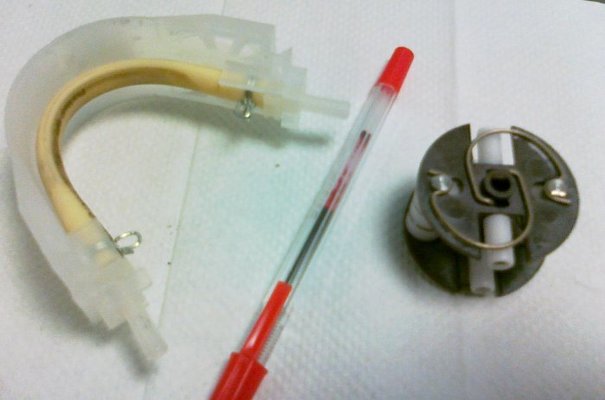

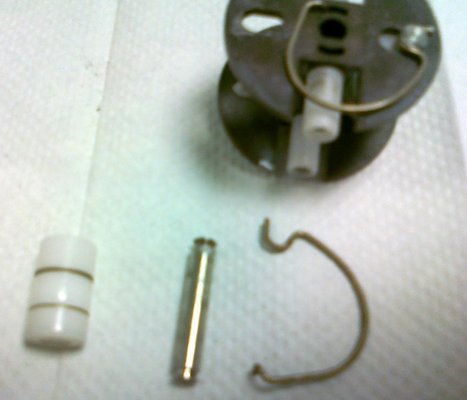

One guy converted some Landrover brake drums into a pair of peristaltic pumps. These are the kind of pumps that are used for kidney dialysis and precise dosing in chemical processes. Basically they are a piece of flexible pipe in a cylindrical holder and a rotor goes around squeezing the pipe, pushing the liquid around. Chemical/medical pumps tend to be very expensive and only a few litres per hour, I need them to variable between 2 and 10 litres per minute. With only a length of pipe in contact with the liquid then they are extremely easy to clean and prime easily.

I'm at the early design phase, something similar to brake drums but in alloy would be a good start, probably 8 to 10" diameter. Then I need a motor that I can adjust in speed with quite low revs, probably geared down. I will have to experiment to work out the exact flow, I will probably be using 1/2" bore silicon tube and probably 3 or 4 rollers on the rotors to minimise pulsing. Silicon tube doesn't collapse at boiling water temp and its what all my brewery is plumbed in.

Andy ideas on sourcing parts cheaply welcome

Cheers

Andy

Small brewing pumps are expensive noisy and generally cr@p at priming and being able to keep them clean. The pumps also need to be able to withstand boiling water. Currently I'm using 12v pumps that are used to recirculate boiling water arounf solar thermal panels, cheap and adjustable but you cant take 'em apart to clean them. I've also tried flojet pneumatic pumps and a Totton, I haven't tried a march may which are over 200 quid but by all accounts they are onlys slightly better.

One guy converted some Landrover brake drums into a pair of peristaltic pumps. These are the kind of pumps that are used for kidney dialysis and precise dosing in chemical processes. Basically they are a piece of flexible pipe in a cylindrical holder and a rotor goes around squeezing the pipe, pushing the liquid around. Chemical/medical pumps tend to be very expensive and only a few litres per hour, I need them to variable between 2 and 10 litres per minute. With only a length of pipe in contact with the liquid then they are extremely easy to clean and prime easily.

I'm at the early design phase, something similar to brake drums but in alloy would be a good start, probably 8 to 10" diameter. Then I need a motor that I can adjust in speed with quite low revs, probably geared down. I will have to experiment to work out the exact flow, I will probably be using 1/2" bore silicon tube and probably 3 or 4 rollers on the rotors to minimise pulsing. Silicon tube doesn't collapse at boiling water temp and its what all my brewery is plumbed in.

Andy ideas on sourcing parts cheaply welcome

Cheers

Andy

)

)